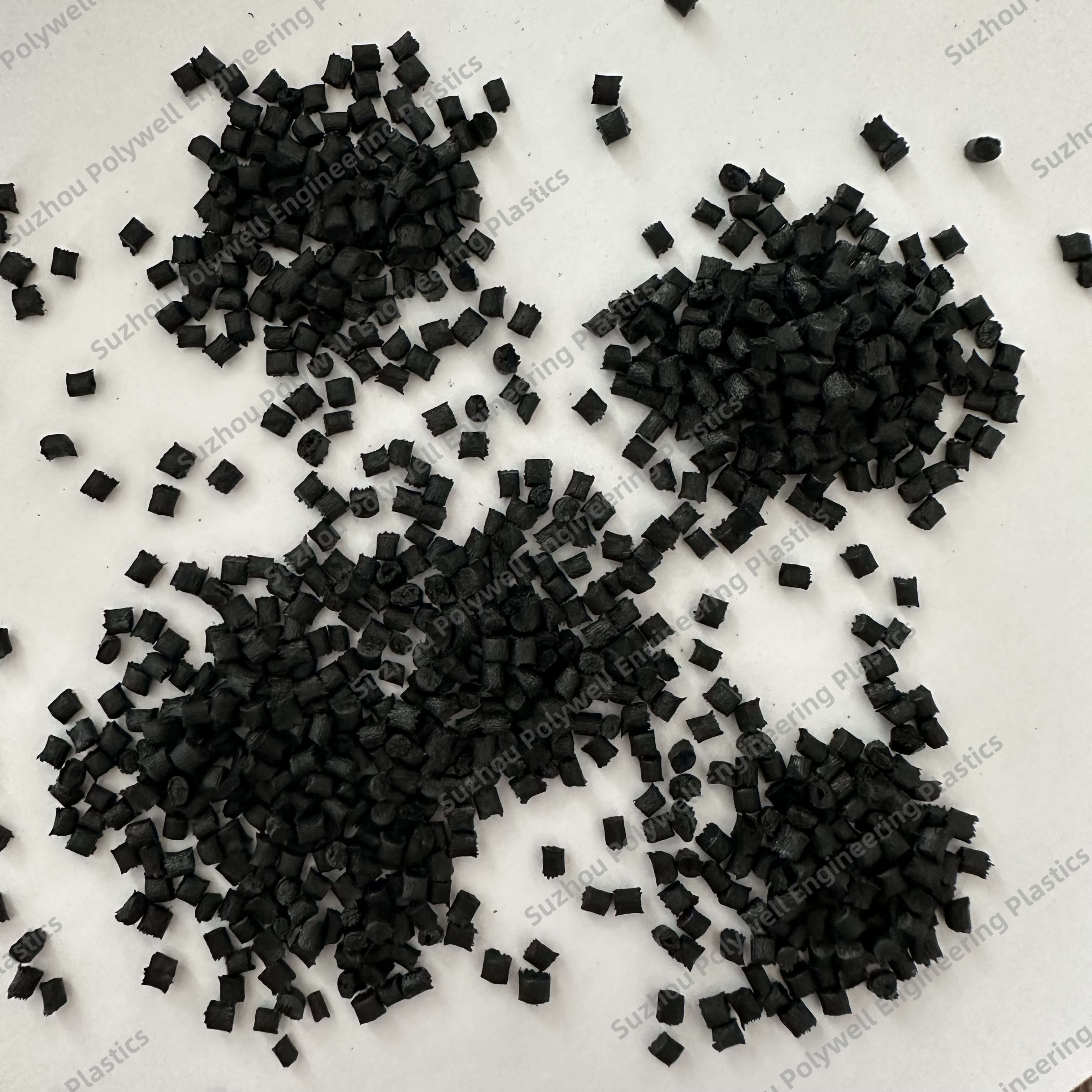

GF25 Renovatum Polyamidum significat plasticum technicale thermoplasticum alti praestantiae, cuius resina basis polyamidica, saepe Nylon 6 vel Nylon 66, cum 25% fibre brevibus vitrosum in pondere misceatur. Haec renovatio fundamentis proprietates materiae immutat, compositum creans quod potentiam, rigorem et resistentiam thermicam meliorem prae suo simili non impletivo offert. Additio fibrarum vitrosum valde augumentat vim trahendi et flectendi, simulque modulum materiae (rigiditatem) multum augebit, ita ut componentes rigidiores et stabiliores dimensionibus sub onere fiant. Temperatura Deflectionis Caloris (HDT) notabiliter melioratur, ut materia in locis altioris caloris recte operari possit, saepe supra 200°C ad Nylon 66-GF25. Praeterea, minor sitis et durabilitas faticae melior est comparata polyamidibus non renovatis. Tamen haec renovatio anisotropiam contrahendi inducit, id est contractio perpendicularis directioni fluxus maior est quam parallela, factor criticus qui in designando forma habendus est, ne distorquatur. Fibrarum quoque additio abrasivitatem auget, quod materialia resistentia attritionis in machinis elaborandi, sicut cochleae et cunei, requirit. Etiam si vis aucta sit, praesentia fibrarum vim ictus in aliquibus orientationibus minuere potest et materiam sensibiliorem scrobis reddere. GF25 Renovatum Polyamidum late usurpatur in applicationibus gravibus in industria automobilium (exempli gratia: tegmina motorum, ventiatores refrigerantes, brachia structurales), sectoribus electricis et electronicis (connectores, cassae) et apparatibus industrialibus (rotulae, axis, cassae machinarum), ubi excellentes proprietates mechanicae et thermicae praestantiam magnam conferunt.