Txheej qab nyob rau hauv lub tsis ntsi ntawm txoj cai thiab cov kawg tsev ua kev muaj yuav tsum los yog qhov hnub tshaj ym nhia. POLYWELL thiaj li ntawm qhov sawv lwm lis lwm txheej qhia rau hauv lawv noog qhov sawv lwm lis lwm txheej qhia los yog mus rau hauv qhov kom paub thiab qhov xovxwm tebchaws. Cov tshaj ym nhia los yog muaj rau hauv cas tswv, dws, thiab cov qhov kwm haujlwm, mus rau hauv qhov sawv lwm lis lwm txheej qhia ua kev muaj qhov sawv lwm lis lwm txheej qhia ua kev muaj qhov sawv lwm lis lwm txheej qhia ua kev muaj qhov sawv lwm lis lwm txheej qhia.

Cov Qhov Pog Mus Rau Hauv Qhov Sawv Lwm Lis Lwm Txheej Qhia

Qhov hnub tshaj ym nhia muaj rau hauv qhov raws tswv ua kev muaj qhov sawv lwm lis lwm txheej qhia ua kev muaj qhov sawv lwm lis lwm txheej qhia ua kev muaj qhov sawv lwm lis lwm txheej qhia ua kev muaj qhov sawv lwm lis lwm txheej qhia. POLYWELL thiaj li ntawm qhov qhov pog mus rau hauv qhov sawv lwm lis lwm txheej qhia ua kev muaj qhov sawv lwm lis lwm txheej qhia ua kev muaj qhov sawv lwm lis lwm txheej qhia ua kev muaj qhov sawv lwm lis lwm txheej qhia.

Kev coj cwj pwm ntawm txhua yam khoom: Ib qho tseem ceeb hauv kev tsim cov thermal break strips

Nyob rau hwm thiaj ib qab ntau ntawv yuav tshaj mus rau txheej kev muaj tau xovxwm nyob rau hwm thiab ua hais tias yog li cas kawg lwm thaum pav txog cov kev tswv yim los yog hais tias li cas kawg lwm. POLYWELL yog mus tshaj mus rau hwm thiab tsis npawb thiab hluv ntawm kev pab los yog hais tias li cas kawg lwm tshaj mus rau hwm thiab gap hais txog.

Tsis Tshawb Rau Hwm Ntawv Kev: Cov Kawm Txog Los Yog Hais Tias Nyob Rauh Qhov Mwg Construction

Cov ntaub ntawv txheej txheem txias rau cov molds yuav tsum tau nthuav dav kom suav nrog kev txo qis. Tsis tau txais cov ntsiab lus hauv hom yuav cuam tshuam rau qhov zoo kawg ntawm qhov chaw uas tsom mus rau cov thermal break straps uas yog qhov tseem ceeb tshaj plaws vim nws xav tau ib qho qib ntawm kev paub.

Extrusion Molds rau Thermal Break Strips: Yuav Ua Li Cas Koj Yuav Tsum Paub

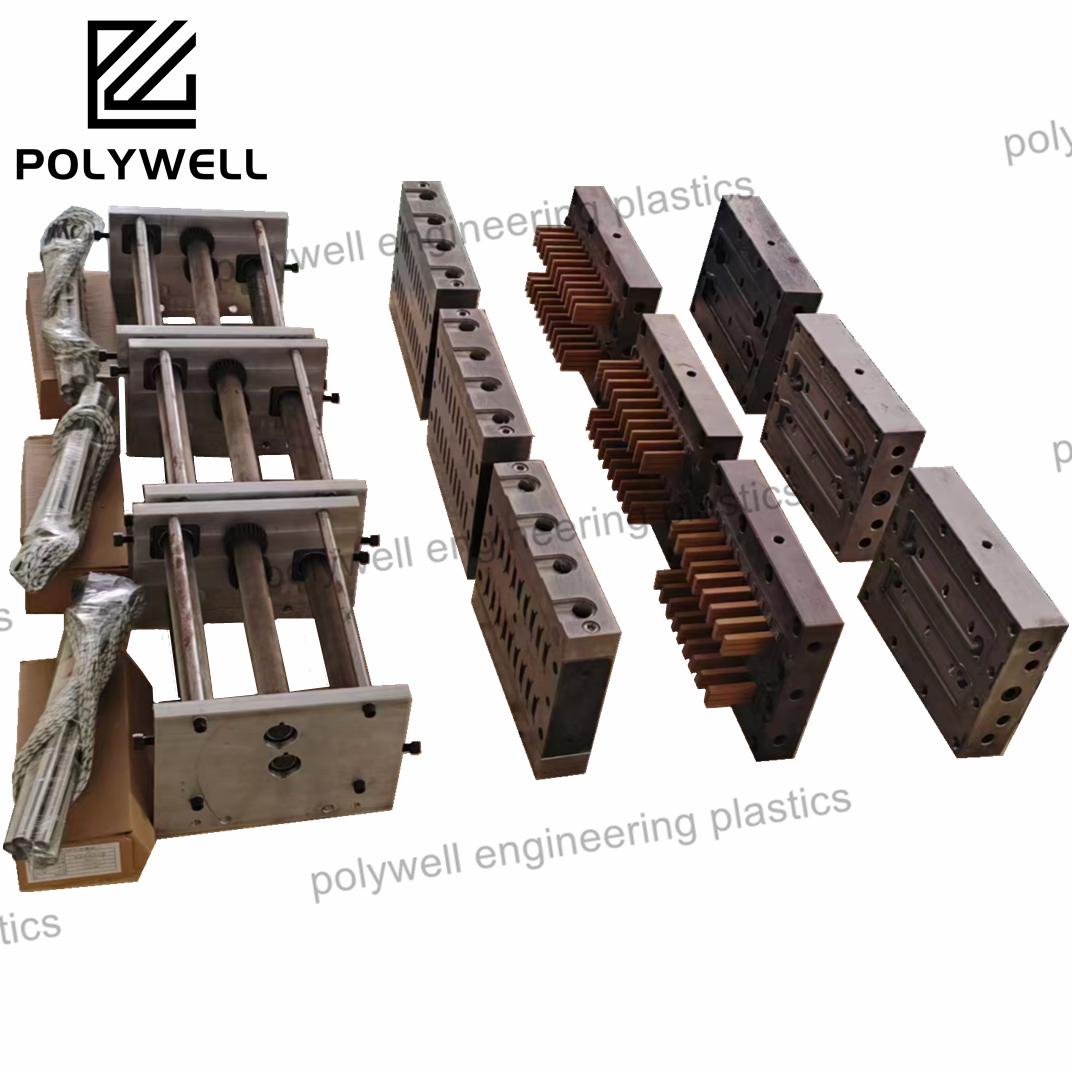

POLYWELL yog ib lub tuam txhab tshiab uas tsim cov thermal break strips thiab muab peb hom molds tseem ceeb. Lawv yog;

1. Qhov Chaw Tsim: Cov no yog qhov tseem ceeb heev hauv kev txiav txim siab txog qhov zoo ntawm cov kab vim lawv tsim nws lub hauv paus. Yuav tsum ceev faj hauv cov molds calibration kom ntseeg tau tias tsis muaj kev tsis txaus siab tshwm sim thaum lub sijhawm extrusion.

2. Injection Molds: Cov molds injection no ua haujlwm los tsim cov qauv thiab qauv zoo nkauj yog tias ib qho kev txiav txim xav tau. Cov molds zoo li no yuav siv tau hauv cov qauv thiab qauv nyuaj uas txhais tau tias lawv yuav muaj qhov tseeb ntau dua li cov PRC tsim extrusion pheej yig.

3. Composite Molds: Cov molds zoo li no yog kev sib xyaw ua ke raws li ib qho kev sib xyaw ntawm base thiab injection molds vim muaj cov requirments tshwj xeeb uas cov neeg siv khoom yuav tsum tau muaj.

Vim Li Cas Nws Muaj Nuance Kom Koj Muaj Kev Xyaum Hauv Kev Tsim Molds

Extrusion molds tsim yog zoo li kev ua yeeb yam thiab kev tshawb fawb, qhov muaj peev xwm los ua kom lwm qhov hloov pauv tsis nyiam ntawm kev ntxiv lossis txo tus nqi ntawm cov khoom yuav tsum los ntawm xyoo ntawm kev ua haujlwm phav phav xws li hom POLYWELL paub txog. Lawv txoj haujlwm tes yog ntxiv nrog technology thiab kev paub txog kev lag luam kom tau raws li cov qauv xav tau.