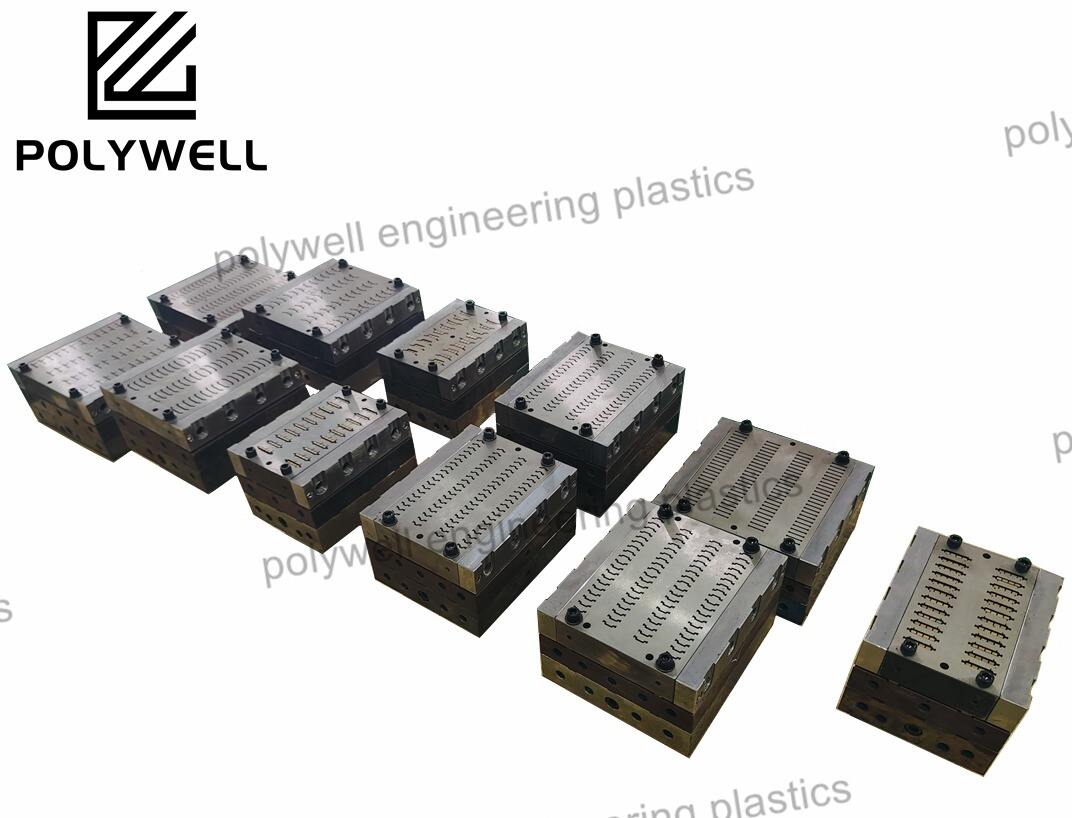

PA66 GF25 Thermal Break rwb thaiv tsev sawb txoj kev Molding Tuag nrog Customized Shapes thiab Kab noj hniav

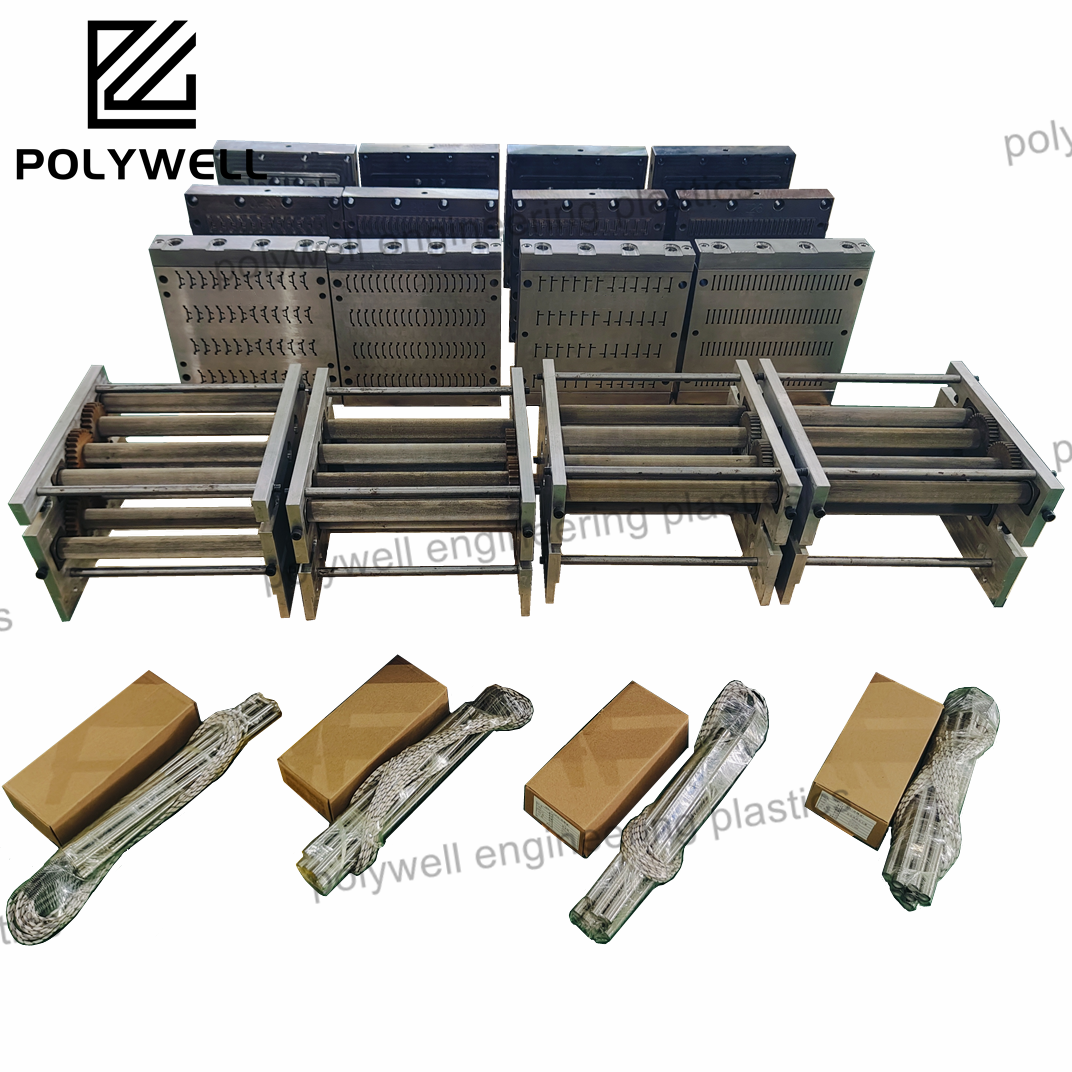

Extrusion Nylon Chain Guide PA66 Runway Guide Polyamide Rail Guide Mold

- Saib xyuas

- Cov khoom pom zoo

Kev Pabcuam Tomqab Muag: Cov Kws Ua Haujlwm Muaj Kev Pabcuam Txawv Tebchaws

Warranty: 1 Xyoo

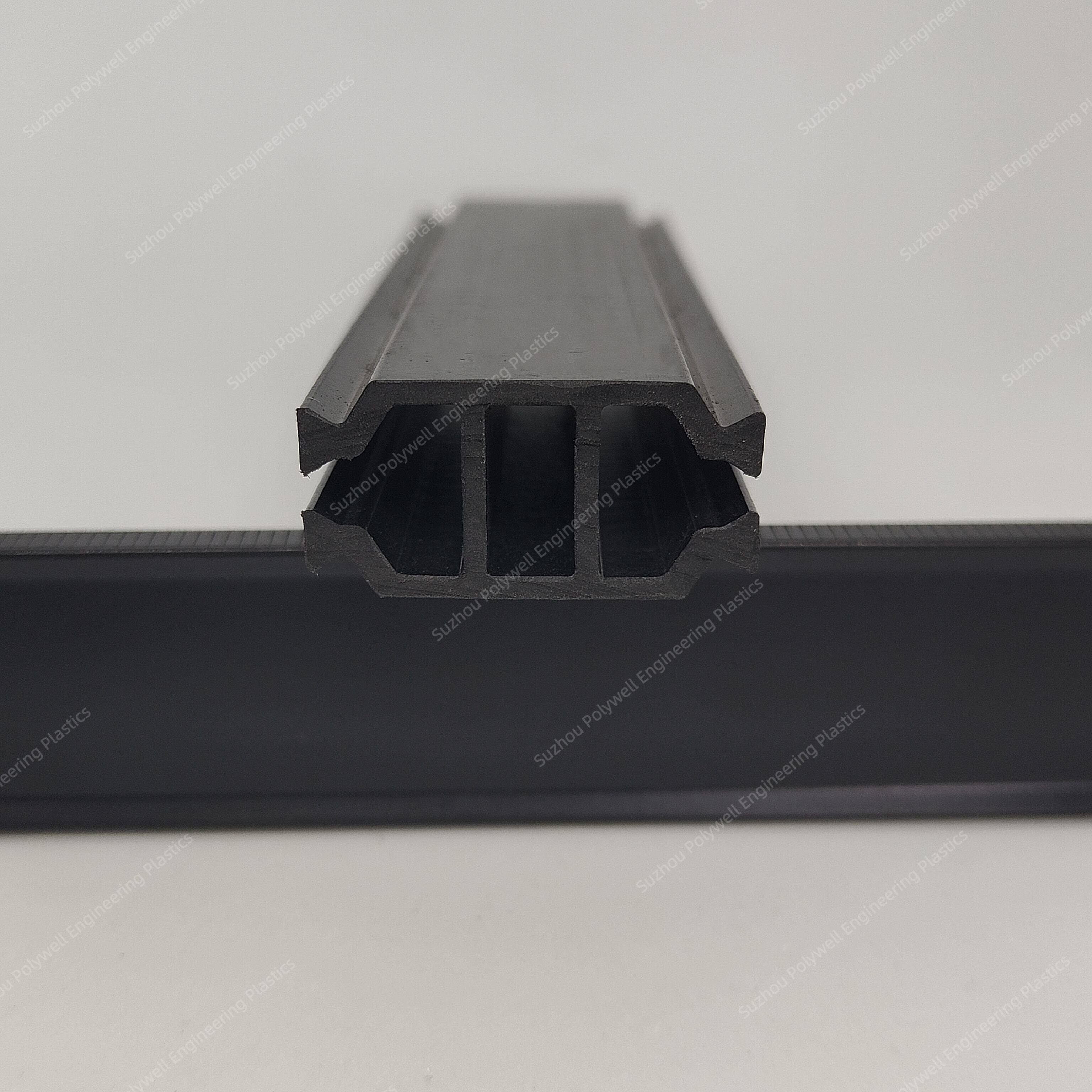

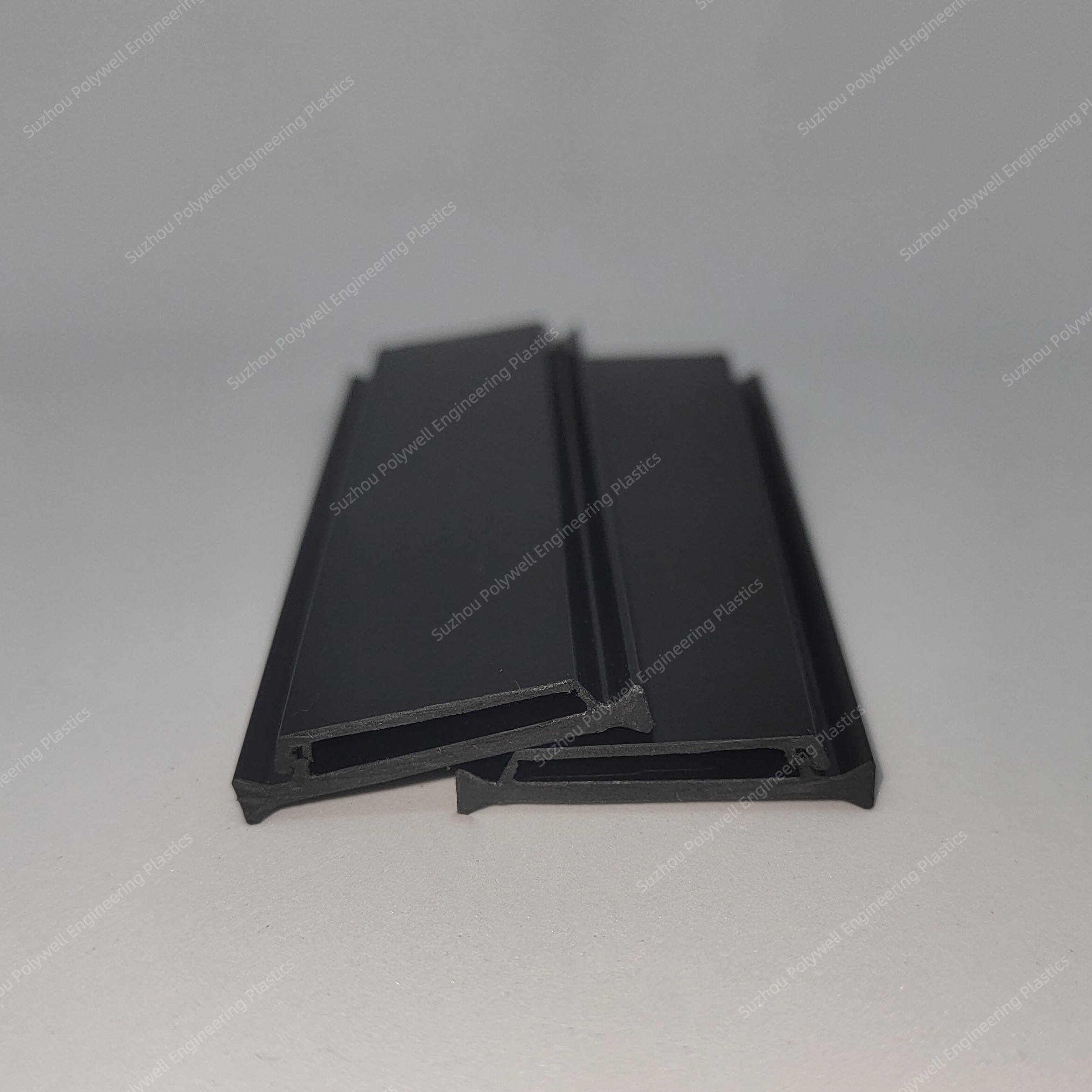

Yam khoom: polyamide strips

Automation: Tsis siv neeg

ransport Pob: Yas Ua Npuas Ncauj Zaj duab xis lossis Plywood Case

Specification: 60 hli / 80mm / 100mm / 120mm / 140mm / 160mm / 200mm

Trademark: Polywell

Keeb kwm: Zhangjiagang City, Suav teb

Khoom siv: Stainless hlau

Daim Ntawv Thov: Thermal Break Profiles Ntau Lawm Kab

Tsim nyog Strip Shape: Kuv hom, C hom thiab lwm yam yooj yim hom

Customized: Customized

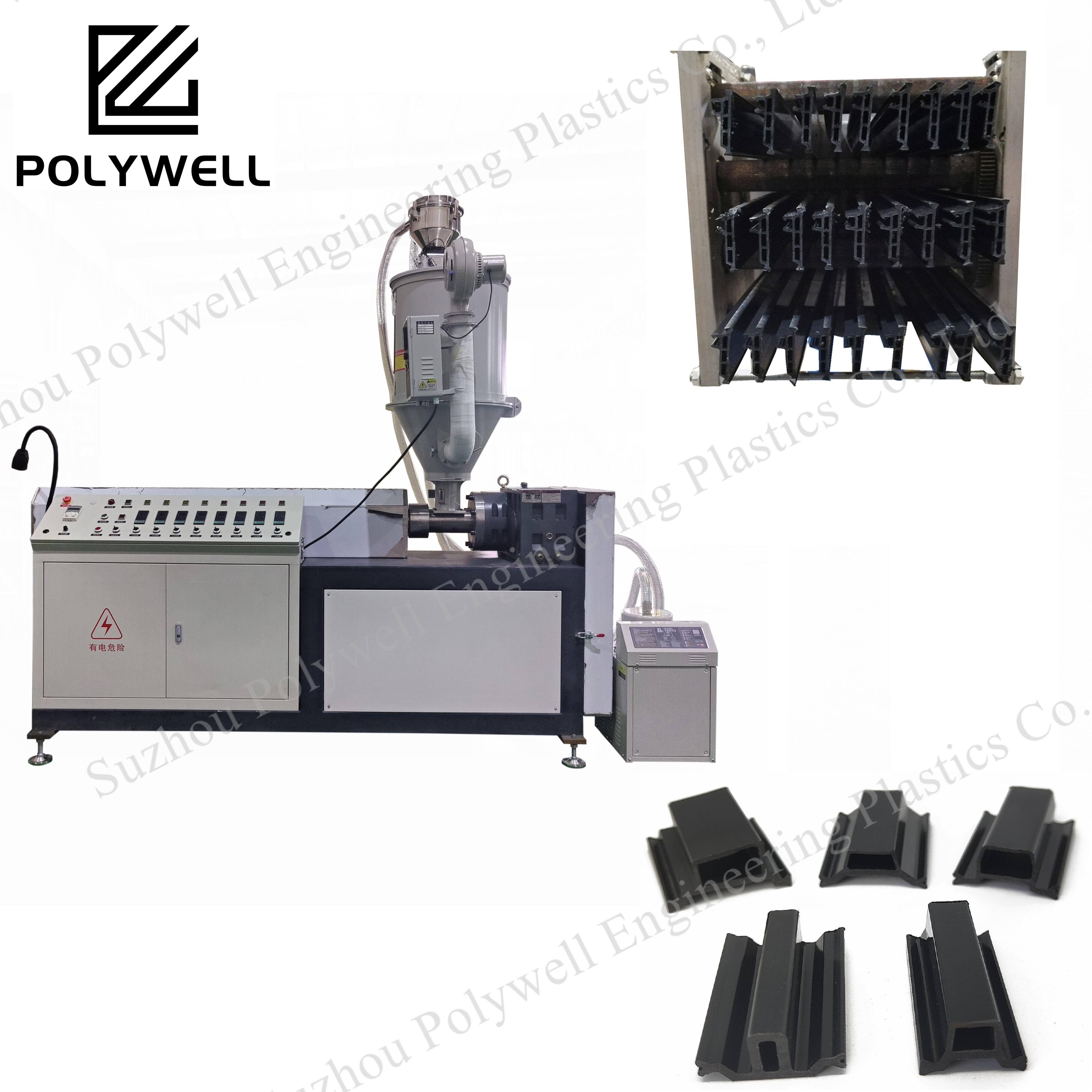

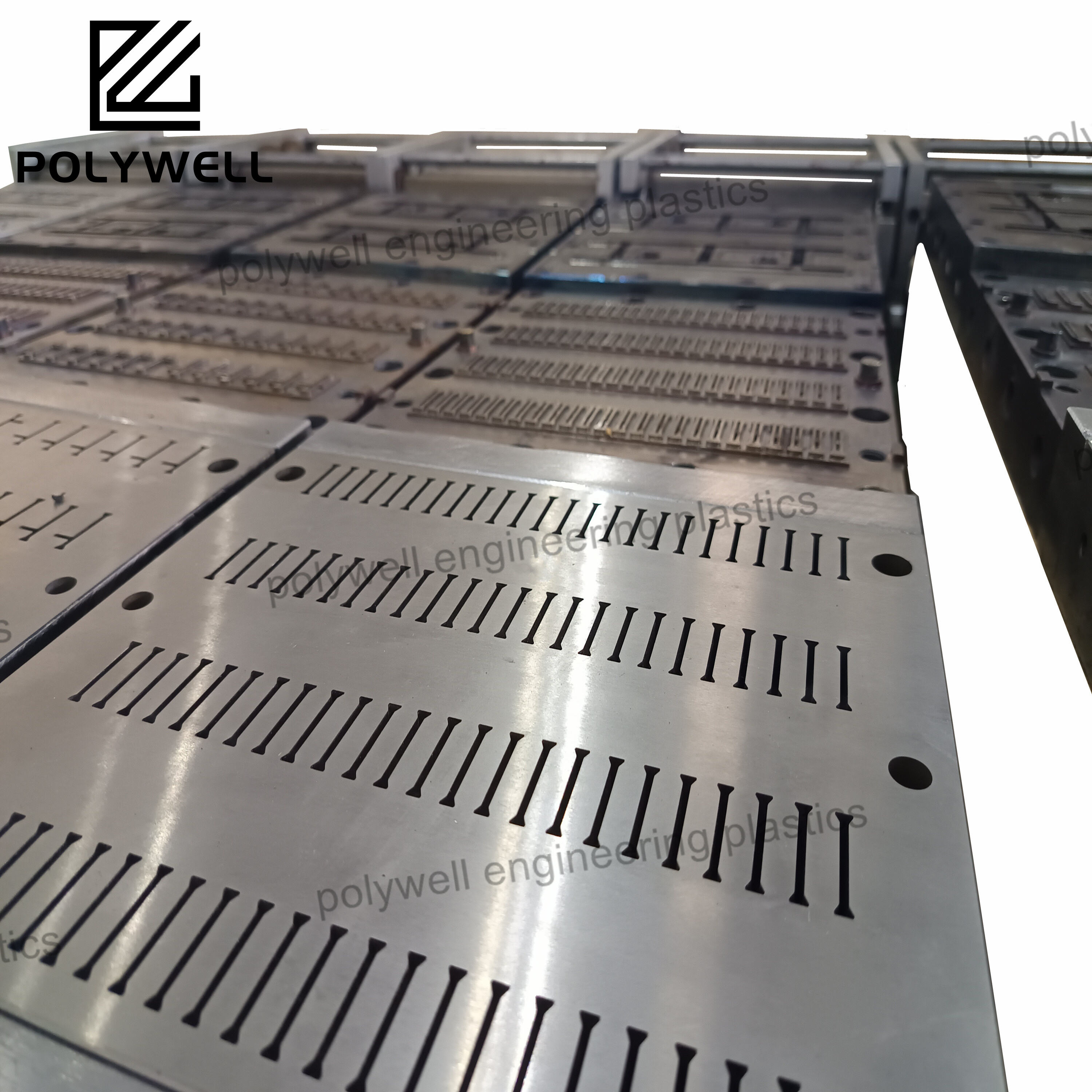

Thermal break profile extrusion pwm yeej ib txwm nruab rau ntawm ib lub ntsia hlau yas extruding tshuab. Lawv yog siv los tsim thiab tsim PA thermal so strips.

Dab tsi yog pwm hauv yas?

Lub pwm yog ib qho hollow hlau thaiv rau hauv uas molten yas yog txhaj los ntawm ib qho kev ruaj khov.

Dab tsi yog yas pwm rau PA profile extrusion kab?

PA profile txhais tau tias polyamide thermal so strips. Uas yog ib qho ntawm cov ntaub ntawv siv ntau xyoo los tsim cov thermal so hauv cov ntaub thaiv phab ntsa, cov qhov rais lag luam, qhov rooj, thiab lwm yam. Nws yog ib qho ntxiv polyamide sawb, uas tshwm sim raws li cov khoom siv tsis yog xim hlau, cov khoom sib xyaw, cov khoom siv, thiab yog ntsia nruab nrab ntawm sab hauv thiab sab nrauv profiles ntawm lub qhov rais uas tsim ib qho kev thaiv thaiv ntawm ob.

Cov duab, qhov loj thiab qhov tso zis ntawm polyamide strips yog txiav txim los ntawm cov pwm yas. Yog li ntawd, yas pwm yog ib qho tseem ceeb heev thiab indispensable ib feem ntawm polyamide strips extrusion kab.

Polyamide Thermal Strip Processing Txheej txheem

PA66GF25 granules yog qhuav thiab nkag mus rau hauv lub tshuab chim los ntawm lub hopper. Cov granules nyob rau hauv kev sib cuag nrog lub tshuab ntsia hlau, thiab txav mus rau lub pwm nrog kev sib hloov ntawm cov ntsia hlau.

Raws li qhov sib txawv ntawm lub tshuab ntsia hlau thiab lub thoob yog me me, cov granules yog rhuab nyob rau hauv qhov sib txawv nyob rau hauv tus txheej txheem ntawm mus rau pem hauv ntej. Lawv yog plasticized rau nylon molten xeev los ntawm qhov kub thiab txias ntawm hluav taws xob cua sov lub nplhaib lub cev. Lub xeev molten ntawm nylon yog hloov mus thiab zoo li tus tom qab nkag mus rau hauv pwm, thiab thaum kawg extruded rau hauv tshav kub rwb thaiv tsev strips.

Dab tsi yog pwm hauv kev tsim khoom?

Pwm, kuj spelled pwm, cuab yeej los yog tuag. Hauv kev tsim khoom, kab noj hniav lossis matrix uas muaj cov kua dej lossis cov khoom yas zoo li tus yam xav tau ua tiav. Cov khoom molten, xws li PA 6.6 khoom, yog poured los yog yuam rau hauv pwm thiab tso cai rau harden.

Yas txhaj molding yog txoj kev siv ntau tshaj plaws los ua cov khoom yas. Kev txhaj tshuaj molding yog ib txoj hauv kev uas cov yas molten feem ntau yog cov thermoplastic yog nchuav rau hauv cov pwm hlau uas muaj hlau lossis txhuas. Thaum cov khoom molten tau muab tso rau hauv pwm, nws yuav tsum tau tso cai kom txias kom txog thaum nws solidifies ua ntej cov khoom kawg tuaj yeem muab rho tawm. Cov khoom siv pwm xws li ABS, acetal, nylon 66, low-density polyethylene (LDPE), high-density polyethylene (HDPE), polycarbonate, polypropylene, polystyrene thiab thermoplastic elastomer yog siv. Yas txhaj tshuaj molding yog siv nyob rau hauv ntau yam kev lag luam nrog rau kev tsim kho, khoom noj khoom haus thiab dej haus, kev kho mob thiab tshuaj.

Peb lub tuam txhab tsuas yog tsim cov pwm rau nylon 66 khoom.

Dab tsi yog extrusion molding txheej txheem?

Extrusion molding (tseem hu ua plastification extruding) yog txheej txheem uas cov pawg ntawm cov khoom molten hauv pwm raug thawb tawm mus rau lwm hom ntawm lwm yam khoom kawg nyob rau hauv siab.

Pwm txiav txim siab cov duab thiab nthuav dav qhov ntau thiab tsawg ntawm cov khoom kawg.

Cov pwm tsim li cas?

Cov txheej txheem molding siv lub siab thiab cua sov los sau cov kab noj hniav ntawm cov pwm, ib lub thav duab nruj kuj hu ua matrix. Cov khoom siv raw, feem ntau yog ib qho pliable zoo li yas yog khaws cia nyob rau hauv siab kom txog thaum nws solidifies los yog pib harden.

Dab tsi yog extrusion molding siv rau?

Extrusion yog cov txheej txheem tsim khoom siv los ua cov kav dej, hoses, haus straws, curtain lem, rods, thiab thermal so profiles. Cov granules yaj mus rau hauv cov kua uas yog yuam los ntawm ib tug tuag, tsim ib tug ntev 'tube zoo li' zoo li. Cov duab ntawm cov tuag txiav txim siab cov duab ntawm 'tube zoo li' cov khoom.

Qhov zoo:

1. Peb cov engineers ua raws li cov pwm tsim tawm txhua lub lim tiam kom paub tseeb tias txhua tus nyob hauv lub sijhawm.

2. Peb tsis tu ncua optimize tus khiav tsim kom cov tuag yooj yim rau kev khiav hauj lwm thiab cov khoom extrusion.

3. Peb yuav muab cov kev hloov kho kev xav raws li tus neeg siv khoom kos duab, thiab txhim kho cov duab kos raws li cov neeg siv khoom xav tau.

4. Yog tias txhua yam yog OK, peb yuav ua qhov kawg tshuaj xyuas ntawm cov pwm thiab cov khoom ua ntej xa khoom.

5. Tom qab tus neeg siv khoom tau txais cov pwm, yog tias muaj teeb meem hauv kev siv nws, peb tuaj yeem mus rau ntawm qhov rooj thiab muab kev taw qhia ntawm qhov chaw.

Name |

PA tshav kub rwb thaiv tsev profiles pwm |

Cov khoom siv yas |

Txa66-gf25 |

Hlau ntawm Cavity & Core |

TIAB SA 1.2379 |

Cov naj npawb ntawm Cavity |

Customized |

Hardness ntawm Cavity & Core |

48-52 HRC / 55-60 HRC |

Pwm Accessories |

HASCO Txuj |

Txias qhov system |

Dej Txias |

Tus khiav |

Txias |

Tsis txhawb |

Nyob ib ncig ntawm 20-28 hnub ua haujlwm |

Ntim |

Plywood case |

Peb ntawv |

T / T, Western Union, Nyiaj Gram |

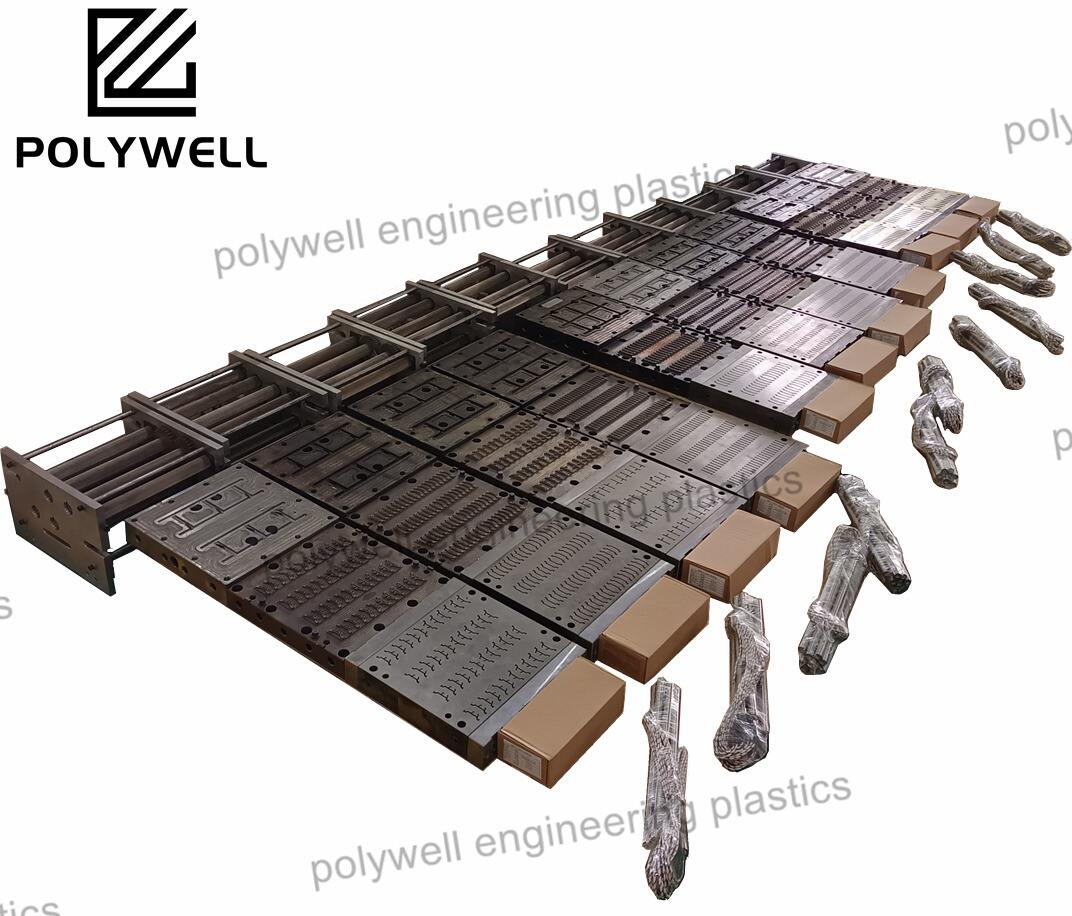

Peb qhov kev pabcuam pwm tsim thiab kev tsim kho:

Lub precision ntawm lub cuab yeej yog tus yuam sij rau qhov zoo ntawm ib feem. Kev tsim cov cuab yeej yog kev kos duab. Tias yog vim li cas peb tsim thiab sim peb cov cuab yeej rau cov qauv nruj tshaj plaws. Txawm hais tias koj xav tau ib lub cuab yeej rau prototyping lossis siab ntim ntau cov kab noj hniav, peb yuav ua kom tiav sai thiab raug.

Packing & Delivery

Peb feem ntau tso txhua tus qauv rau hauv ib lub thawv plywood kom paub tseeb tias tus qauv yog ruaj khov thaum lub sijhawm thauj mus los.

Qhov hnyav ntawm txhua pwm yog nyob ib ncig ntawm 60-200kg. Nws nyob ntawm qhov loj ntawm pwm.

Peb feem ntau xav tau 28-35 hnub ua haujlwm los tsim ib tus qauv. Tom qab ntawd, peb yuav ua tus qauv test kom paub tseeb tias ob qho tib si tus qauv thiab cov polyamide strips tsim los ntawm tus qauv no yog tsim nyog.

EN

EN