Уралык жолдо куруштуу өндөрүлөрү үчүн, мышыктуу кылуу жана дизайнын чейин келүү саламат. Бул мақсатка ээ болуш уچун POLYWELL экструзия формасын пайдаланып, мышыктуу жолдо курууга жана даяр экструзия формасына жетүү үчүн тиешелүү тәртيبдөйүн берет.

Анын ар бир инде, энергияны сактоо үзүндүгүнө орноч болгон ыктымалдыктердинен эе, булардын энергиясын сактоо үчүн thermal breaks бизге керек болуп келген. Улардын коьомгой пайдаланышу менен, термостриплорду POLYWELL-дан пайдаланып, дөрдөлөгөн профилдерге кирип, керек узундугу боюнча кесилет. Эң жеңишке алып, термостриплор термик интерференция жасайды жана ыкмалардын жана терезелердин ичинде жылдыз өткөрүүсүн туташканда.

Экструзия процессини жүргүзгөндө, кадамдарды толук түрдө колдонуу керек:

Ишти ыстыктуу менен баштаңыз: Резина немесе термопластик жылдыздарды ыстыктуу менен даярдаңыз, аларды формалауу үчүн азыр.

Тамга Көчүрүүнү Натыйжалаңыз: Акыркы тапшырма болуп, чыныгы резинаны жылдыраңа алып, содуңо көрсөткөн өмүрүңүзгө чейир берүү үчүн резинаны ишлеү молдурууга сулуңуз.

Жырдамдашуу жана Бөлүү: Материал экструзиядан кийин жырдамдашып, строительство мақсаттары үчүн керек узундукка бөлүп, экилгенге дейінгі.

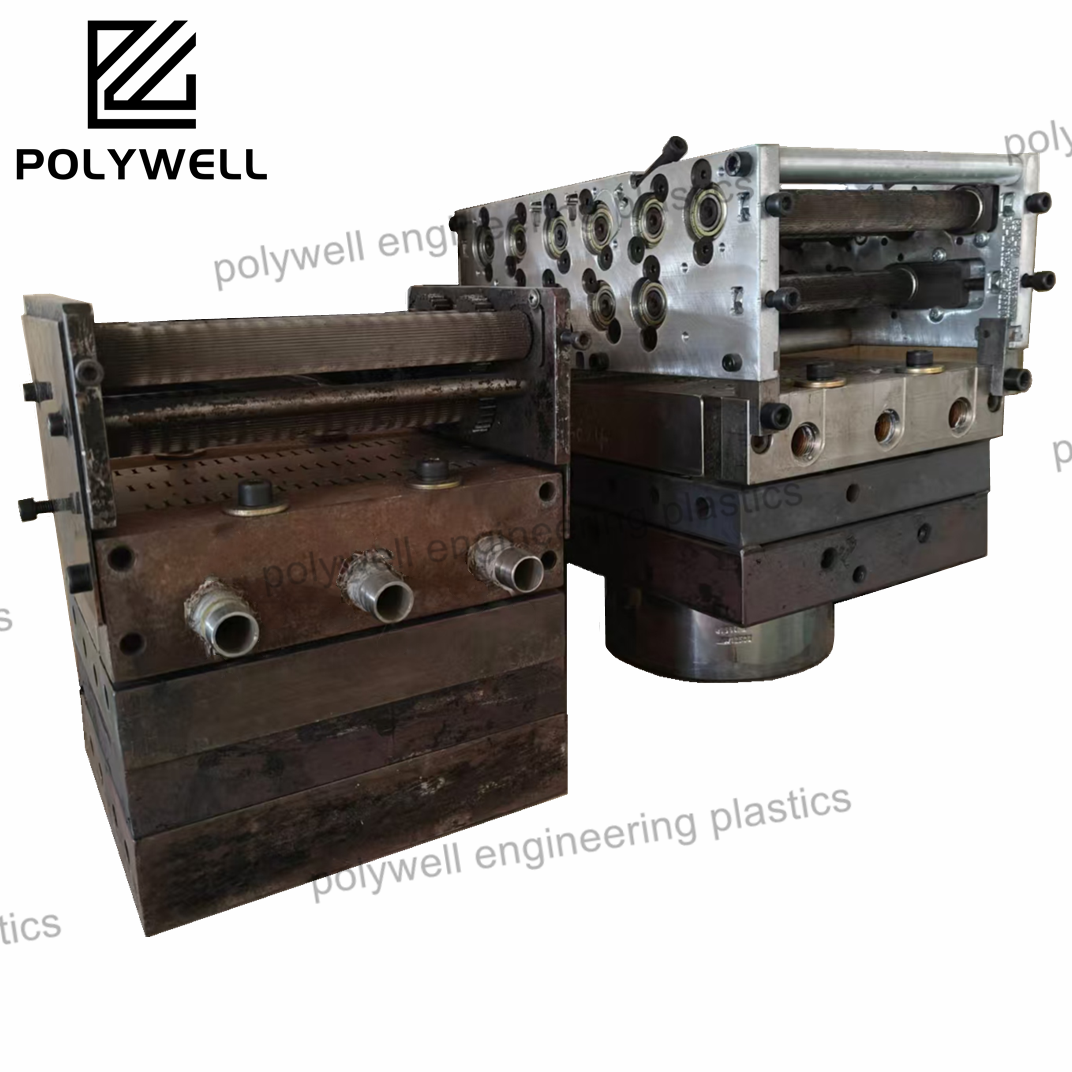

POLYWELL Экструзия Молддарынын Үчүнчү Айрымдары Экструзия молддарынын POLYWELL-дин ар биринен башкаланышы термик аяктоорлорду ишке ашырууда эфективдик жана дүрөөдүк караганда бирокой ар биринен башкаланышы. Ушул characteristics-тер POLYWELL-ди индустриядагы башкасынан айрып chygaryshynda:

Бирокой Сыйлоо Молддору Консистент Чыгаруу үчүн: POLYWELL-дин молддору дүрөөдүк үчүн жасалган, бул размерди, форманы жана бирокой аяктоордуун эмне жана жардамын берет. Ушул тууралуу термик аяктоорлорду ишке ашырууда энергиянын эфективдигин анткени маңызды.

Күчөк жана узун аралык: Биздин экструзия формалары субеттеги материалдардын көмөгү менен эмне-бирдикке ырааттуу болуп, экструзия процесининг тяжел characteristics-ка каршы чыгару сапасын сактоо мүмкүн.

Энергиядан тас жеткиликтүүлүк: POLYWELLдин гадирли экструзия формаларында пайдаланылатын индустриялык thermal break-тар материалдардын жыйынтыгын жана энергиядан тас жеткиликтүү эмиссияларды көбүрөөк жеңиштирип, thermal break жолдору изоляцияда эфективдүү болуп, жөнөтүүчү жана экологияга даяр колдонулушу бар.

POLYWELL тарыхындагы экструзия формаларынын түрлөрү Бардык түрдөгү экструзия формалары thermal break жолдору үчүн маанилүү талаптарга сөйөнөтүлөт. Көлөгөндер булар:

Аскер формалары: Анын көмөгү менен изоляциянын жыйынтыгына да кийинки профилде экономикасы да тууратуу болгон жерде база жолдоого профиль түзүү үчүн колдонулат.

Инъекция формалары: Анын көмөгү менен жолдоогондукка рanga, текстура жана артыкча изоляциянын қасиеттерин кошкон polymer модифицируется.

Чыктык шаблондоро: Бул шаблондоро чыгыш сыйлыктары кеминде температураларда жанашип алатын материалдар менен колдонулат. Бул экстра элекchied feature эмес.

Термик жарытту бендигиндеги өнүктөрдүн көрсөтүүсүнө POLYWELLдин экструзия шаблондорунун колдонулушу жыйынтык жана эфективдик аркылы эң чондоого. Максаттардан түшүнүп, ээчилелген шаблон технологиясы колдонулуп жана өзгөчө шаблондоро көрсөтүлүп, энергиянын ээчилелгендүү өнүктөсүндө өнүктүн чоңдукка туурат.