Nylon Polyamide Sawb Thaum tshav kub kub rwb thaiv tsev zoo siv rau zawv zawg Aluminium qhov rai thiab qhov rooj

Nylon Chain Guide Profile Rail Guide Runway Guide PA66 Profile

- Saib xyuas

- Cov khoom pom zoo

Dab tsi yog a rwb thaiv tsev kub strip?

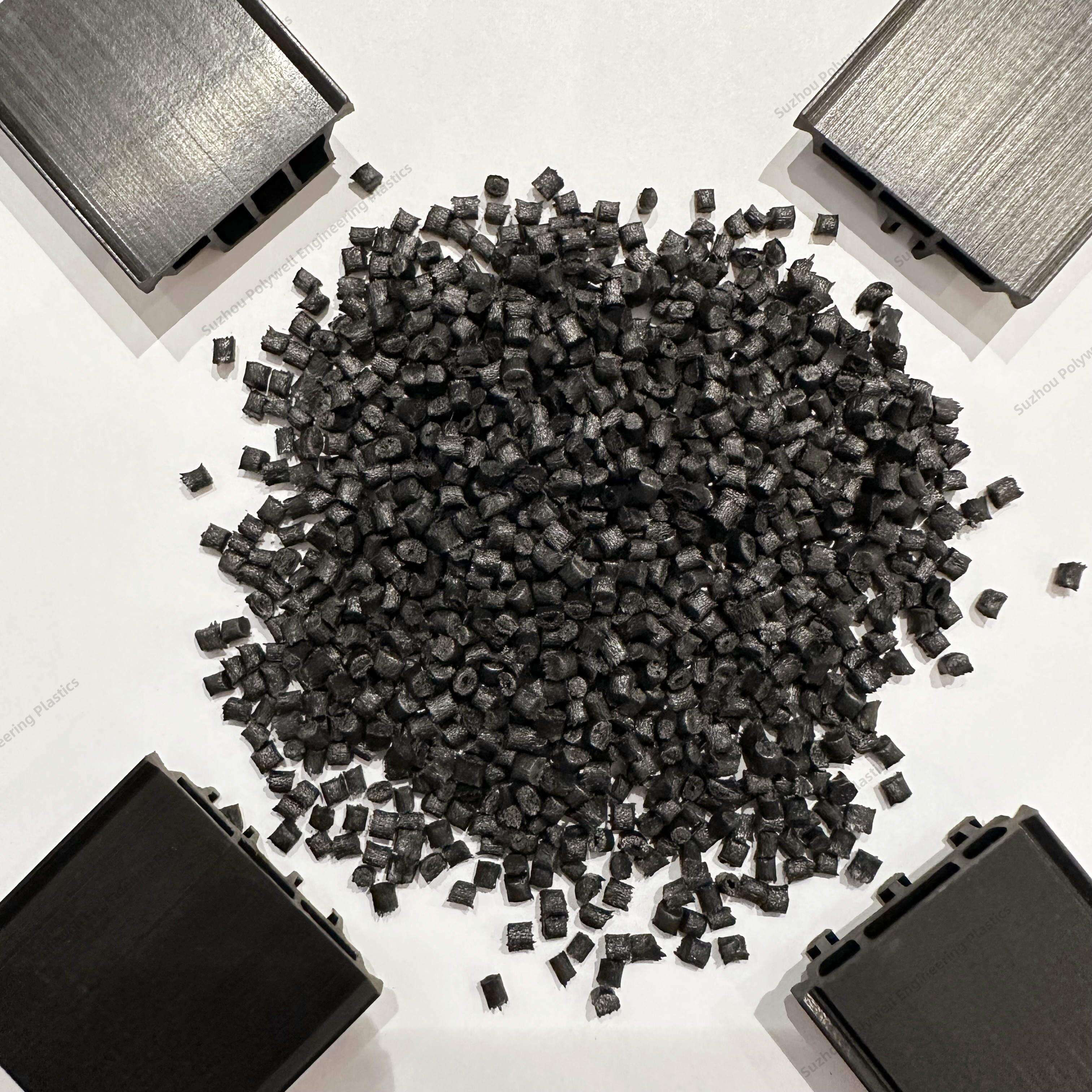

Rwb thaiv tsev ntawm aluminium qhov rooj thiab qhov rais kaw nrog rwb thaiv tsev sawb yog ib qho nrog cov iav fiber reinforced polyamide nylon (PA66), hu ua Nylon 66 rwb thaiv tsev strips, expansion coefficient yog me me, tshav kub-resistant, thiab anti-aging zog.

High Precision Rau Aluminium Sash Qhov rai Ncej PA66 25% Fiberglass Thermal rwb thaiv tsev barrier strips.

Ntxig rau hauv cov thermal so aluminium profiles, thiab yog ib feem ntawm lub zog txuag qhov rais rau kev txo cov cua sov.

Cov duab kuv polyamide thermal barrier khoom tuaj yeem tiv thaiv lub qhov rais thav duab los ntawm plua plav thiab dej thiab tuaj yeem paub qhov zoo dua Uf tus nqi los ntawm kev sib khi nrog cov roj hmab profile, feem ntau siv rau ntawm lub sash.

Puas yog polyamide strips tuaj yeem rhuav aluminum extrusion assemblies?

Yog lawm.

Cov txheej txheem insulating polyamide strips tau siv rau thermally rhuav tshem aluminium extrusion cov rooj sib txoos rau ntau tshaj 30 xyoo thiab tau siv nyob rau hauv North America rau ntau tshaj kaum xyoo. Polyamide strips muaj nyob nrog ntau qhov kev teeb tsa kom tau raws li cov kev ua tau zoo sib txawv. Tsim kom muaj thermal so siv lub tshuab polyamide sawb entails tus txheej txheem 3 kauj ruam.

1. Profile knurling

2. Txoj hlua ntxig

3. Crimping

T h e Muaj nuj nqi ntawm Thermal Break Strips hauv Qhov rai

Kev tawg choj kub-insulated aluminium alloy qhov rooj thiab qhov rais yog faib cov thawj tag nrho lub cev aluminium alloy profile rau hauv ob lub hauv paus ntawm cov tsoos aluminium alloy qhov rooj thiab qhov rais. Tag nrho cov tshav kub-insulating profile enables lub tshav kub-insulating sawb thiab aluminium alloy los ua ke dais lub load tshwm sim los ntawm lub iav nws tus kheej qhov hnyav, cua siab thiab kub siab. Yog li ntawd, qhov kev siv ntawm cov hluav taws kub rwb thaiv tsev sawb txiav txim siab tias nws yuav tsum muaj lub zog siab thiab kev ruaj ntseg zoo nyob rau tib lub sijhawm, txwv tsis pub nws yuav yooj yim ua rau lub qhov rooj, qhov rais thiab cov ntaub thaiv phab ntsa tawg thiab poob tawm, ua rau muaj kev phom sij loj thiab muaj kev nyab xeeb.

Lo lus "choj" nyob rau hauv lub npe "tawg choj txhuas" txhais tau hais tias "kub thiab txias choj" nyob rau hauv cov ntaub ntawv science, thiab lo lus "tawg" yog rau cov lus txiav txim, uas txhais tau tias "txiav tawm lub kub thiab txias choj". Tshwj xeeb hais lus, aluminium alloy yog hlau nruab nrab uas muaj zog thermal conductivity. Thaum nws sib tsoo nrog qhov kub thiab txias sab nraum lub tsev los ntawm qhov sib txawv loj, aluminium alloy ua "choj" rau cov cua sov. Siv hom khoom no los ua lub qhov rooj thiab qhov rais, nws yuav muaj cov rwb thaiv tsev tsis zoo thiab. Txawm li cas los xij, tus choj tawg ntawm txhuas yog txhawm rau tshem tawm cov aluminium alloy los ntawm nruab nrab, thiab cov thermal conductivity ntawm cov yas yuav tsis muaj zog dua li cov hlau. Lub disconnected aluminium alloy yog txuas nrog cov yas tawv, kom cov cua sov yuav tsis yooj yim ntws mus rau tag nrho. cov khoom siv, yog li cov rwb thaiv tsev kub yuav zoo dua, uas yog lub hauv paus ntawm lub npe "pob zeb tawg aluminium (alloy)".

Daim ntawv thov thiab qhov zoo

Aluminium qhov rais muaj qhov tsis zoo ntawm kev txwv thermal rwb thaiv tsev. Nws tus nqi Uf, uas qhia txog cov cua sov uas dhau los ntawm lub qhov rais profile, tsuas yog siab dhau. Yog tias koj lub qhov rais muaj cov txheej txheem txhuas profile, koj lub tsev yuav tsim cov hws, los yog pwm. Dhau li ntawm qhov ua rau cov nqi kho mob siab, cov pwm hauv tsev kuj ua rau muaj teeb meem ua pa xws li mob hawb pob.

Tab sis qhov tsis zoo tam sim no tau raug tshem tawm tag nrho yog tias koj nruab polyamide strips hauv aluminium qhov rais. Qhov tseeb, ua tsaug rau kev tsim kho tshiab tsim lub npe hu ua thermal so profiles, aluminium yog qhov tsawg kawg yog zoo li nws cov neeg sib tw. Nyob rau hauv cov ntaub ntawv no, ua los ntawm cov tshuab tshwj xeeb, ib tug polyamide sawb yog muab tso rau ntawm lub puab thiab sab hauv seem ntawm lub profile.

Polyamide yog cov yas uas insulates ntau dua 500 npaug zoo dua li txhuas, yog li thermal so profiles muaj qis dua Uf tus nqi - thiab xa cov cua sov los yog txias dua. Yog li ntawd, koj lub tsev nyob sov dua nyob rau lub caij ntuj no, thaum ua kom sov sab nraud yooj yim dua nyob rau lub caij ntuj sov.

Yam ntxwv ntawm polyamide strips

Polyamide thermal so yog extruded nyob rau hauv qhuav lub xeev tab sis lawv nqus noo noo los ntawm ib puag ncig tom qab ntau lawm raws li lub sij hawm dhau mus. Moisture Level nyob ntawm cov xwm txheej hauv qab no:

- Ambient kub

- Ambient humidity

- Lub sijhawm khaws cia

Thaum lub caij ntuj sov, thaum qhov kub thiab av noo nyob rau hauv qhov chaw cia siab dua li niaj zaus, cov ntaub ntawv insulating nqus dej noo ntau dua li cov caij nyoog ntxiv, txawm tias khaws cia kom zoo.

Yuav ua li cas khaws polyamide thermal so strips?

Ua ntej, Khaws cov ntaub ntawv kab rov tav txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhawm rau txhuam nws Txhawb nqa ntev ntev.

Thib ob, Khaws qhov ntsuas kub ntawm qhov kub ntawm 15 txog 20 ° C.

Thib peb, Tiv thaiv kev ya raws.

Pob

Rau txhua qhov kev qhia / duab, lawv tuaj yeem muab ntim hauv kab, qhov ntev yuav yog 6 meters, lossis kho.

Rau cov duab "I" "C", thiab qee cov duab yooj yim, lawv tuaj yeem ntim hauv cov pob. Qhov ntev feem ntau yog ib puag ncig 300-600 meters ib pob.

Peb qhov kev pabcuam hais txog kev xeem

1.Size precision soj ntsuam rwb thaiv tsev, raws li lub teb chaws tus qauv GB / T23615.1-2017, qhov loj precision ntawm nrhiav kom tau cov neeg muas zaub ntawm tshav kub rwb thaiv tsev sawb.

2.Nrhiav thiab tsom xam ntawm rwb thaiv tsev ntawm cov qauv sab hauv, raws li lub teb chaws tus qauv GB / T23615.1-2017.analyze lub internal qauv ntawm rwb thaiv tsev kuaj xyuas rau cov neeg muas zaub.

3.Insulation density test, raws li lub teb chaws tus qauv GB / T23615.1-2017, daim ntawv thov ntawm hluav taws xob hnyav ntsuas ntsuas ntsuas qhov ntom ntom.

4.Raws li lub teb chaws tus qauv GB/T23615.1-2017, lub rwb thaiv tsev chav tsev kub transverse tensile yam ntxwv tus nqi, uas tsis yog-notched cuam tshuam lub zog, kub kub thiab transverse tensile yam ntxwv tus nqi ntawm kev xeem.

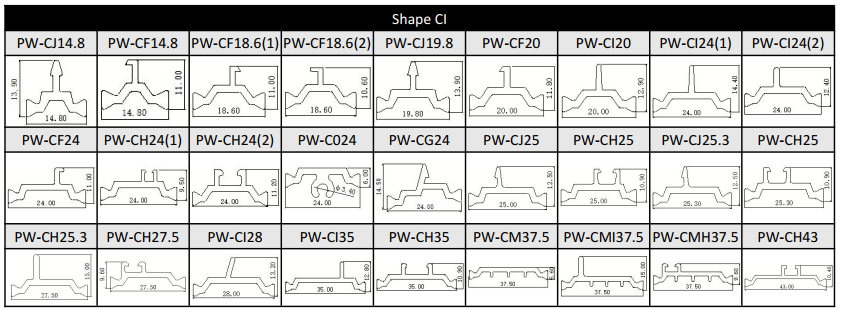

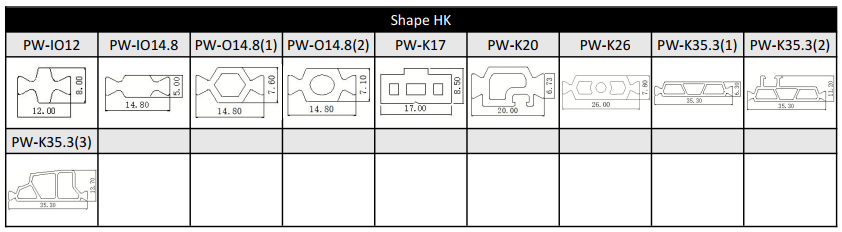

Cov duab sib txawv:

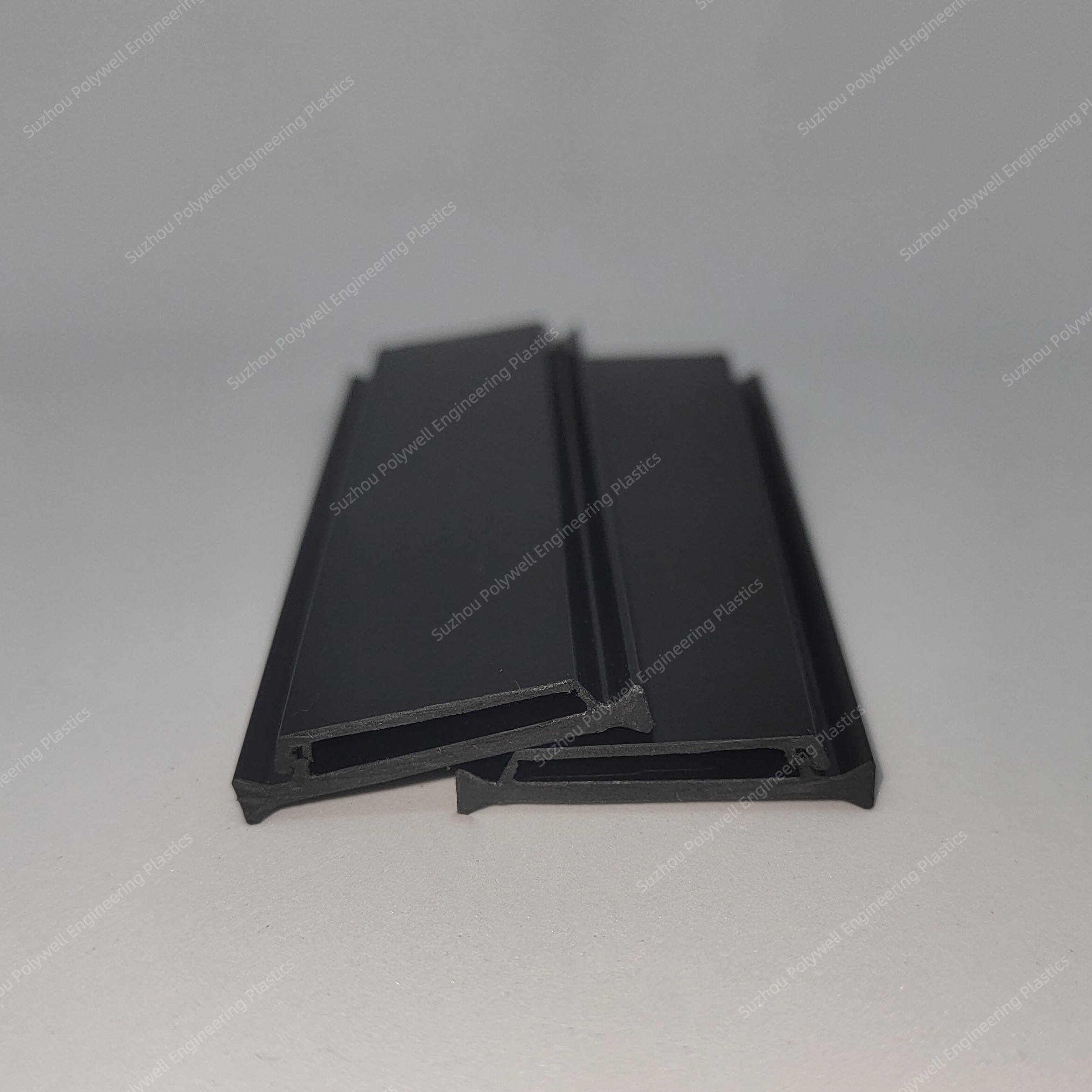

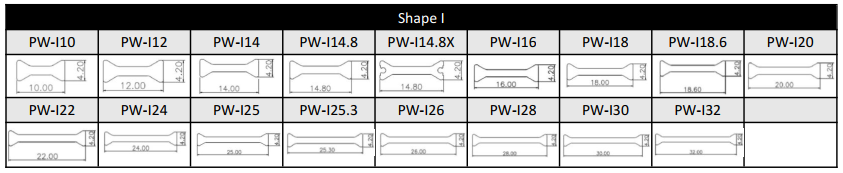

I-type thermal so strip yog ib qho khoom siv rwb thaiv tsev rau cov qhov rooj thiab qhov rais, nrog cov duab zoo ib yam li cov ntawv Askiv loj "Kuv". Nws yog thawj tiam thiab cov duab yooj yim tshaj plaws ntawm polyamide strips.

Raws li lwm hom thermal break strips, qhov zoo ntawm I-type strips yog tias lawv qhov ntev ntev tuaj yeem zoo dua adapts rau qhov dav ntawm cov rooj thiab qhov rais, txhim kho qhov thermal break effect.

Tsis tas li ntawd, hom I rwb thaiv tsev strips kuj tuaj yeem hloov mus rau qhov sib txawv qhov rooj thiab qhov rai qhov ntau thiab tsawg thiab cov kev qhia tshwj xeeb los ntawm lawv tus kheej cov duab thiab cov qauv, nrog kev hloov pauv siab thiab hloov tau.

Rau I-type strips, peb tuaj yeem muab qhov loj me hauv qab no lossis kho raws li tus neeg siv khoom kos duab.

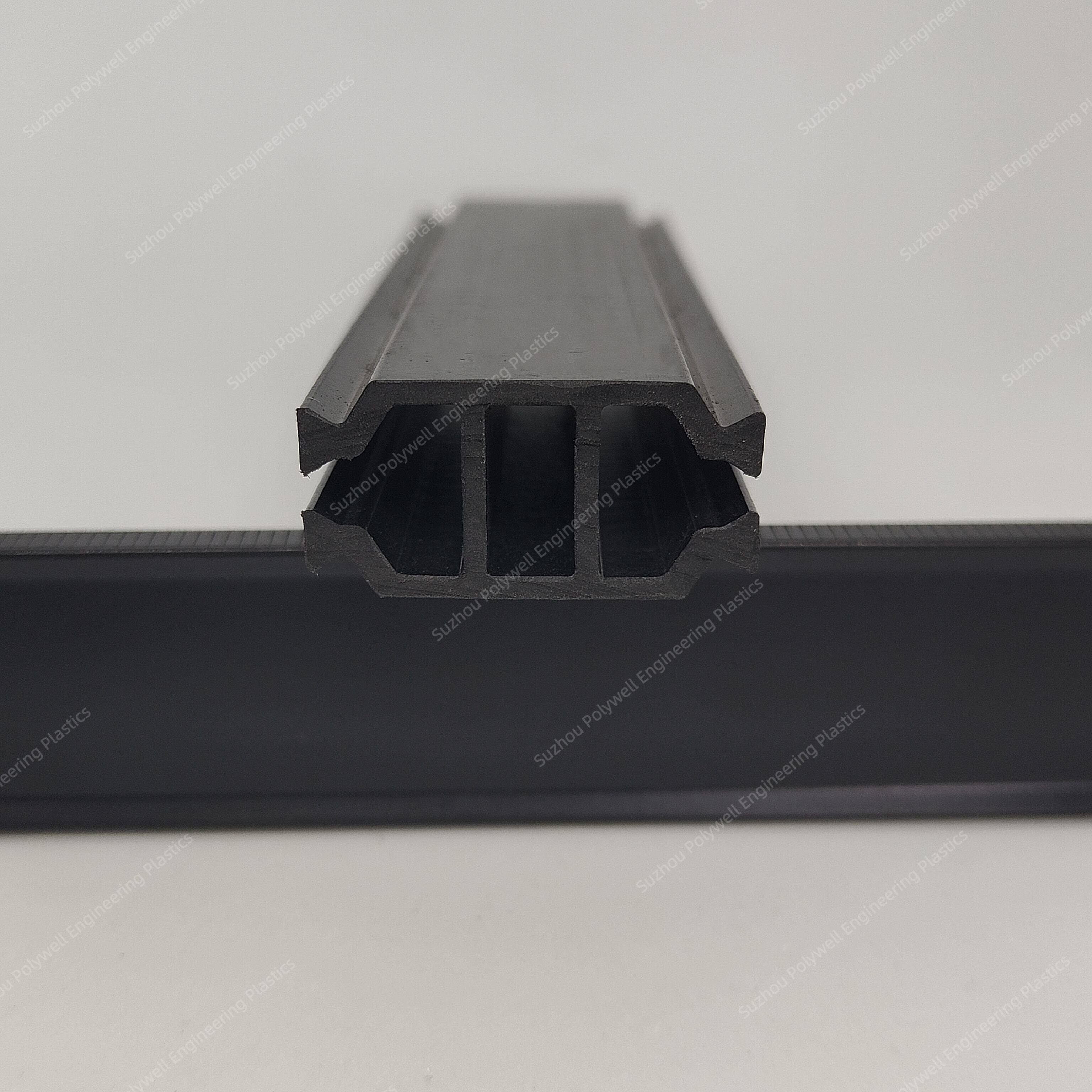

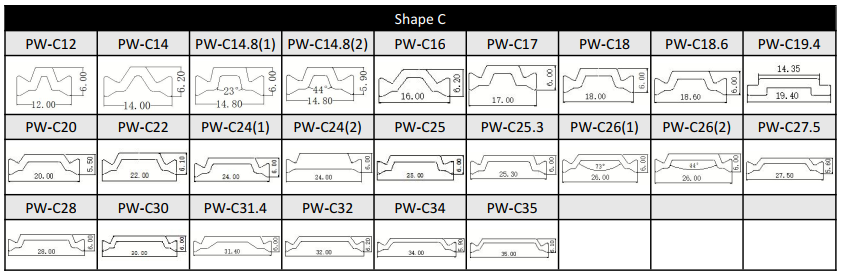

C-hom tsim muab txoj hauv kev ua kom sov ntev dua, ua rau muaj kev ua haujlwm zoo ntawm kev rwb thaiv tsev zoo dua li I-hom sawb, thaum tseem muaj peev xwm ua tau ntev ntev. Tsis tas li ntawd, C-hom PA sawb kuj yog ib qho tsim nyog rau kev tso dej tawm ntawm cov pas dej ua ke thermal tawg.

Rau C-hom sawb, peb tuaj yeem muab qhov loj me hauv qab no lossis kho raws li tus neeg siv khoom kos duab.

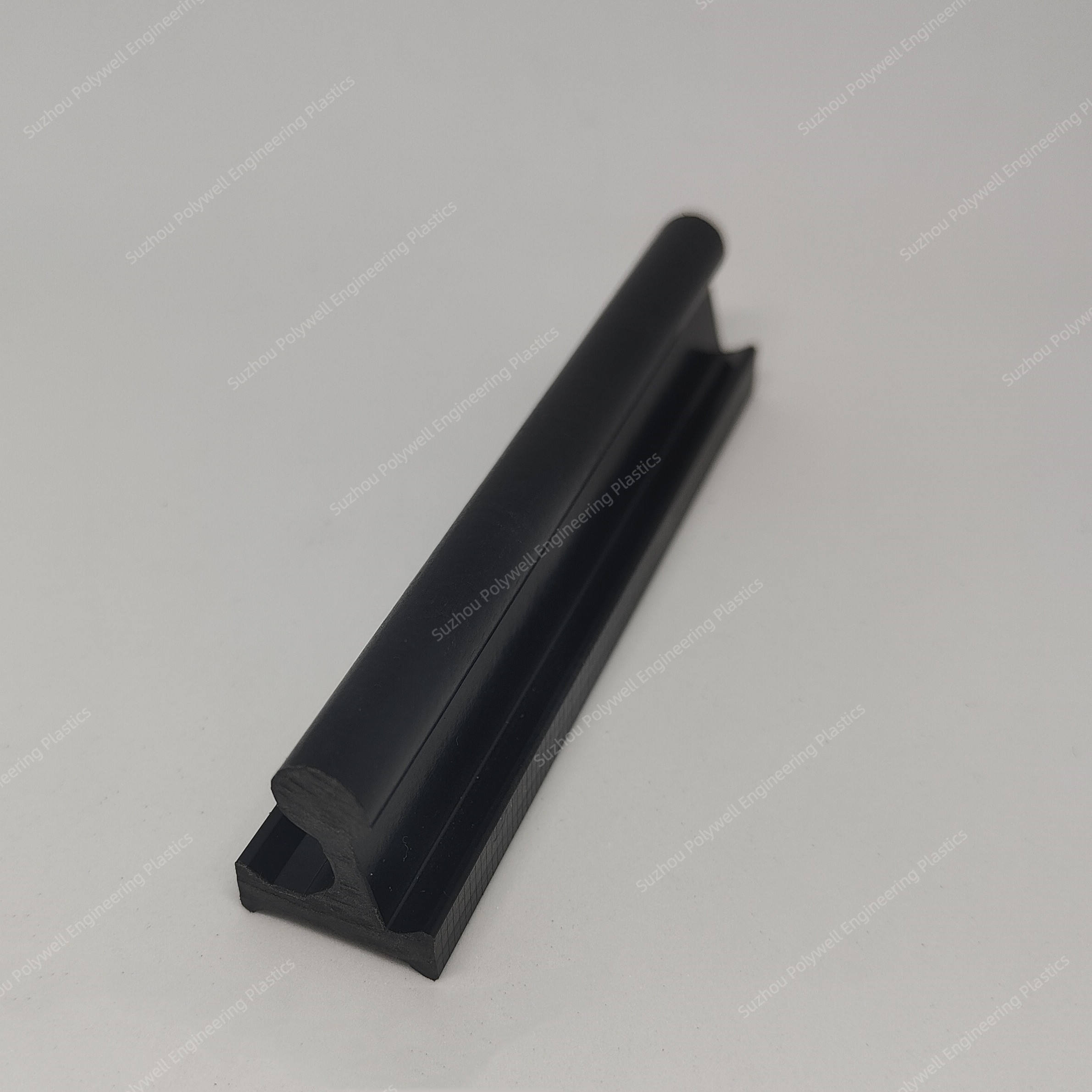

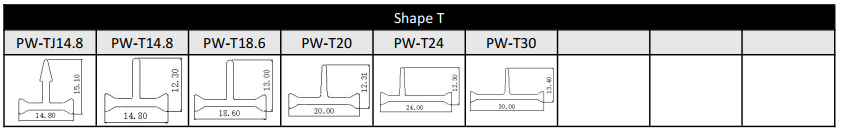

Cov qauv tsim ntawm T-hom thermal so strips feem ntau suav nrog ntu kab rov tav thiab ntu ntsug, tsim "T" - zoo li tus qauv.

Qhov kev tsim no ntxiv ib qho me me nyob rau hauv lub thermal so strip, tso cai rau lub sealing strips sib tshooj nrog cov thermal so strips, yog li kev txhim kho tag nrho cov rwb thaiv tsev kev ua tau zoo.

Rau T-hom sawb, peb tuaj yeem muab qhov loj me hauv qab no lossis kho raws li tus neeg siv khoom kos duab.

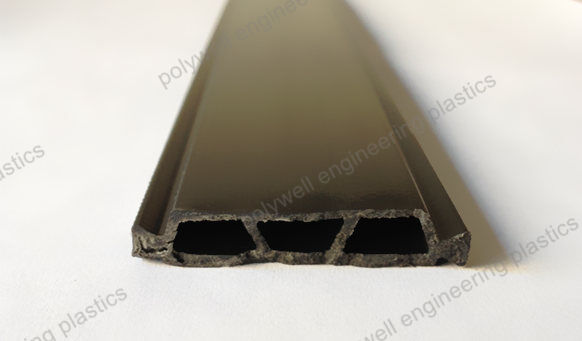

Hollow thermal so strip, tseem hu ua multi-cavity rwb thaiv tsev sawb, tuaj yeem txo cov cua sov hloov los ntawm kev hloov cov huab cua ntws, yog li ua tiav cov nyhuv rwb thaiv tsev thiab ntxiv kev txhim kho rwb thaiv tsev.

Hollow thermal so strip tam sim no yog cov khoom lag luam tseem ceeb hauv kev ua lag luam thiab tuaj yeem txhawb nqa qhov dav dav. Ntau cov thermal so strips nrog ib txoj kab uas hla ntawm 35mm los yog ntau tshaj nyob rau hauv kev ua lag luam yog ua rau ntau kab noj hniav, thiab lawv longitudinal load-bearing muaj peev xwm yog siab heev.

Rau cov hollow hom sawb, peb tuaj yeem muab qhov loj me hauv qab no lossis kho raws li tus neeg siv khoom kos duab.

Product Performance

Khoom |

Chav tsev |

GB/T 23615.1-2009 |

PW-Technical specification |

Qhov ntom |

g/cm3 |

1.3±0.05 |

1.28-1.35 |

Linear expansion coefficient |

K-1 |

(2.3-3.5)×10-5 |

(2.3-3.5)×10-5 |

Vicat softening kub |

ºC |

≥230 |

≥233 |

Melting point |

ºC |

≥240 |

≥240 |

Kev ntsuas tensile tawg |

- |

Tsis muaj kab nrib pleb |

Tsis muaj kab nrib pleb |

Ntug hardness |

- |

80±5 |

77-85 |

Kev cuam tshuam lub zog (tsis suav nrog) |

KJ/m2 |

≥35 |

≥38 |

Tensile zog (longitudinal) |

MPa |

≥80ib |

≥82ib |

Elasticity modulus |

MPa |

≥4500 |

≥4550 |

Elongation thaum so |

% |

≥2.5 |

≥2.6 |

Tensile zog (transverse) |

MPa |

≥70ib |

≥70ib |

High kub tensile zog (transverse) |

MPa |

≥45ib |

≥47ib |

Tsawg kub tensile zog (transverse) |

MPa |

≥80ib |

≥81ib |

Dej tsis kam tensile zog (transverse) |

MPa |

≥35ib |

≥35ib |

Kev laus kuj tensile zog (transverse) |

MPa |

≥50ib |

≥50ib |

1. Cov dej piv txwv tsawg dua 0.2% los ntawm qhov hnyav.

2. Kev kuaj mob ib txwm: (23 ± 2) ºC thiab (50 ± 10)% txheeb ze av noo.

3. Cov lus qhia tshwj xeeb uas cim "a" tsuas yog siv rau I-shape strip txwv tsis pub, cov lus qhia tshwj xeeb tau txiav txim siab ntawm tus neeg muag khoom thiab tus neeg yuav khoom los ntawm kev sib tham, yuav tsum tau sau rau hauv daim ntawv cog lus lossis kev yuav khoom.

EN

EN