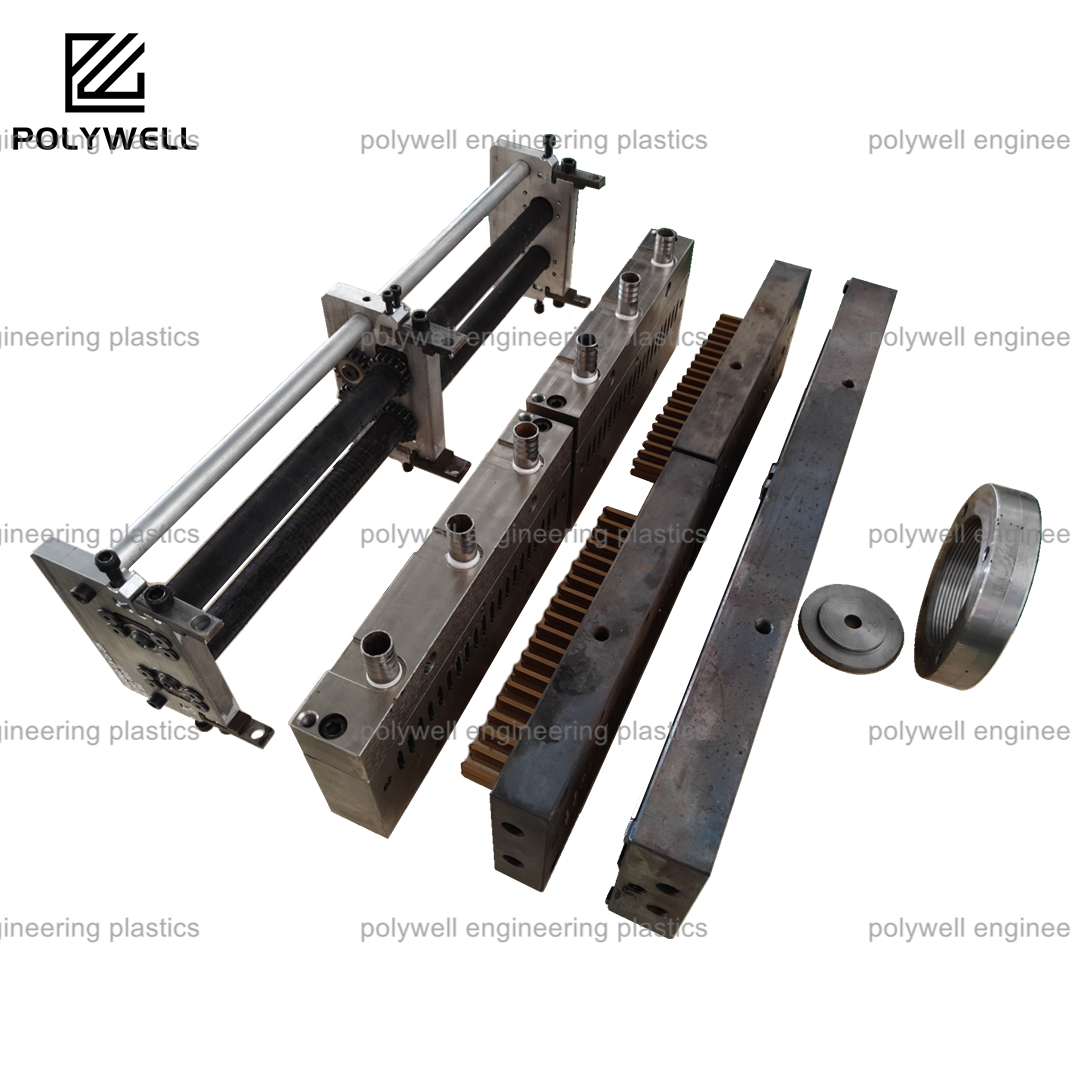

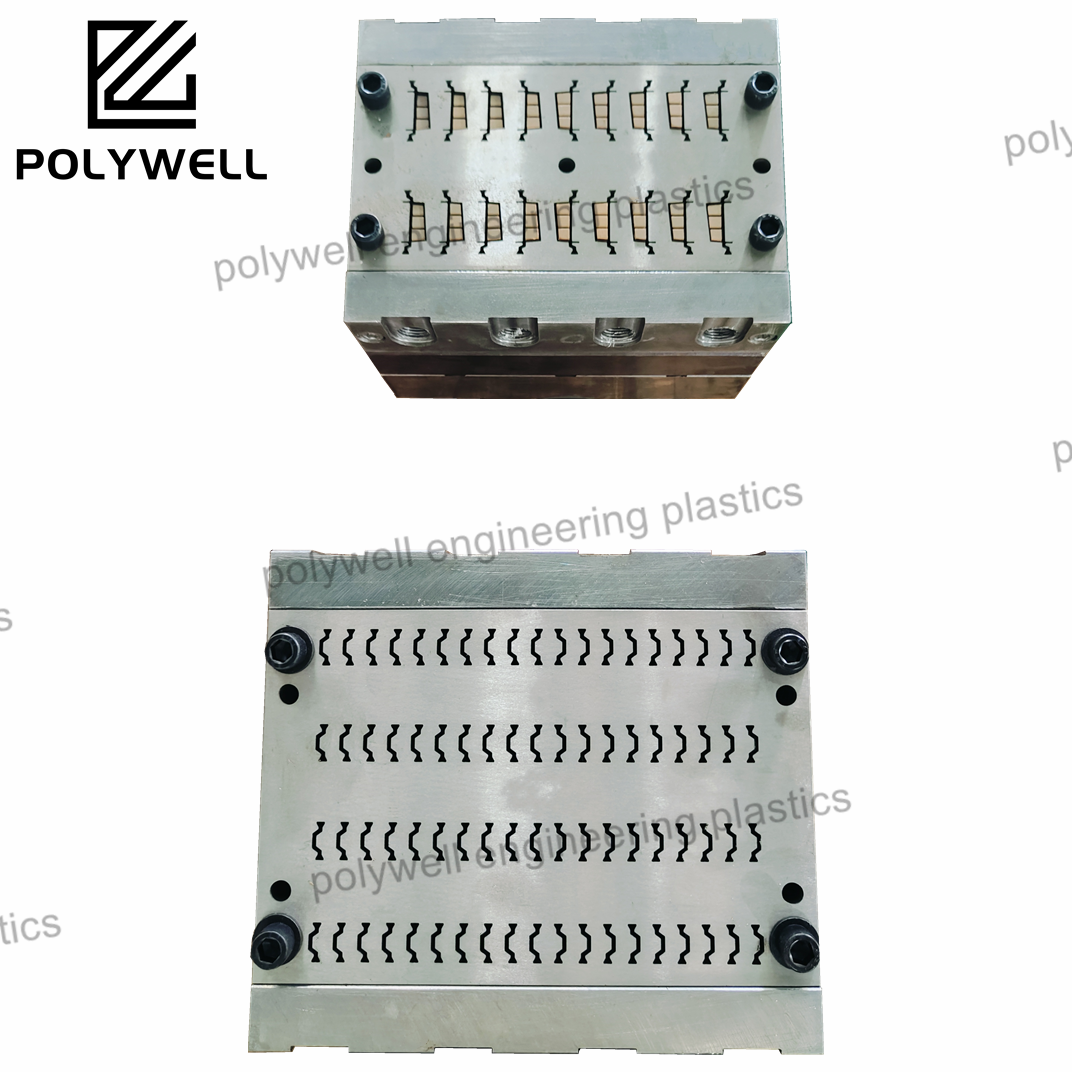

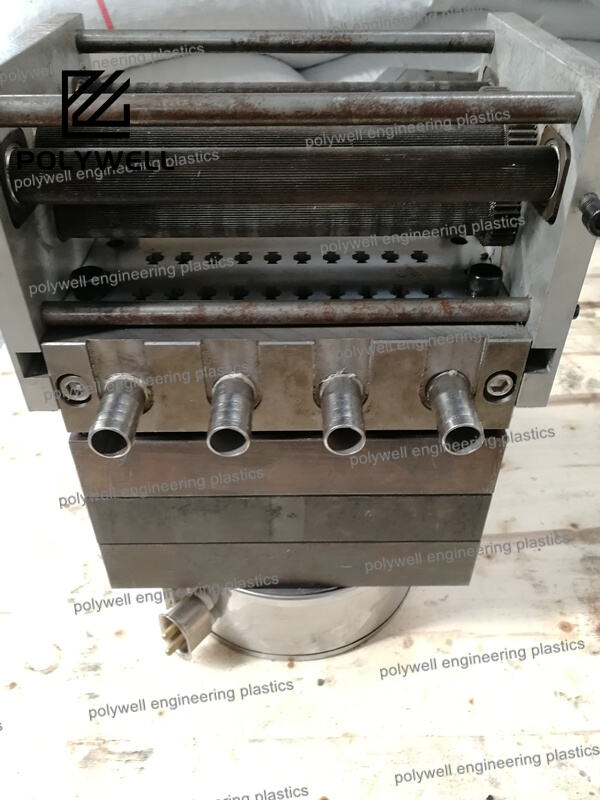

Qhau txwv roj teev muaj nuj nqi yog qhau tshuab tsim nyog rau tsim duv roj teev uas tsis yog sib npaug. Kev kho qhau yog qhj nyob ntawm kev tshuaj xyuas dej thiab kev tshuaj kawm, uas xav kom pauv roj los ntawm qhov chaw tsim roj mus rau ib qhov sib npaug, duv pla saum. Qhov kev pheej hmoo yog kom txoj kab roj tso tseg zoo ib yam rau tag nrho qhov ntxoos ntawm qhau. Vim tias roj teev yuav tsum dhau los ntawm qhov chaw thiab qhov dav sib txawv mus rau qhov chaw sib txawv ntawm qhov ntxoos, qhov hauv qab ntawm qhau, lossis qhov chaw roj tshout, yog tsim los kom sau qhov roj tshout rau qhov chaw tsim nyog thiab pab roj tshout mus rau qhov chaw nyuaj mus. Qhov no hu ua kev daws roj tshout. Qhau feem ntau muaj ntau qhov plhaub hlwb hlwb los ntawm hlwb, txhua qhov muaj kev kho tshuab rau qhov chaw roj tshout thaum tshuab tseem ciaj. Qhov tom nian, qhov teb chaws, muaj qhov ntsiag kev pab kom roj tshout nyob ib yam thiab tswj xyuas qhov siab taw tes tso tseg. Qhau kuj tsum xav txog qhov siab dua, qhov uas roj tshout hla tom qab tso tseg qhau, thiab qhov roj teev hla tom qab ntxuav. Rau cov khoom siv li PVC, ABS, lossis Polyolefins, qhau kev kho yuav sib txawv ntau ntawm qhov kev sib piv ntawm khoom. Qhau tsim los ntawm hlwb hlwb zoo tshaj plaws, hlwb hlwb kom tsis tu, thiab muaj kev tswj xyuas teb chaws meej meej siv roj teev thiab thermocouples kom tswj xyuas qhov siab zoo tshaj plaws thiab sib xws rau kev tsim khoom zoo.