Жаңырек архитектуралык дизайндардын энергиянын жыйындылыгы жана узук жылуusu эле термод шок жолдоруна байланыштуу. POLYWELL клиенттерине стандартга чейин жана оң жобоюндо термод шок жолдору төөлөө үчүн высокой точносткан формалар жасоо мүмкүнчүлүгүн берет. Учурлар, каптар жана панорамалык стеналарда колдонулатын ошондой эле жолдор сыр материалдардын кичирүүсүн карашуу үчүн высокой точносткан формаларга жарыялашуу керек.

Экструзия формаларын жасоо кезинде көрсөткөн мeseликтөр

Термик ар кычмылары сыр сламптардан пайда болгон жана шыңкүчтүү эле, бул естетилген жана алынгы өзгөртүүдүн негизги компоненттерине жол берет. POLYWELL бул маселени чечүү үчүн сатуучулар тарафынан берилген изделерге ээ болбойт, акыркы эле терс кычмактуу бандыктардын иштеп чыгуусуна тийишли башка факторлорду да эсептейт.

Эч кандай материалдин өзгөчөлүүсү: Термик ар кычмылардын иштеп чыгуусундагы маанилүү жакты

Термик ар кычмалар үчүн колдонулатын .haraktirистикасы бар эч кандай материал шыңкүчтүү characteristics-ка ээ, ал manufacturing процессиндеги формада проблемаларга туурат. POLYWELL дагы тажырат жана тазы көчтөрү бар эмес, анткени ошоу үчүн аныктап берген gap ratios-дарды таяныштык ретте коюп жатат.

Таза форманын температурасын эсептөө: Форманын құруы үшін қажетті өзгертулер

Калдырмалар үчүн суу жөнгөктөө мәліметтерин кийинки шыңкышка ээ болгондо кеңейтүүге туура келет. Берилген бөлмөлөрдүн аягындагы сыймыктын соңку сапына тигиши бар экенин караңыз, мыс алдында термик ар кылуучу жумуштарынын маанилүү булмаңыз.

Термик Ар Кылуучу Жумуштары Үчүн Экструзия Калдырмалары: Сизге Билишиниз Керек Неше Соз

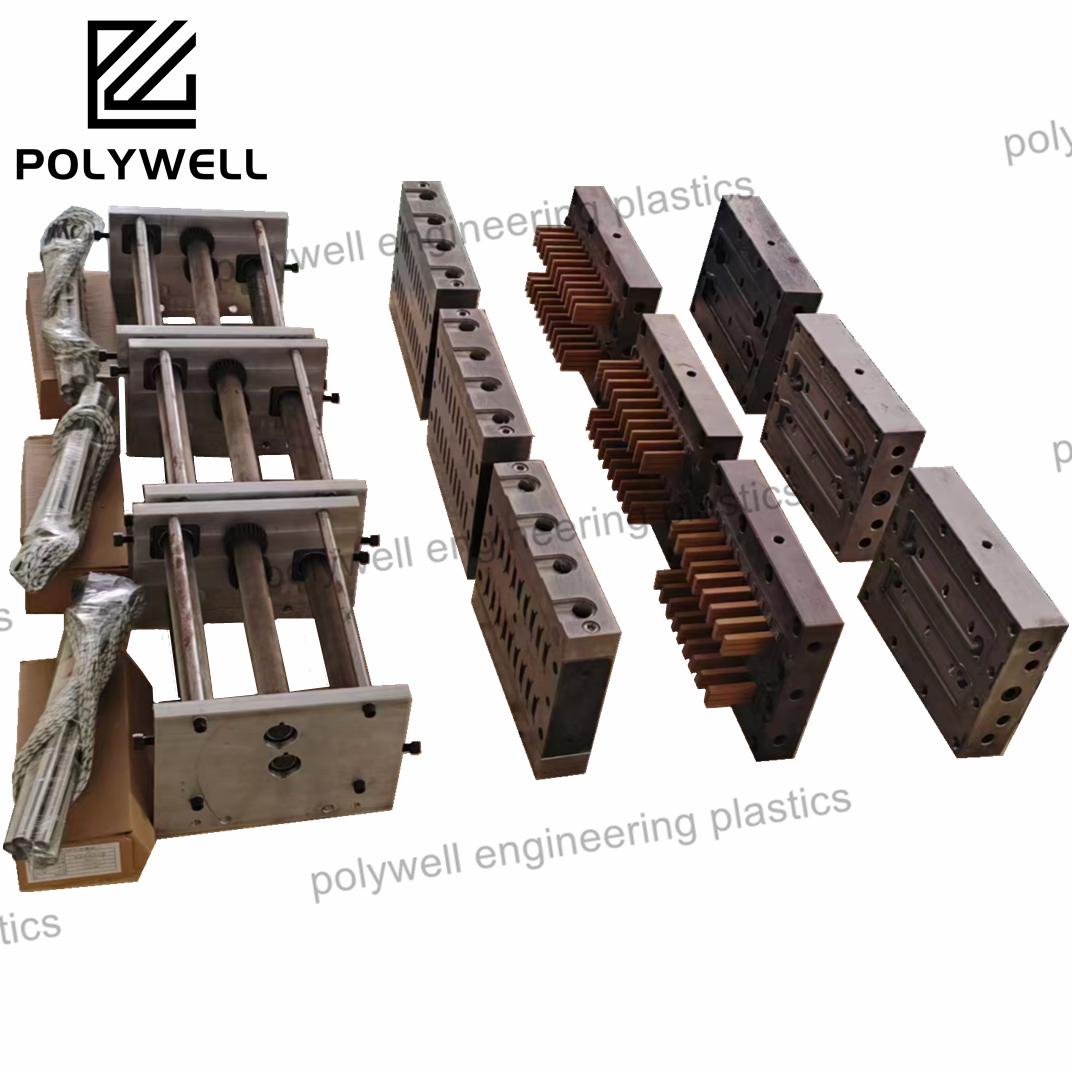

POLYWELL - термик ар кылуучу жумуштарын жасайт жана үч түрдүү калдырма түрүн суранат. Алар дегенде:

1. Базалык Калдырмалар: Бул калдырмалар жумуштардын сапын аныктайт, чунку антамдын базасын түзөт. Экструзия процессинде дефекттер келишет деп, калдырмалардын калибрировкасына көмөк кылынат.

2. Инъекциялык Калдырмалар: Бул инъекциялык калдырмалар таянмастан туратын заманда таянчтык дизайнерлерди жана түзүмдердин көбөйтүүсүн жеңишке туура келет. Бул калдырмалар таянчтык дизайнерлер менен түзүмдерди колдонот, бул ушул эле ар кандай аныктуу болуп саналат PRC-дан дүрөө экструзиясынан.

3. Композиттүү формалар: Бул формалар эсас түшүнчөлөрдүн жана иньекция формаларынын көмбайнасы болуп саналат, чунку мисокелердин бардык маанилүү талаптары бар.

Неге Форма Көз алаттууunda Тагыма Тәжимдүү Өткөнүңуз Жакшы

Экструзия формаларынын дизайны эле артыстик, эле зерттече. Материалдын ниспесин кемири жана көбөрүүгө тийиш келген чейинки түзүмдүү өзгөртүүлерди жасоо көп жылдык физикалык жумуштан чыгарылат, мысалы, POLYWELL-дин белгилүү жумушу. Анын элдик жумушу технология менен жана сектордун билимдеринен туусунан тууралуу.