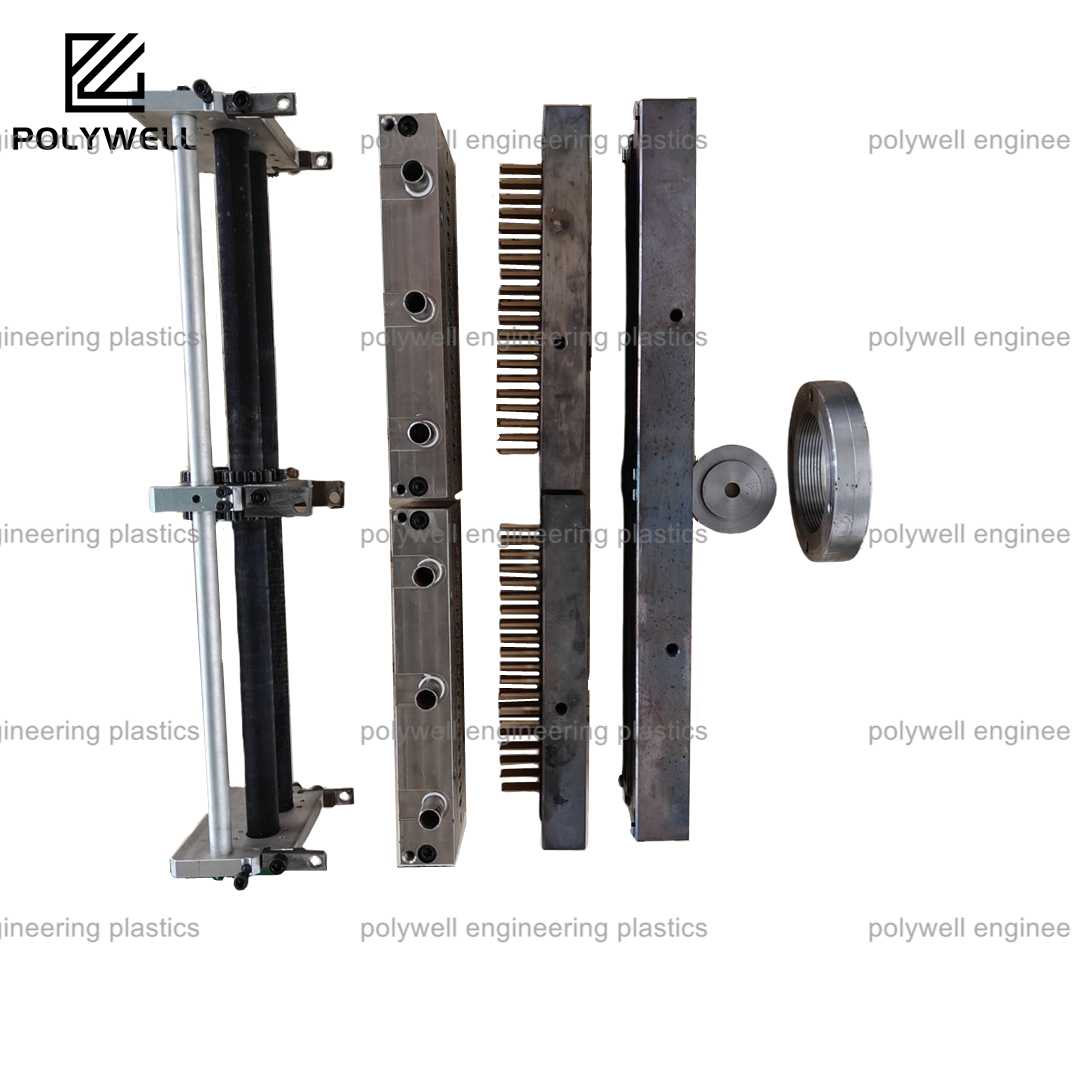

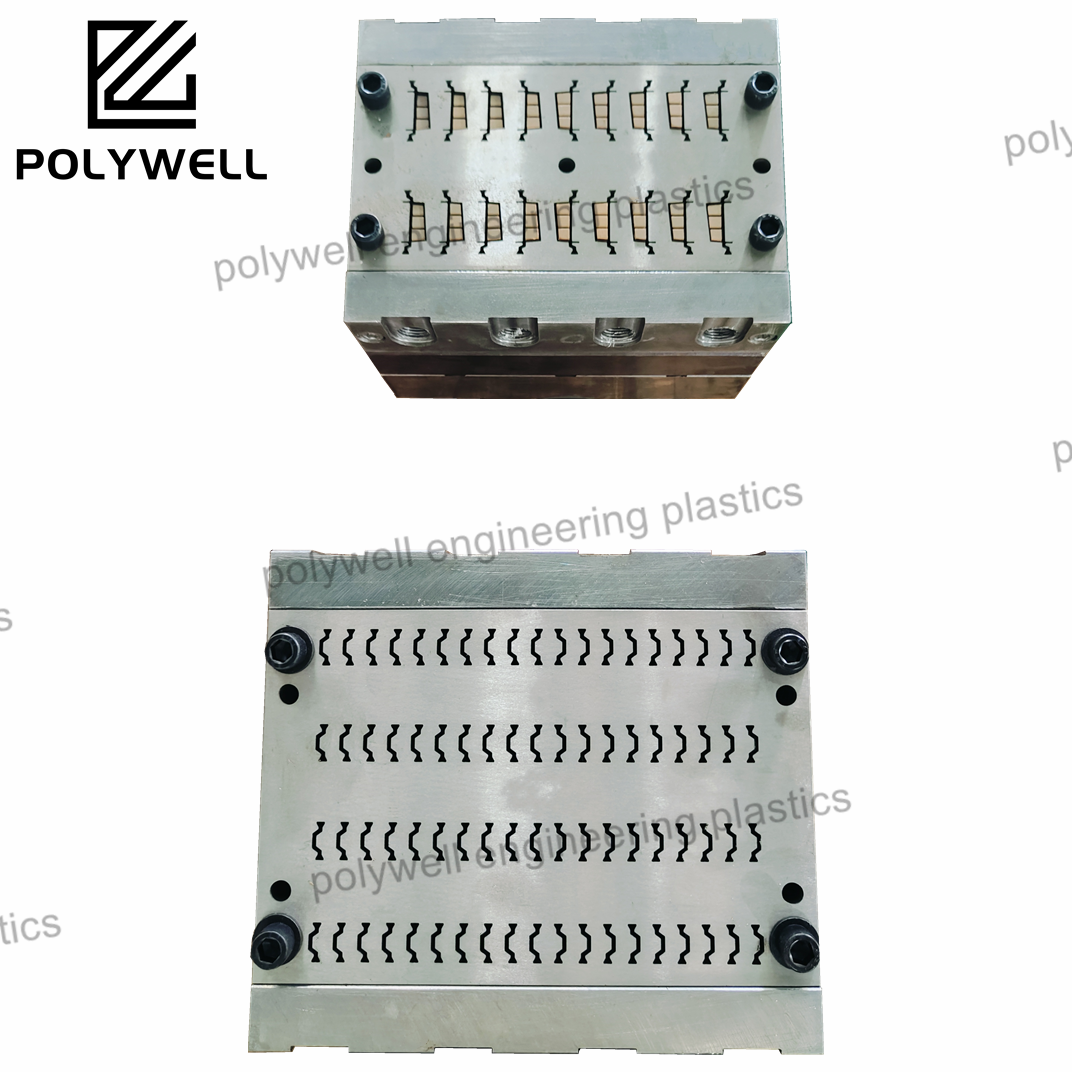

Custom plastic components represent a specialized manufacturing sector focused on producing tailored solutions for specific application requirements across diverse industries. The development process begins with comprehensive requirements analysis, identifying mechanical performance needs, environmental exposure conditions, regulatory compliance requirements, and aesthetic expectations. Material selection is a critical phase, with engineers evaluating thousands of polymer formulations and composites to identify the optimal balance of properties including strength, flexibility, heat resistance, chemical compatibility, color fastness, and cost-effectiveness. The design engineering phase translates performance requirements into manufacturable geometries, applying plastic-specific design principles such as uniform wall thickness, appropriate draft angles, and structural ribbing. Manufacturing process selection depends on production volume, part complexity, and material characteristics, with options including injection molding for high-volume production, CNC machining for prototypes and low volumes, or thermoforming for large, thin-walled components. Tooling design and fabrication represent significant upfront investment, with mold engineering optimizing gating, cooling, and ejection systems for efficient production. Quality assurance processes include first-article inspection, statistical process control, and comprehensive testing protocols validating dimensional accuracy, mechanical performance, and environmental durability. Successful custom plastic component manufacturing requires close collaboration between customer and manufacturer throughout the development process, from initial concept through production ramp-up. Advanced manufacturers offer value-added services including secondary operations (assembly, decorating, packaging) and supply chain management. The result is purpose-engineered components that deliver optimal performance in their intended application while providing economic advantages through part consolidation, weight reduction, and assembly simplification.