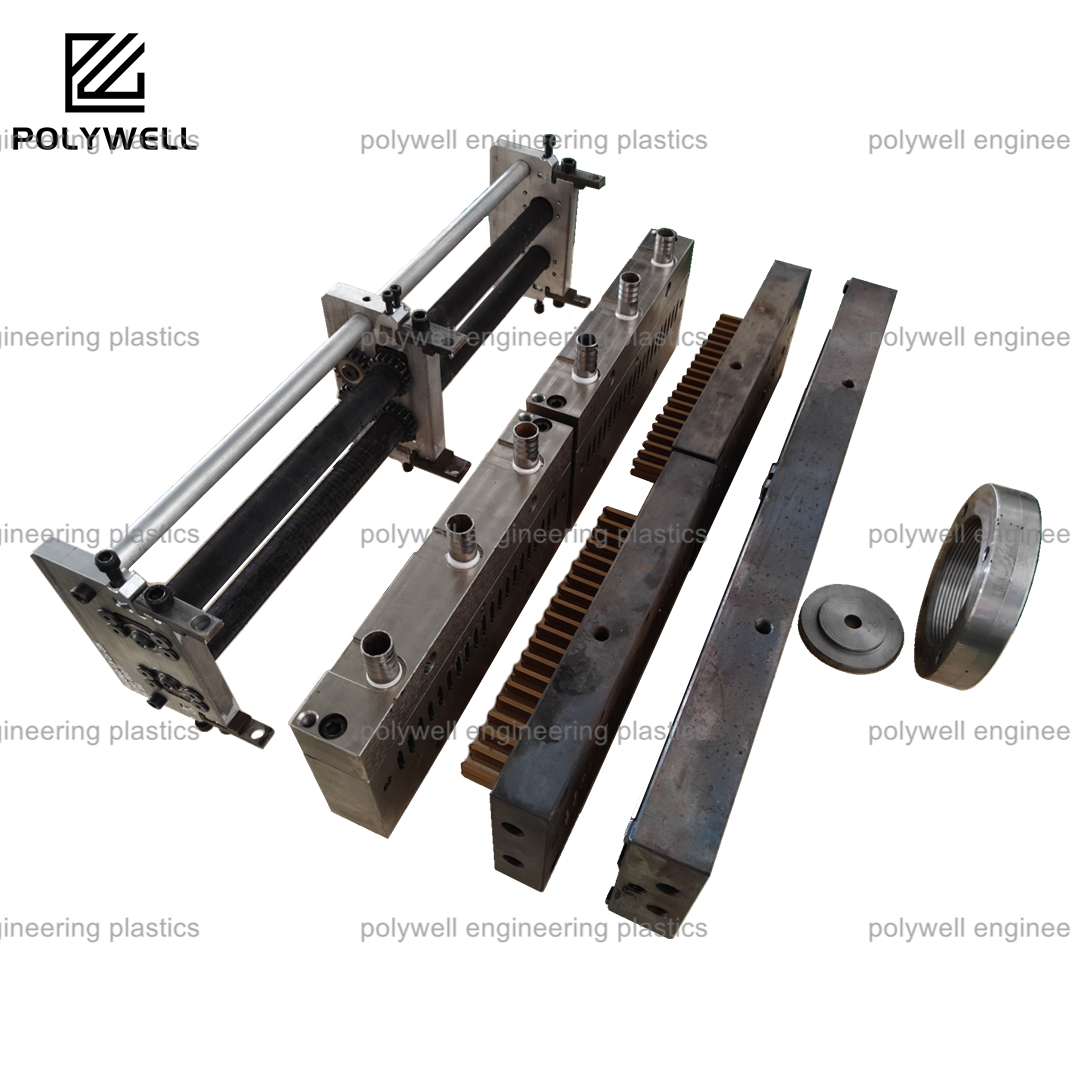

The term "PA extrusion mould" refers to the specialized tooling system, specifically the die, used in the continuous shaping of molten polyamide into a profile, tube, sheet, or filament. This tool is a critical component that defines the final geometry, surface quality, and dimensional accuracy of the extrudate. Designing and manufacturing a die for polyamide requires careful consideration of the material's specific rheological and thermal properties. A key challenge is managing the significant and often anisotropic shrinkage that occurs as the semi-crystalline PA melt cools and solidifies. The die geometry must therefore be precisely calculated to compensate for this post-die swelling (die swell) and subsequent shrinkage. The flow path within the die must be streamlined to avoid dead spots where material can stagnate, degrade, and cause black specks or gels in the product. The land length, the final parallel section of the die flow channel, is crucial for stabilizing the melt flow and ensuring consistent dimensions. Temperature control is paramount; the die is typically equipped with multiple independent heating zones and, sometimes, cooling circuits to maintain a uniform thermal profile across the melt. Wear resistance is another critical factor, especially when processing glass-filled PA grades, which are highly abrasive. Consequently, extrusion moulds for PA are often constructed from high-grade tool steels and frequently feature wear-resistant coatings or hardened inserts in critical areas. The design is a complex interplay of fluid dynamics, heat transfer, and material science, aimed at achieving a stable process and a high-quality, dimensionally stable product.