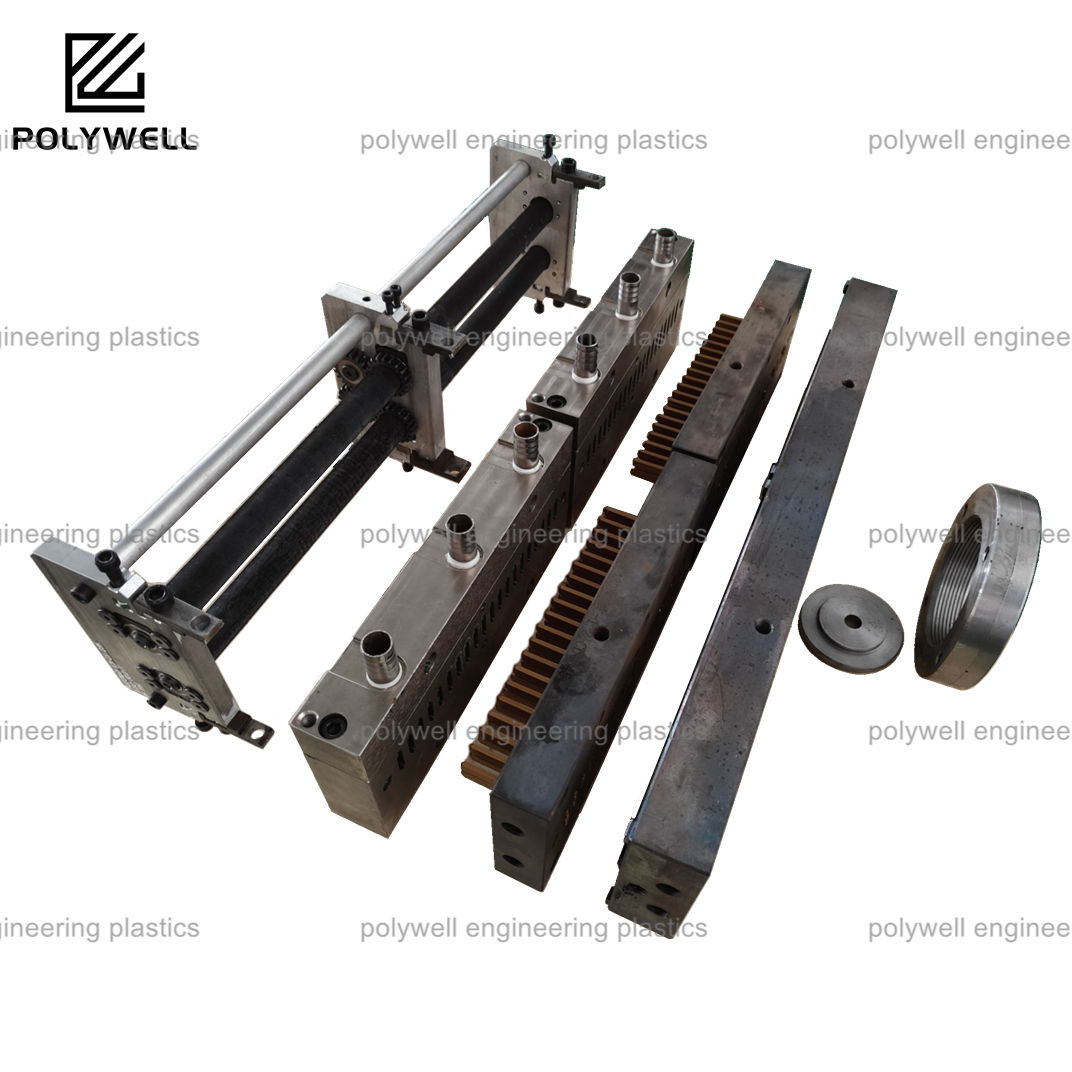

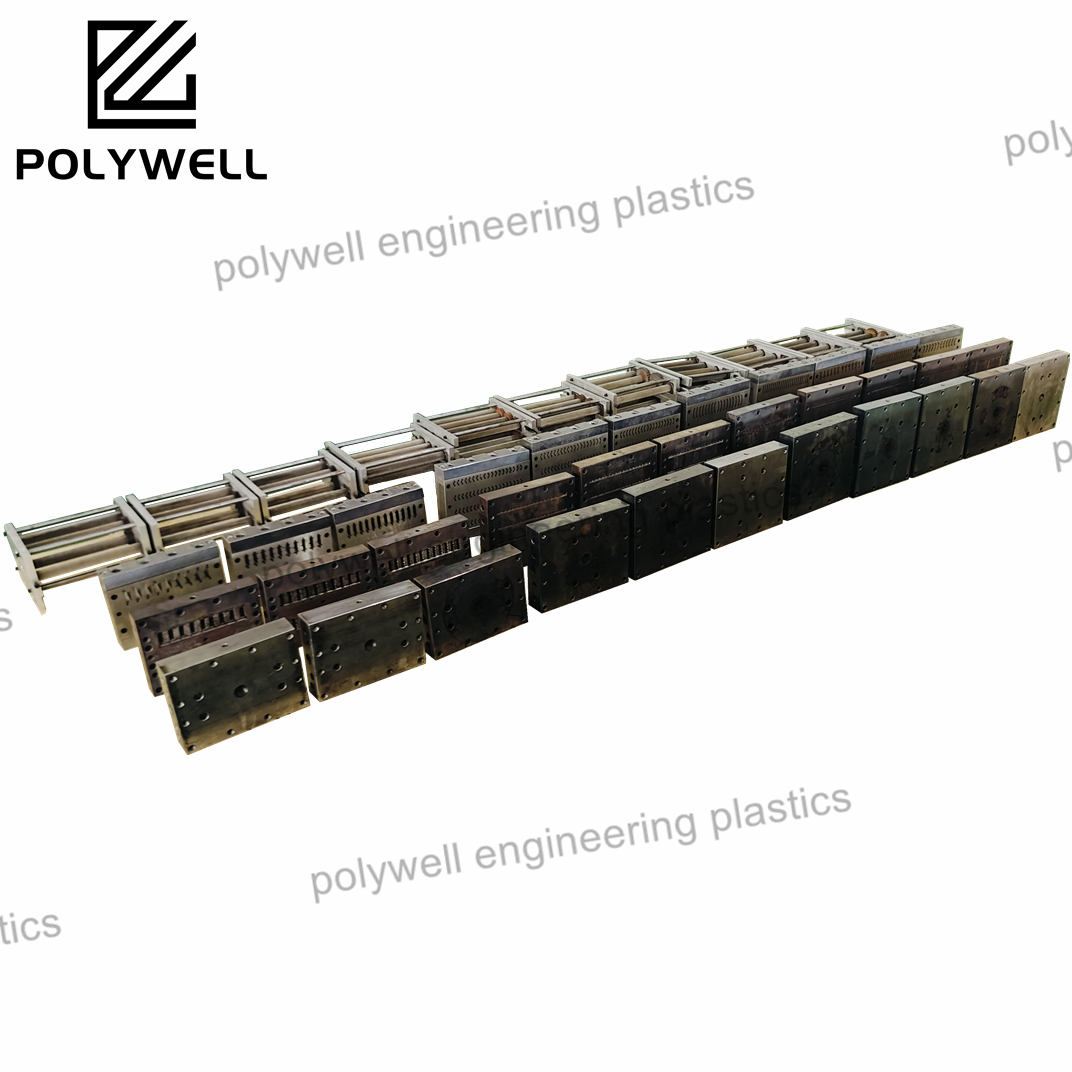

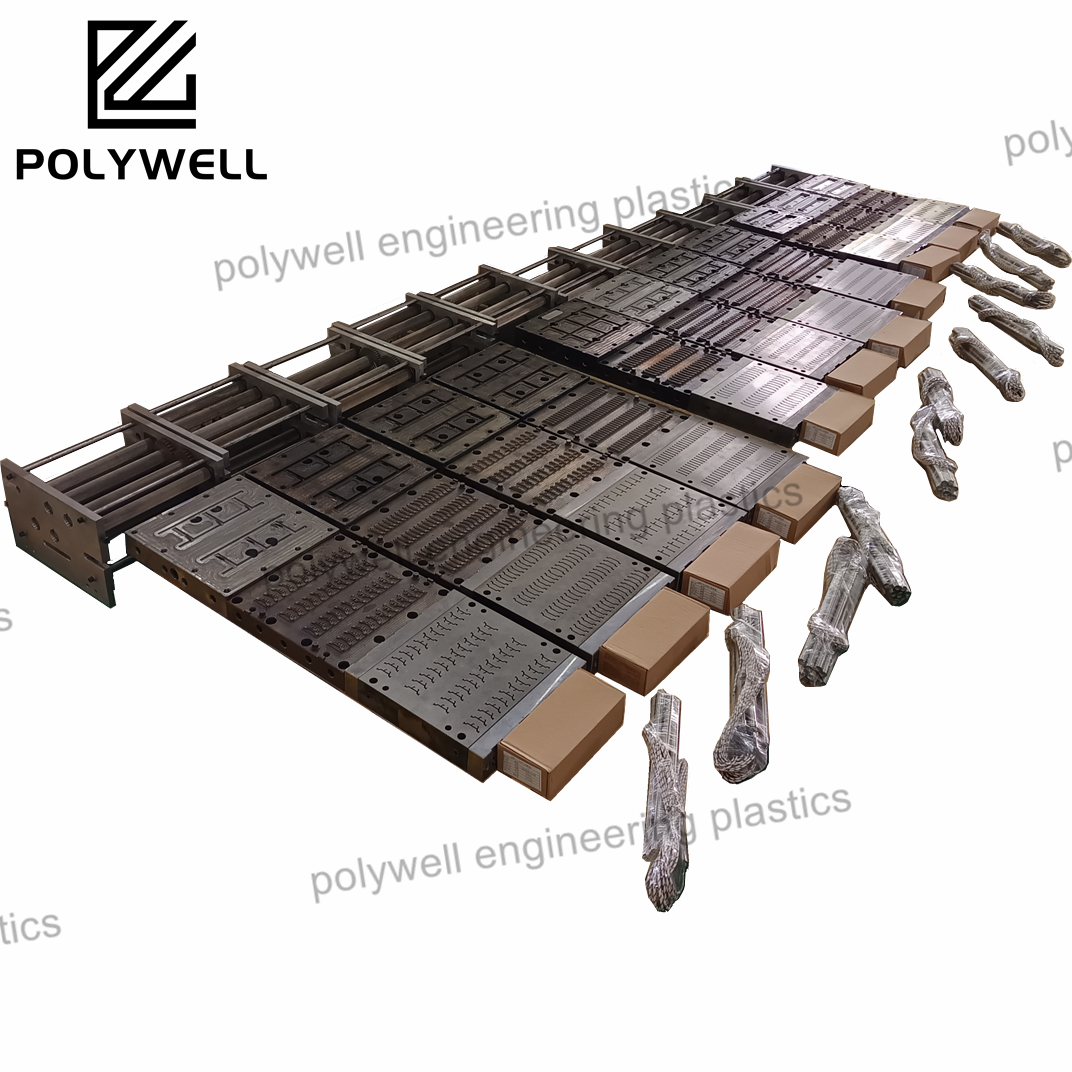

Դիե հեդ էքստրուդերը վերաբերում է այն կոնֆիգուրացիային, երբ ձևավորող դիեն ամրացված է հատուկ հանգույցին՝ դիե հեդին, որը իր հերթին միացված է էքստրուդերի փողային մասին: Այս տերմինը շեշտում է դիե հեդի ինտեգրված դերը որպես լրիվ միավոր ձևավորման գործընթացում: Դիե հեդը պասիվ պահակ չէ. այն պոլիմերային հալվածքի համար ակտիվորեն կառավարվող միջավայր է: Այն պարունակում է ներքին հոսքի անցքեր, որոնք ուղղորդում են պլաստիկը էքստրուդերի պտուտակի ծայրից դեպի դիեի անցք: Այս անցքերը նախագծված են այնպես, որ պտուտակից եկող պտտական, անկանոն հոսքը դարձնեն դիեի մուտքում լամինար և համասեղան հոսք: Դիե հեդը սարքավորված է իր սեփական՝ անկախ և ճշգրիտ կառավարվող տաքացման համակարգով, որը թույլ է տալիս օպերատորներին ճշգրիտ կարգավորել հալվածքի ջերմաստիճանը մինչև ձևավորման կետը, ինչը կարևոր է խտությունը կառավարելու և փայլուն մակերեսի վերջնամաս ապահովելու համար: Ինչպես, օրինակ, սահմանադրական էքստրուդերային տեխնոլոգիաներում սալիկների ծածկույթի համար, դիե հեդը նախագծված է այնպես, որ սալիկը կենտրոնապես ներմուծվի հալվածքի հոսքի մեջ: Դիե հեդի հանգույցի հաստատությունը կարևոր է, քանի որ այն պետք է դիմադրի էքստրուդերի պտուտակի կողմից ստեղծված բարձր ճնշումներին: Ուստի դիե հեդ էքստրուդերը ներկայացնում է մոդուլային և բարձր կառավարվող մոտեցում պրոֆիլի ձևավորման համար, որտեղ հալվածքի հատկությունները կարող են օպտիմալացվել անմիջապես նախքան այն վերջնական արտադրանքի ձև ստանալը: