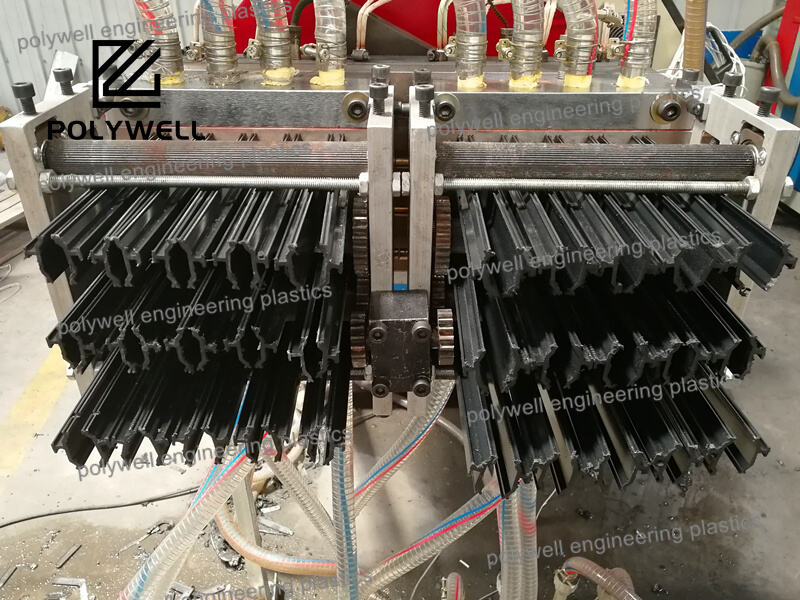

Terminus "extruder moulding" non est terminus technicus standard in industria plasticorum et verisimiliter confusio est duorum processuum distinctorum: extrusionis et formandi per injectionem. Ut claritas servetur, inter eos distinguere necessarium est. Extrusio est processus continuus ad producenda producta longa et uniforma ut tubi, sectiones et laminas creanda. In extrusione, materia continue liquefit et per matricem conicitur ad formam sectionis specificae dandam. Formatio per injectionem autem est processus cyclicus, ubi quantitas certa plastici fusi sub alta pressione in cavitatem formae clausae et refrigeratae inicitur, ut partes discretas tridimensionales efficiat. Machinae, processus regulatio et producta finalia pro his duobus methodis fundamentaliter differunt. Itaque in communicatione professionali, preciso usus terminorum est necessarius. Si contextus formas longas et continuas complectitur, terminus rectus est "extrusio". Si autem partes singulares et complexas, ut cassus vel continentes, efficiendas complectitur, terminus rectus est "formatio per injectionem". Usus terminologiae accurate intellectum praeventum facit et collaborationem efficacem in projectibus fabricationis et ingeniariae certam reddit.