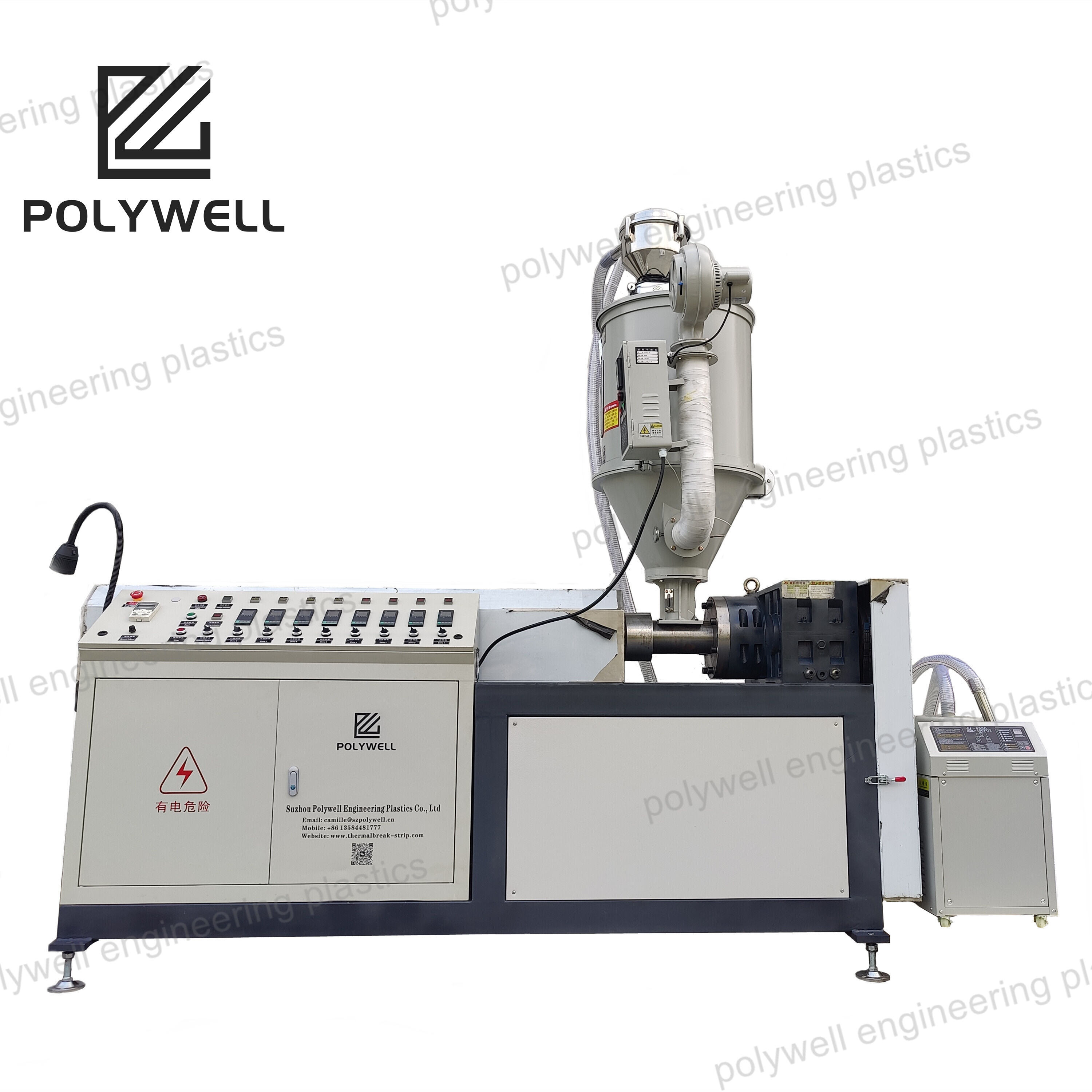

The technological distinction between single screw and twin screw extruders represents one of the fundamental divisions in polymer processing equipment, with each platform offering distinct advantages tailored to specific applications. Single screw extruders operate on relatively simple mechanical principles where friction between the rotating screw and stationary barrel conveys material forward while generating heat through viscous dissipation. This straightforward approach results in robust, cost-effective machines suitable for continuous processing of pre-compounded materials in applications like pipe extrusion, sheet production, and fiber spinning. Their limitations include restricted mixing capability, sensitivity to material flow properties, and limited devolatilization effectiveness. In contrast, twin screw extruders, particularly co-rotating intermeshing designs, provide positive displacement conveying, modular construction allowing precise customization of screw configuration, and intense mixing through specialized kneading blocks. These characteristics make them indispensable for compounding operations incorporating fillers, reinforcements, or multiple polymer phases, reactive extrusion processes, and devolatilization of volatile components. Process control considerations differ significantly, with single screw extruders requiring careful balancing of thermal profiles and screw design for stability, while twin screw extruders offer extensive manipulation of mixing intensity, residence time, and energy input through screw configuration changes. Operational economics favor single screw extruders for capital cost and maintenance simplicity, while twin screw systems provide value through process flexibility and formulation capabilities. Recent convergence has seen single screw designs incorporating more sophisticated mixing sections, while twin screw manufacturers develop cost-optimized versions for specific markets. The selection process must evaluate material characteristics, product specifications, production volume, and future flexibility requirements, with many operations utilizing both technologies in complementary roles within their production ecosystem. Understanding the fundamental operating principles and capability boundaries of each technology enables optimal equipment selection matching machine capabilities to specific process requirements.