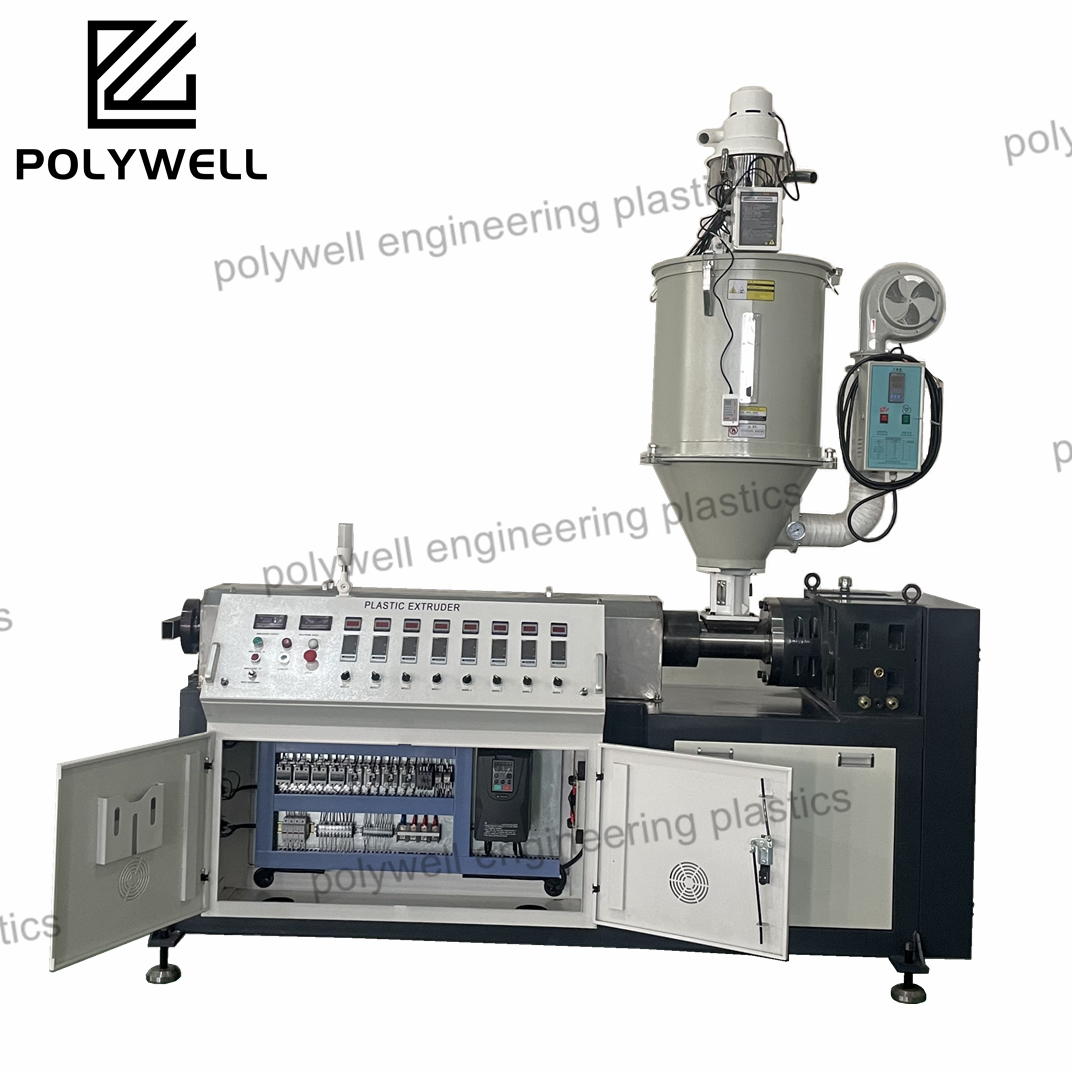

High-tech machinery is needed to produce thermal break strips that serve as a component of energy-efficient doors and window systems. Among them is the POLYWELL Single Screw Extruder, confidently designed to cater to the thermal break tape extrusion process.

POLYWELL Single Screw Extruder Features

POLYWELL Single Screw Extruder is a complex combination of advanced technology and innovative techniques developed for thermal break tape machines. Its attributes include:

Ultimate Control System: Having control systems in the form of PLC’s the extruder maintains the temperature and speed requisites for ensuring a good quality thermal break strip.

Resilient Structure: Constructed of high quality materials that can endure a high working load hence requiring less maintenance and lasting longer.

Screw Design Precision: Utilizing single screws that allow the free-flow of polymer blends used in thermal break strips, the extruder ensures that the resultant product is fluid and of mix all the necessary components .

Low Energy and Cost: Reduced running expenses due to the addition of cost-efficient aids while still maintaining a reasonable output rate.

Complete Custom Glove Service: Aiming for production purposes, POLYWELL Single Screw Extruder can be adjusted from material nature to the properties needed post-production.

Benefits of Employing POLYWELL’s Single Screw Extruder

For those in the manufacturing sector and are looking to advance their production processes, the POLYWELL Single Screw Extruder would be more than sufficient as it comes with a number of listed advantages:

Enhanced Quality: Accurate control over the extrusion process enables manufacturers to produce thermal break strips of high quality with minimal effort.

Faster Production: Great output and minimized downtime can culminate in cost reductions while simultaneously maximizing the profit.

Wider Applicability: Mostly, the PA66 polymer that is used in thermal break strips is reinforced with glass fibers which augment thermal break polymer’s utility.

Ease of Use: Minimal maintenance and operator attunement is required due to the use of easy to understand and use controls and components to facilitate the process.

Environmental Friendly: Reducing energy utilization and waste generation complements the goal of the eco manufacturing process.

Notes on Production of Thermal Break Strip

Breaking the thermal bridge helps in cutting down energy expenditure on windows, doors and curtain wall systems. With the use of single screw extruder from POLYWELL, the manufacturers can:

Generate High Quality Strips: The bonds that exist between aluminum profiles can be used to make strips, these strips are good insulators and have a low thermal conductivity.

Strips would be always compatible: These extruder are ultra precise and produce strips of exact dimensions that can the requirements to be used in cutting edge architectural systems.

Introduce new products: Manufacturers can make a move to more elaborate customized strip designs and other dimensions thus pulling in a larger customer base.

Why POLYWELL?

POLYWELL is a first in the field of extrusion as it has the best experience and customers support available in the market. Their Single Screw Extruder is not a mere machine – it is a key to a new level of efficiency in the manufacturing of thermal break strips. POLYWELL promises to uphold the principles of quality, environmental responsibility and client satisfaction, guaranteeing that its equipment corresponds to any changes in the market.