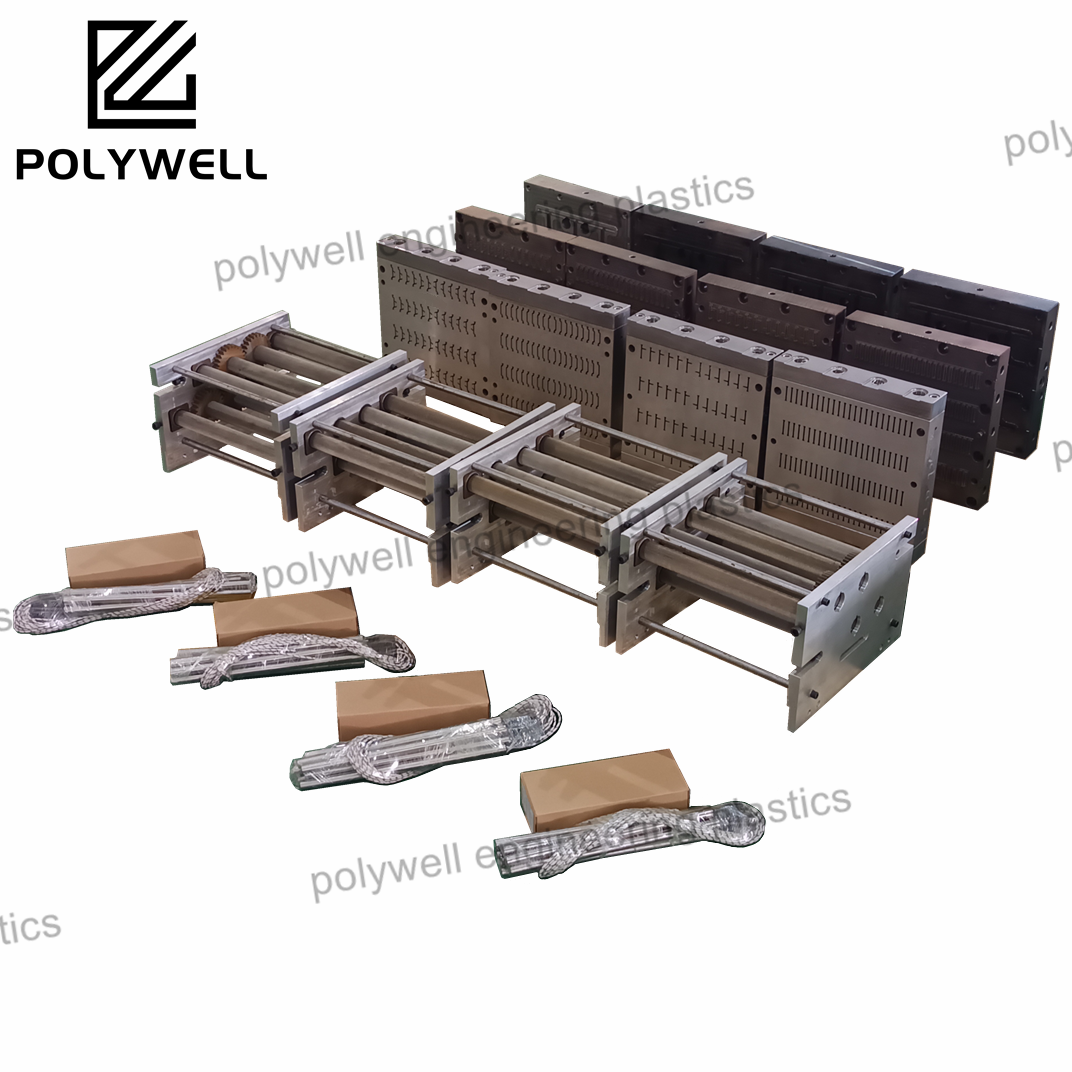

Kev tsim tawv hlau lossis tawv roj tshuaj uas muaj qhov tov lossis qhov chaw nyiag nyav hauv nws yog kev tsim tawv hlau lossis tawv roj tshuaj uas tsim tawv hlau lossis tawv roj tshuaj uas muaj qhov tov lossis qhov chaw nyiag nyav hauv nws. Qhov nyuaj ntawm txoj kev no yog nyob rau hauv qhov kho tawv, uas yuav tsum tsim ib txoj kev cim ncaj ncees thiab qhov chaw hauv nruab nrab tawv tshiab tib lub sijhawm. Hauv kev tsim tawv roj tshuaj, cov neeg ntau tias ua tau los ntawm kev siv tawv plaub ncav lossis tawv roj tshuaj. Tawv plaub ncav siv ntau yam "ntxiav" los pab tawv roj tshuaj hauv qab tawv. Lub roj tshuaj kub dej dhau ntawm cov ntawv no thiab rov muab ntxiv (lossis "roj tshuaj") hauv qhov chaw muab ntxiv ua ke ua ntej tawm ntawm tawv. Qhov tseeb ntawm kev rov muab ntxiv no yog qhov tseem ceeb, vim tias qhov muab ntxiv tsis zoo tuaj yeem yog qhov chaw nyiag nyav. Lossis, rau cov khoom siv tsawg dua, tawv roj tshuaj uas muaj roj tshuaj tawm ntawm sab nraud tuaj yeem siv los tiv thaiv qhov muab ntxiv. Hauv kev tsim tawv hlau, ib txoj kev sib xws siv tawv porthole lossis tawv roj tshuaj, qhov hlau hlau raug faus ua ob qhov chaw uas dhau ntawm tawv roj tshuaj thiab tom qab no muab ntxiv ua ke hauv zog siab thiab kub hauv qhov chaw muab ntxiv ua ke ua ntej tawm ntawm tawv. Kev tsim tawv hlau tawv tshiab xav tau kev daws teeb meem zoo li kub, zog thiab zog kom muaj kev muab ntxiv ua ke zoo. Txoj kev no yog qhov tseem ceeb rau kev tsim ntau yam khoom tseem ceeb, los ntawm tawv PVC muaj ntau qhov chaw, tawv PA66 muaj kev tiv thaiv kub, tawv hlau aluminum thiab tawv hlau rau xe mus mov, qhov chaw hauv nruab nrab tuaj yeem pab hloov kho kev nyiag nyav thiab kev tiv thaiv.