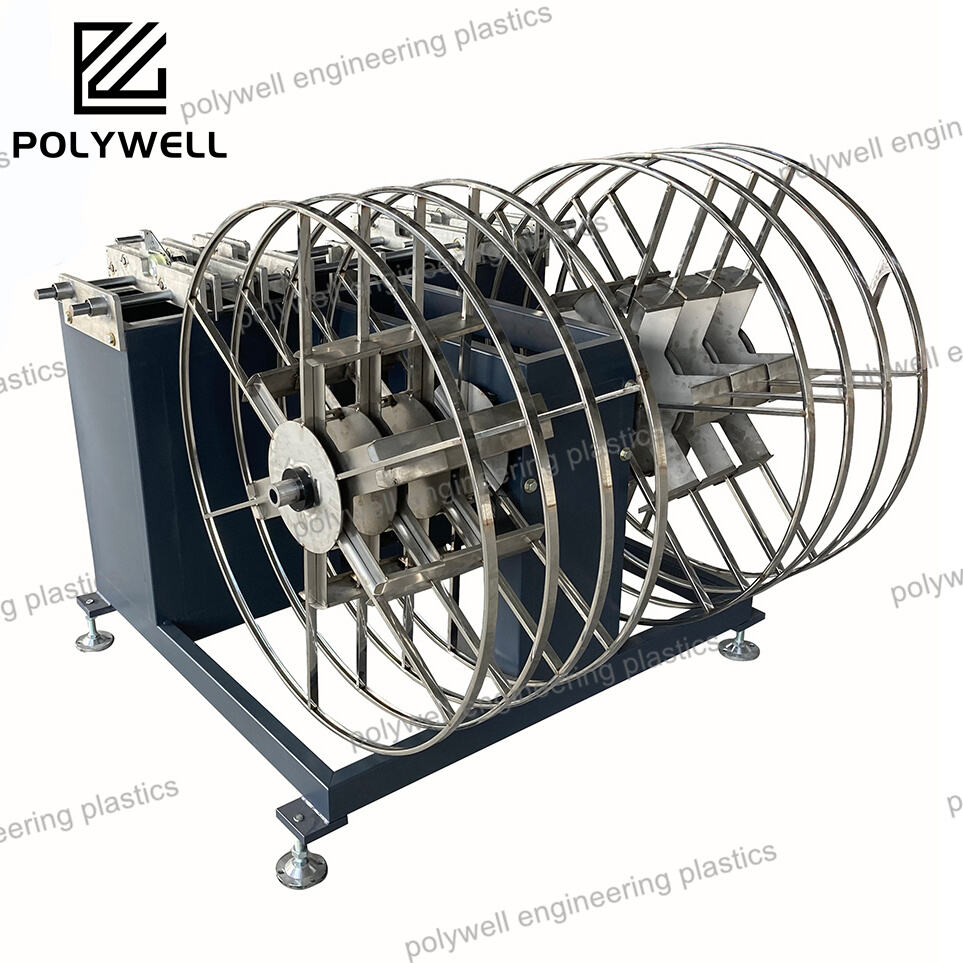

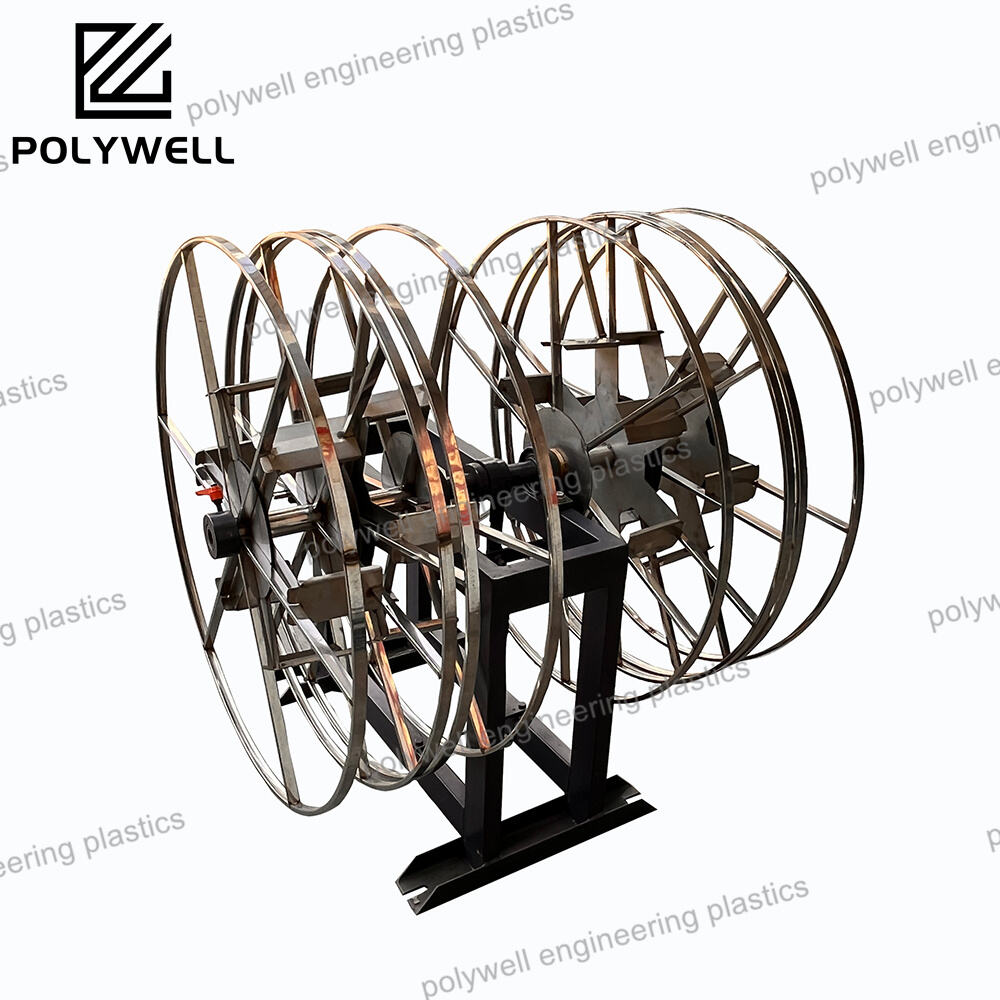

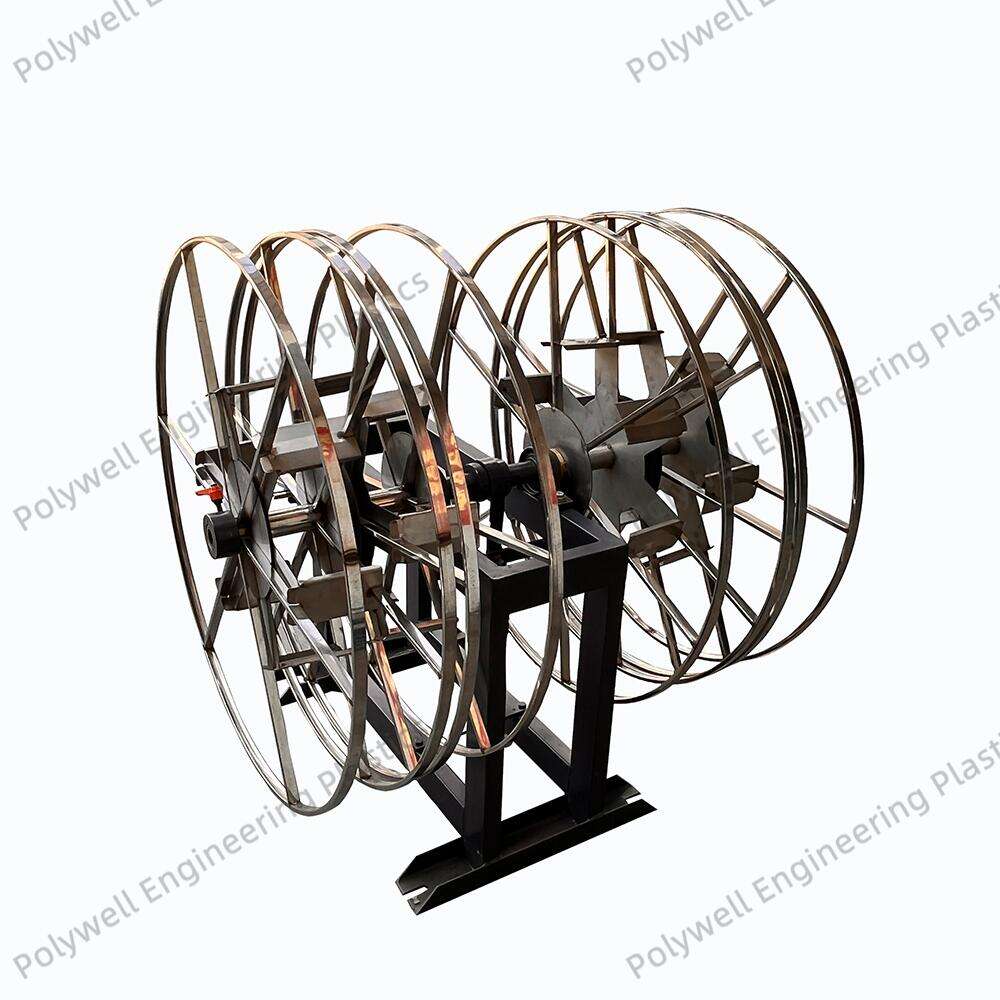

En profilomviklingsmaskine er en specialiseret type emballageudstyr, der er designet til at påføre en beskyttende omløbning omkring lange, kontinuerlige ekstruderede profiler. Selvom det nogle gange bruges til at beskrive maskiner, der påfører dekorative vinylfolier på stive profiler som PVC-vinduesrammer, refererer det typisk i en emballagekontekst til et system, der vikler fleksible opspulede profiler. Denne proces er afgørende for at beskytte sårbare overflader mod ridser, støv og fugt under lagring og transport. Maskinen fungerer ved at føre en spole fra en opspuler ind i en omløbningsstation, hvor en folie – typisk strækfolie eller en forudstrakt polyethylenfolie – vikles spiralkonformt omkring spolens omkreds. Nøglen til en effektiv omløbning er konstant foliespænding og overlap, hvilket skaber et tæt og sikkert bundt uden at komprimere og beskadige profilen indeni. Mere avancerede versioner af denne maskine kan bruge krympefolie, hvor den omviklede spole derefter passerer igennem en varmetunnel, hvilket får folien til at trække sig tæt sammen omkring produktet og derved danne en robust, tyverisikret og vejrfast forsegling. Disse maskiner er højt automatiserede og udstyres ofte med PLC'er til indstilling af antal omløb, foliespænding og rotationshastighed. De kan også inkludere integrerede folieafledere og -skærere. Fordele ved at implementere en profilomviklingsmaskine er mange. Den øger markant produktbeskyttelsen i forhold til manuel omløbning og reducerer spild samt omkostninger forbundet med beskadigede varer. Den forbedrer emballagens ensartethed og præsentation, øger gennemløbet på emballagelinjen og kan reducere materialeforbruget gennem optimeret foliestyring. For producenter, der leverer til krævende industrier som bilindustrien eller byggebranchen, er denne maskine en afgørende investering i kvalitetssikring, der sikrer, at produkter såsom gummiforseglinger eller polymeriske varmebrydere ankommer til deres destination i fejlfri, fabriksgammel stand.