-

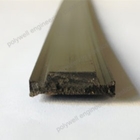

Thermal Break Strip

-

Polyamide Nylon 66

-

Glass Filled Nylon 66

-

Broken Bridge Aluminum Window

-

Plastic Moulding Dies

-

Nylon Extruder Machine

-

Single Screw Extruder

-

Pipe Production Line

-

Plastic Extrusion Machine

-

Aluminum Cutting Machine

-

Plastic Granulator Machine

-

Tensile Testing Machine

-

Laser Code Printer

-

Water Bottling Machine

-

Mr. Paolo CelaniThank you very much for very good news! We appreciate your honesty and collaboration. You have supplied good dies, all sizes within tolerance. We have ordered dies for a total amount of more than 200,000 USD and we are continuing to order. Thank you again to you and your very professional team.

Mr. Paolo CelaniThank you very much for very good news! We appreciate your honesty and collaboration. You have supplied good dies, all sizes within tolerance. We have ordered dies for a total amount of more than 200,000 USD and we are continuing to order. Thank you again to you and your very professional team. -

Mr. Martyn HainesThank you for your help with this order and if ever you need someone to tell customers how helpful you are just tell them to contact me.

Mr. Martyn HainesThank you for your help with this order and if ever you need someone to tell customers how helpful you are just tell them to contact me. -

Mr. Dietmar DürrI received your samples. I agree to Mr. Wölki, they looks pretty good. We will arrange the balance payment. Please pack the mold and send them asap.

Mr. Dietmar DürrI received your samples. I agree to Mr. Wölki, they looks pretty good. We will arrange the balance payment. Please pack the mold and send them asap.

Thermal Break Material, Polyamide Heat Insulation Barrier Strip For Thermal Break Aluminium Windows

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Polyamide66 Reinforced By 25% Glass Giber | Color | Black |

|---|---|---|---|

| Application | Thermal Break Aluminum Windows | Port | Shanghai |

| Production Capacity | 100000 M/Day | Technical Performance | GB/T 23615.1-2009 |

| Transport Package | Roll Or Linear | Shape | As Drawing |

| High Light | plastic extrusion profiles,thermal break insulator |

||

Production Description

Broken bridge aluminum insulation strip is an important criterion for distinguishing aluminum alloy doors and windows and broken bridge aluminum doors and windows. It is precisely because of the appearance of broken aluminum insulation strips that the aluminum doors and windows of the broken bridge have good thermal insulation and sound insulation performance.Over the years, polyamide heat-insulation strip has been widely used in glass curtain walls due to its good properties and low cost. Especially Polyamide 66 reinforced by 25% glass fiber thermal break strips, they are inserted into aluminum window, door and facade profile for thermal insulation.

![]()

![]()

![]()

![]()

Advantages

1.Effectively increased thermal in the system property insulation.

2.Reduces condensation on the window.

3.Sound insulated.

4.Improve comfort and living condition.

5.Possible double color coatings provide better aesthetic effect.

6.Various shapes will be designed for the customer's requirements.

7.The working temperature of the thermal insulation strip is 220°C, Melting Point reaches to 246°C. This enables coating process after assembly of composite profiles.

8.High corrosion-resistance, weather-resistance, heat-resistance, alkali-resistance and long life of usage.

9.linear thermal dilation coefficient almost identical to that of aluminium profiles.

![]()

![]()

![]()

![]()

Characteristic

According to different storage time and ambient climate, the dimension of PA strips will increase slightly because of the natural moisture absorption. And the mechanical properties will change slightly too.

So, PA strips should be transported and stored under dry conditions away from the influence of weather. (rain, direct sunlight etc.)

![]()

Polywell PA66 GF25 thermal barrier strips Performance Table

|

No. |

Item |

Unit |

GB/T23615.1-2009 |

GB/T23615.1-2017 |

|

|---|---|---|---|---|---|

|

1 |

Density |

g/cm3 |

1.3±0.05 |

1.30±0.05 |

|

|

2 |

Linear expansion coefficient |

K-1 |

(2.3-3.5)×10-5 |

(2.3-3.5)×10-5 |

|

|

3 |

Testing for tensile cracks |

— |

No crack in orifice |

No crack in orifice |

|

|

4 |

Shore hardness |

— |

80±5 |

80±5 |

|

|

5 |

Tensile modulus |

MPa |

≥4500 |

≥4500 |

|

|

6 |

Elongation at break |

% |

≥2.5 |

≥3 |

|

|

7 |

Vicat softening temperature |

℃ |

≥230 |

— |

|

|

8 |

Melting peak temperature of DSC |

℃ |

— |

≥255 |

|

|

9 |

Temperature of deflection under load |

℃ |

≥240 |

— |

|

|

10 |

Impact strength(Unnotched) |

KJ/㎡ |

≥35 |

— |

|

|

11 |

Low temperature impact strength(Unnotched) |

KJ/㎡ |

— |

≥50 |

|

|

12 |

Tensile strength(longitudinal) |

MPa |

≥80 |

≥90 |

|

|

13 |

Tensile strength(transverse) |

I(Cross section height<20mm) |

MPa |

≥70 |

≥90 |

|

I(Cross section height ≥20mm) |

|

— |

≥80 |

||

|

Non I shape |

|

— |

≥25 |

||

|

14 |

High temperature tensile strength(transverse) |

I(Cross section height<20mm) |

MPa |

≥45 |

≥55 |

|

I(Cross section height ≥20mm) |

|

— |

≥45 |

||

|

Non I shape |

|

— |

≥20 |

||

|

15 |

Low temperature tensile strength(transverse) |

I(Cross section height<20mm) |

MPa |

≥80 |

≥90 |

|

I(Cross section height ≥20mm) |

|

— |

≥80 |

||

|

Non I shape |

|

— |

≥25 |

||

|

16 |

Water resistance tensile strength(transverse) |

I(Cross section height<20mm) |

MPa |

≥35 |

≥85 |

|

I(Cross section height ≥20mm) |

|

— |

≥75 |

||

|

Non I shape |

|

— |

≥22 |

||

|

17 |

Aging resistance tensile strength(transverse) |

I(Cross section height<20mm) |

MPa |

≥50 |

≥60 |

|

I(Cross section height ≥20mm) |

|

— |

≥55 |

||

|

Non I shape |

|

— |

≥20 |

||

|

18 |

Typical values of thermal conductivity |

Heat Flow Meter Method |

W/(m·K) |

— |

0.3 |

1.Sample water content less than 0.2% by weight.

2.Norm laboratory condition:(23±2)ºC and (50±10)% relative humidity.

3.The specifications marked with "a" only applies to I-shape strip otherwise, the specifications concluded between supplier and buyer through consultation, shall be written in contract or purchase order.

![]()

![]()

Storage Conditions

First, Store profiles horizontally in order to prevent bending or twisting the material, otherwise long storage periods cause permanent sagging. Support long lengths.

Second, Maintain ambient temperature in the range from 15 to 20 °C.

Third, Protecting against moisture.

Delivery

For common specifications, we have molds , we can send out the strips in 10-15 working days after receiving the payment.

For special specifications, we have no molds. We need to produce the mold first. Customer should pay for the mold cost.

Packages

For all specifications, they could be packaged in linear, customer can decide the cutting length.

For the simple specifications like shape 'I' and shape 'C', they can be packed in rolls. Usually 300-600 meters/roll.

![]()

Our Service

1. Expertise in the production of standard polyamide thermal break strips.

2. Respect customers' needs, provide customized products, try best to satisfy customers' requirements.

3. Fast service and on-time delivery

4. Strict quality control system, each production process will be strictly supervised by us.

5.We can provide all products on the insulation strip production line and the technical support.

Our Company

![]()