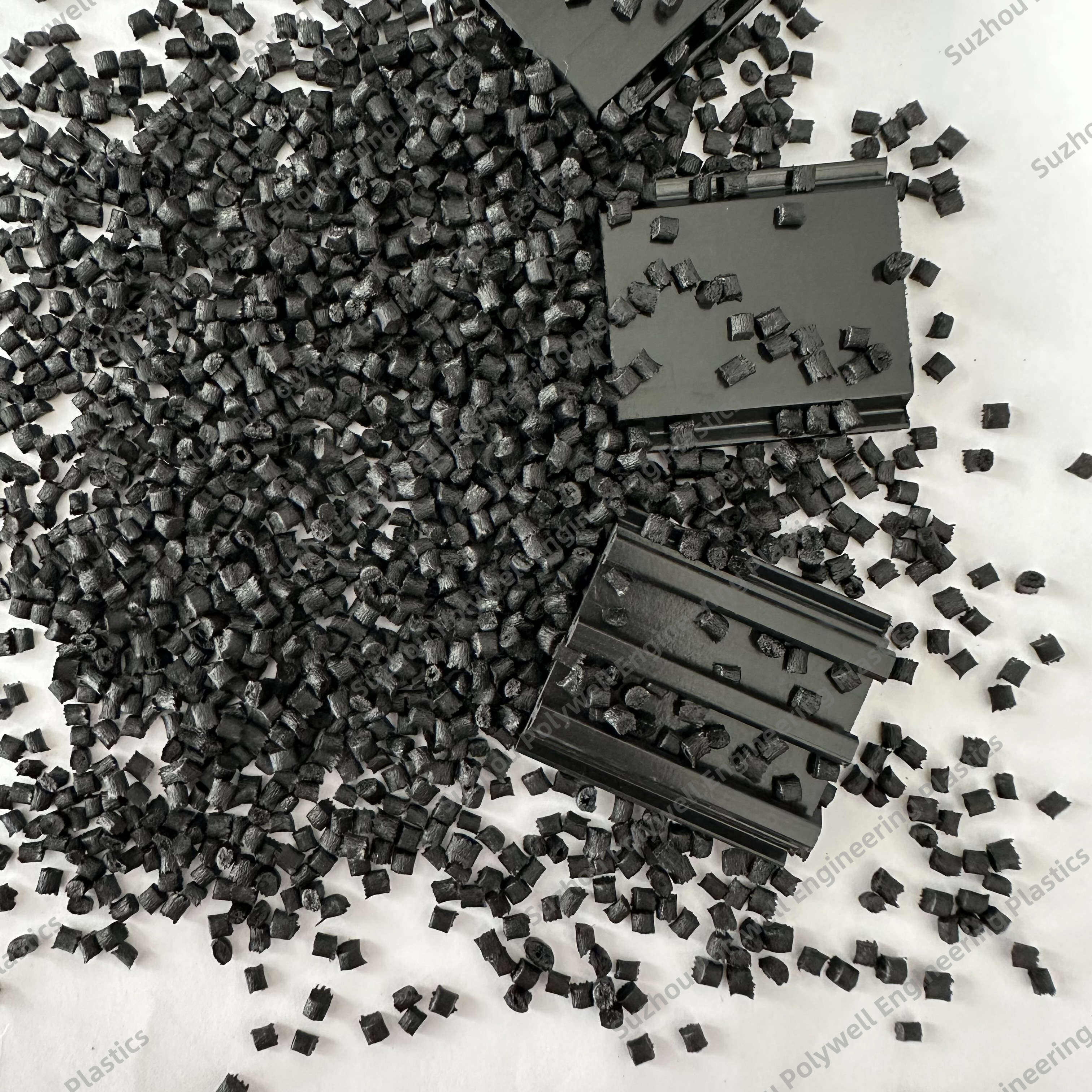

PA66 Material with Glass Fiber 25% Reinforced Modification Plastic Granules Extruding Nylon Pellets

Chain Gudie Material Nylon Rail Guide Material Runway Guide Material

- Overview

- Recommended Products

- Sample water content less than 0.2% by weight.

- Norm laboratory condition:(23±2)ºC and (50±10)% relative humidity.

- The specifications marked with "a" only applies to I-shape strip otherwise, the specifications concluded between supplier and buyer through consultation, shall be written in contract or purchase order.

Product Description:

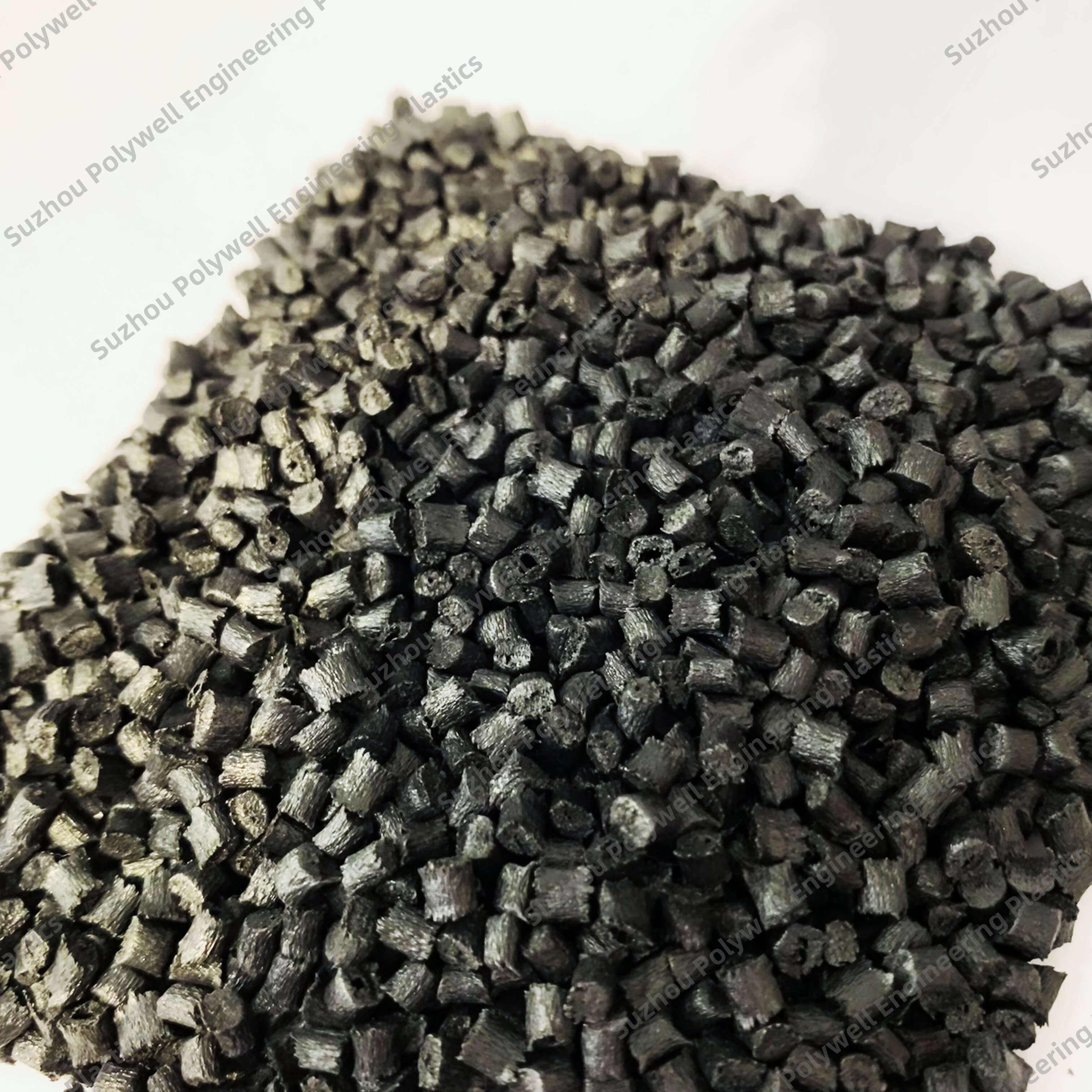

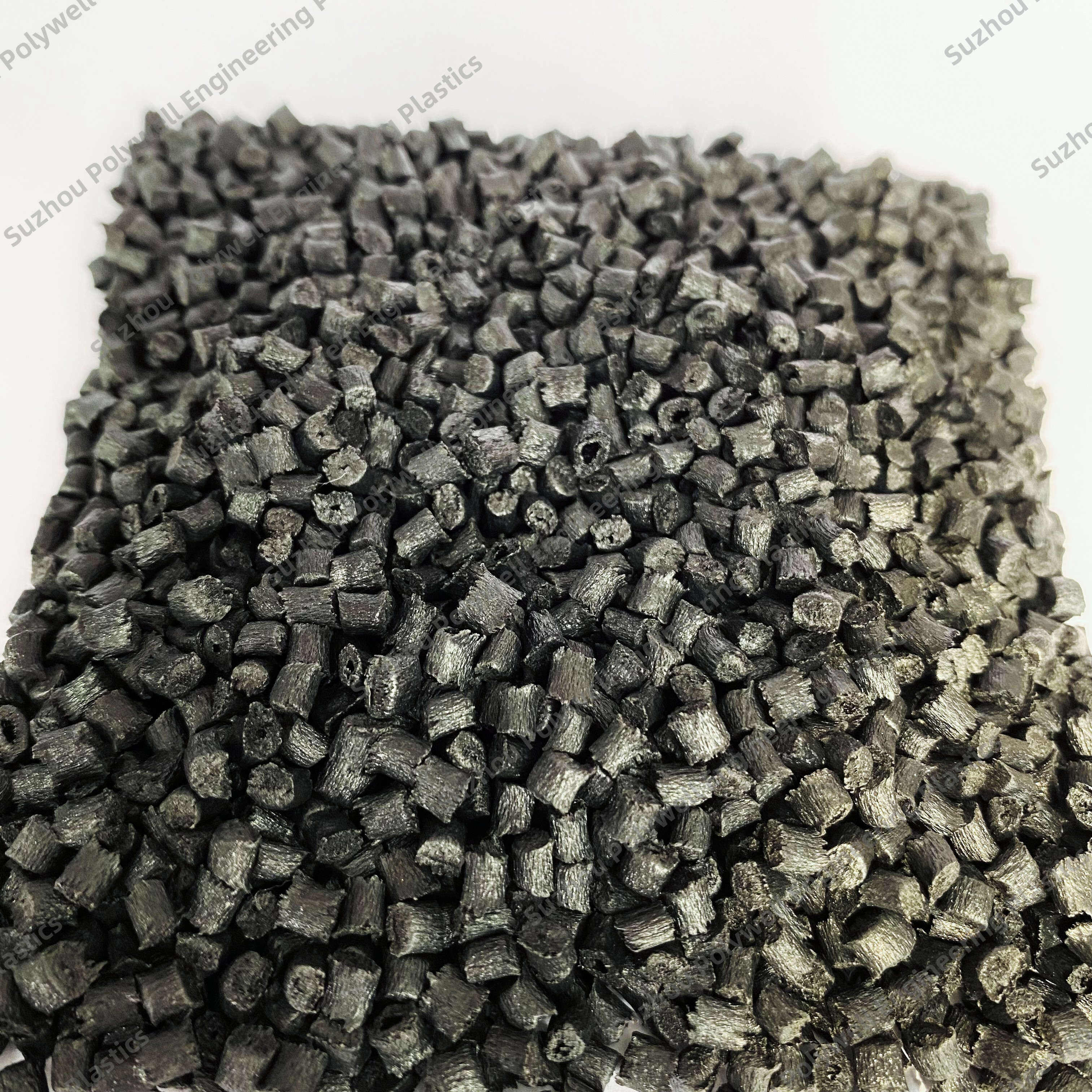

Glass fiber reinforced PA 6.6 granules with heat aging resistance extrusion moulding grade. It's good raw material for thermal break profiles of high stiffness and dimensional stability.

PA66GF25 granules are reinforced by fiberglass. The final product performance of this raw material can meet the national standard.

PA66GF25 granules are based on PA66 resin. Then the granules are formed by twin-screw extrusion machine after adding fiberglass, efficient flame retardants and various additives.

PA has the advantages of high mechanical strength, high softening point, good wear resistance, self-lubrication, cushioning, sound deadening, excellent oil and chemical corrosion resistance, and good electrical insulation. Because of these superior performance, PA composite have already replaced some metals being as structural materials.

PA66 Features

1. It has excellent mechanical properties, high strength, high toughness.

2. The material has excellent coloring ability, can achieve various requirements of color matching

3. The shrinkage rate of PA66 is between 1% and 2%. The addition of glass fiber additives can reduce the shrinkage rate to 0.2%~1%. The shrinkage ratio is large in the flow direction and in the direction perpendicular to the flow direction.

4. PA66 is resistant to many solvents, but is less resistant to acids and other chlorinating agents.

5. PA66 excellent flame retardant performance, by adding different flame retardants can achieve different levels of flame retardant effect.

What is GF in plastic material?

Glass-filled nylon is a synthetic polyamide thermoplastic and it's one of the most important materials used in engineering thanks to its strength and heat resistance. It's made by adding powdered glass to nylon resin or by extruding the plastic with glass fibers.

What is raw material for polyamide thermal break strips?

Polyamides are among the most important and proven technical thermoplastics, known for their heat resistance, stiffness and high mechanical stability.

Polyamides can be classified into different types, with PA 6, PA 6.6 and PA 12 most established on the market. Alongside ABS and PP compounds they are among the most widely used plastics, found across several sectors including the automotive, mechanical engineering, structural and installation engineering, photovoltaics and electrical engineering industries.

Glass fiber is a material consisting of numerous extremely fine fibers of glass.

Glass fibres are used as reinforcement of polymers in various fields such as aerospace, automobile, marine, sporting and leisure goods, and construction and civil engineering. One of the principal advantages of using glass fibres for reinforcement of polymers is their high performance per cost ratio.

Our company use PA 6.6 and glass fiber to produce PA66GF25 granules, which is the most suitable raw material for polyamide thermal break strips production.

Advantages of our PA6.6-gf25 granules:

Our company has devoted more than ten years to the research and development and production of nylon extruding profiles. According to customer reaction, using our PA66 granules for production can get high yield, easy start-up, and get less scrap in the early start-up stage. There will be no lack or incomplete of profiles in the production process, thus avoiding material waste, saving customer costs and improving production efficiency.

About color:

The color of our PA66GF25 granules is black, but we also can customize according to customers’ requirements.

Application:

Specially used in thermal break strips, thermal bridge, heat insulation bar, etc.

Package and Delivery:

Packaging details |

25 kg/bag |

Lead time |

10-15 working days |

Delivery details |

10-16 tons per 20 feet container 20-25 tons per 40 feet container |

FAQ:

Q: About Sample

A: Sample is Free, but the express fee is collect. Customer can also choose their own cooperated courier company.

Q: About MOQ

A: For the polyamide granules, MOQ is 1 ton. For the thermal break strips, MOQ is 5,000 meters.

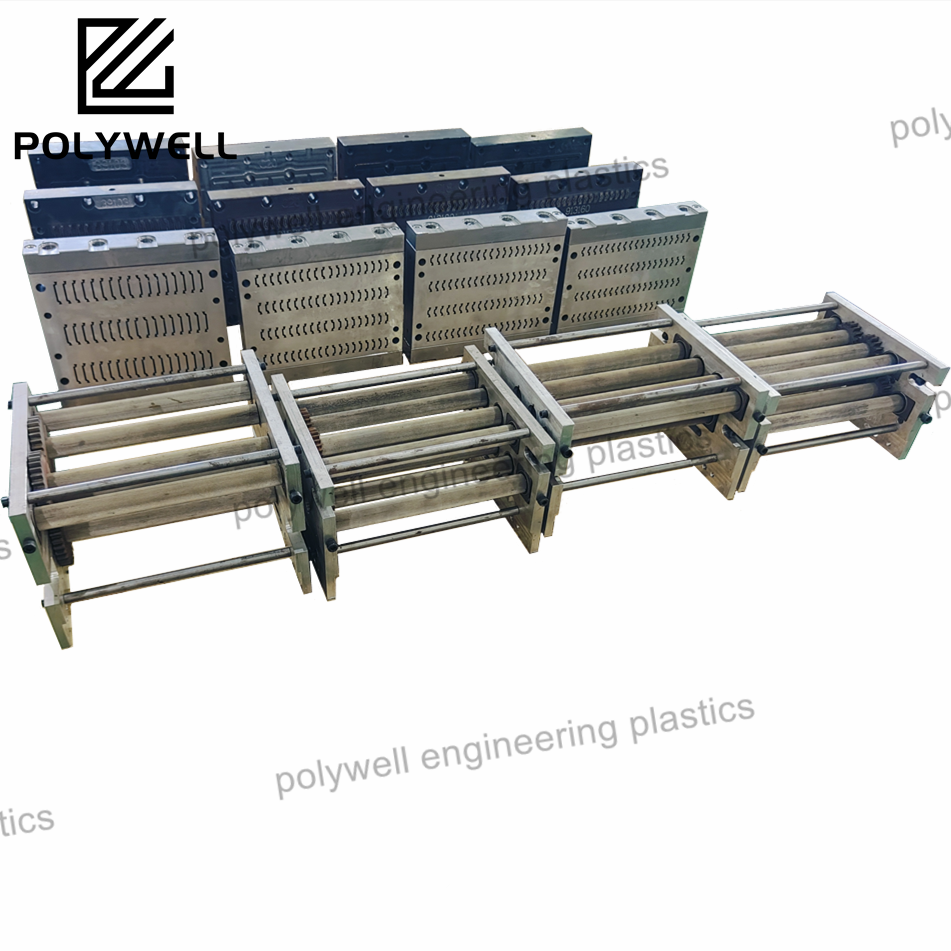

Q: About Customizing Special Shape Of Polyamide Profiles And Its Period

A: You can customize the special shape of polyamide strips. If we didn't meet this shape before, we will make new mold for you, and customer needs to pay for the mold.

Q: About Customizing Package Style and Marks

A: You can customize the package style and marks.

Q: Why your price is higher/lower than others?

A: For years specializing in polyamide granules and thermal break strips has bestowed us experienced and skilled technical workers and production workers. We promise the stability of products and the high-quality of raw material. Furthermore, we can provide technical support from raw material to the final appliance.

Q: About warranty

A: 1 year. We are confident in our products, and pack them well before delivery, so usually you will receive your order in good condition. Any quality issue, we will deal with it immediately.

Q: About Payment or other question

A: 50% T/T deposit before production, 50% T/T balance before loading.

Product Performance

Item |

Unit |

GB/T 23615.1-2009 |

PW-Technical specification |

Density |

g/cm3 |

1.3±0.05 |

1.28-1.35 |

Linear expansion coefficient |

K-1 |

(2.3-3.5)×10-5 |

(2.3-3.5)×10-5 |

Vicat softening temperature |

ºC |

≥230 |

≥233 |

Melting point |

ºC |

≥240 |

≥240 |

Testing for tensile cracks |

- |

No cracks |

No cracks |

Shore hardness |

- |

80±5 |

77-85 |

Impact strength(Unnotched) |

KJ/m2 |

≥35 |

≥38 |

Tensile strength(longitudinal) |

MPa |

≥80a |

≥82a |

Elasticity modulus |

MPa |

≥4500 |

≥4550 |

Elongation at break |

% |

≥2.5 |

≥2.6 |

Tensile strength(transverse) |

MPa |

≥70a |

≥70a |

High temperature tensile strength(transverse) |

MPa |

≥45a |

≥47a |

Low temperature tensile strength(transverse) |

MPa |

≥80a |

≥81a |

Water resistance tensile strength(transverse) |

MPa |

≥35a |

≥35a |

Aging resistance tensile strength(transverse) |

MPa |

≥50a |

≥50a |

EN

EN