-

Thermal Break Strip

-

Polyamide Nylon 66

-

Glass Filled Nylon 66

-

Broken Bridge Aluminum Window

-

Plastic Moulding Dies

-

Nylon Extruder Machine

-

Single Screw Extruder

-

Pipe Production Line

-

Plastic Extrusion Machine

-

Aluminum Cutting Machine

-

Plastic Granulator Machine

-

Tensile Testing Machine

-

Laser Code Printer

-

Water Bottling Machine

-

Mr. Paolo CelaniThank you very much for very good news! We appreciate your honesty and collaboration. You have supplied good dies, all sizes within tolerance. We have ordered dies for a total amount of more than 200,000 USD and we are continuing to order. Thank you again to you and your very professional team.

Mr. Paolo CelaniThank you very much for very good news! We appreciate your honesty and collaboration. You have supplied good dies, all sizes within tolerance. We have ordered dies for a total amount of more than 200,000 USD and we are continuing to order. Thank you again to you and your very professional team. -

Mr. Martyn HainesThank you for your help with this order and if ever you need someone to tell customers how helpful you are just tell them to contact me.

Mr. Martyn HainesThank you for your help with this order and if ever you need someone to tell customers how helpful you are just tell them to contact me. -

Mr. Dietmar DürrI received your samples. I agree to Mr. Wölki, they looks pretty good. We will arrange the balance payment. Please pack the mold and send them asap.

Mr. Dietmar DürrI received your samples. I agree to Mr. Wölki, they looks pretty good. We will arrange the balance payment. Please pack the mold and send them asap.

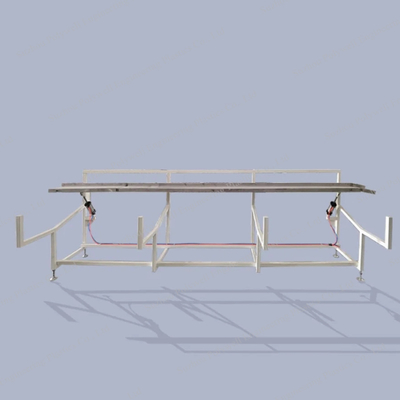

PVC Door Frame Window Profile Extrusion Production Line Plastic Wood WPC PVC Window Door Frame Making Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Delivery Time | 30-60 Days | Production Capacity | 100 Set /Year |

|---|---|---|---|

| Screw | Double-Screw | Feeding Mode | Automatic Feeding |

| Main Electrics | Siemens Or Schneider | Inverter | ABB |

| Voltage | 380V 50Hz 3pH Or Customized | After-sales Service Provided | Engineers Available To Service Machinery Overseas |

| High Light | PVC Plastic Profile Extrusion Production Line,Schneider PVC Profile Extrusion Line,WPC PVC Window Door Frame Extrusion Line |

||

PVC Door Frame Profile Extrusion Production Line China Stable Extrusion Plastic Wood WPC PVC Window Door Frame Profile Panel Making Machine Factory

Production Introduction

The production line is mainly based on various kinds of PVC as raw materials, extrude raw materials with a twin screw extruder, equipped with different sizes and shapes of molds, match with a corresponding calibrating table or cooling tank, hauling machine, cutting machine, and rack, can produce a variety of different plastic profiles. We can customize the production line according to customer samples.

This product can be used on skirting panel profile for ceiling, wall panel, background wall, window frame, door frame, skirting board, elevator door frame, etc. special for public and private decoration, such as villa, house, hotel, shopping mall, etc.

It's mainly used to produce PVC / WPC wall panel, PVC window & door profile, PVC ceiling tile, PVC skirting etc.

It is a kind of high efficiency equipment for plastic extrusion, it is mainly composed by force feeder, soft plasticization screw and barrel, high precision gearbox, exhaust system, it is features of even mixing, better plasticization,stable working, high capacity, and it is suitable for produce PVC products from mixed powder, within different mold and other auxiliary equipments, it can produce plastic pipe, profile, board, sheet, granules, etc.

![]()

![]()

Properties and advantages

This line features stable plasticity, high output, low sheering force, long life service, and other advantages. The production line consists of the control system, conical twin-screw extruder, calibration unit, haul-off unit, cutter, film covering machine, and stacked, the extruder is equipped with an advanced AC inverter, imported temperature controller(RKC/OMRON). the calibration unit's vacuum pump and haul-off unit's motors are famous brand products. after a simple changing of the die and screw, it also can produce the foam profiles.

Work flow and detailed information

|

![]()

Equipment Usage Environment

Equipment usage environment

Power supply: AC380V, 50Hz, three-phase or customized.

Cooling Water hose/pipe: ≤20℃, ≥0.3Mpa, ~4 M3/hr

Ambient temperature: -10ºC-+42ºC

Relative humidity: 40%~90%

Compressed air: working pressure is 0.4 ~ 0.6MPa

Manpower:2 peoples

Main Machine Parts

| NO. | Specification | Quantity |

| 1 | Double-screw extruder with Automatic loading system | 1 set |

| 2 | Die head | 1 set |

| 3 | Calibrating and cooling device | 1 set |

| 4 | Haul-off machine | 1 set |

| 5 | Cutting machine | 1 set |

| 6 | Stacker | 1 set |

The services We Can Provide

1. We can provide factory building construction and renovation plan, pipe laying plan in the factory building, circulating cooling pool construction plan, etc.

2. Provide purchasing plans for raw materials, transformers, air compressors, etc.

3. Provide specific formulas of relevant raw materials, excellent raw material suppliers, raw material cost accounting, etc.

4. Provide install equipment, debug equipment, train employees, and provide technical support all year round, etc.

5. We a nationwide plastics industry engineer alliance. If distance permits, we can provide relevant talents to work in your company all year round as technical support.

![]()

FAQ

1. Q: Where is your loading port?

A: Shanghai Port

2. Q: Payment term:

A: T/T, Western Union or cash, etc.

3. Q: Do you have other services for your products?

A: We have rich experience in manufacturing plastic machinery, so we can manufacture various machines according to customers' requirements.

4. Q: How do you quote for customers?

A: The price depends on the quality and performance, but customer satisfaction is the first priority.

5. Q: How many engineers are there?

A: We have 10 professional engineers working and they all have passports.

6. Q: What if the machine is started before delivery? Is it free or do we need to pay?

A: Of course, we have to start the machine for you to check until you are satisfied with our machine and it is free.

7. Q: What is your warranty terms

A: Warranty period: 12 months

Seller shall grant: services and spare parts, free-of-charge service throughout the entire equipment during warranty period.

Long life service: the seller should provide long life service for the sold goods, the buyer pay for needed spare parts after the 12months warranty terms.

8. Q: What is your overseas service?

A: We will provide high quality overseas service ,our technical staff will be able to provide you with technical support, for you personally to overseas assembly and test equipment.