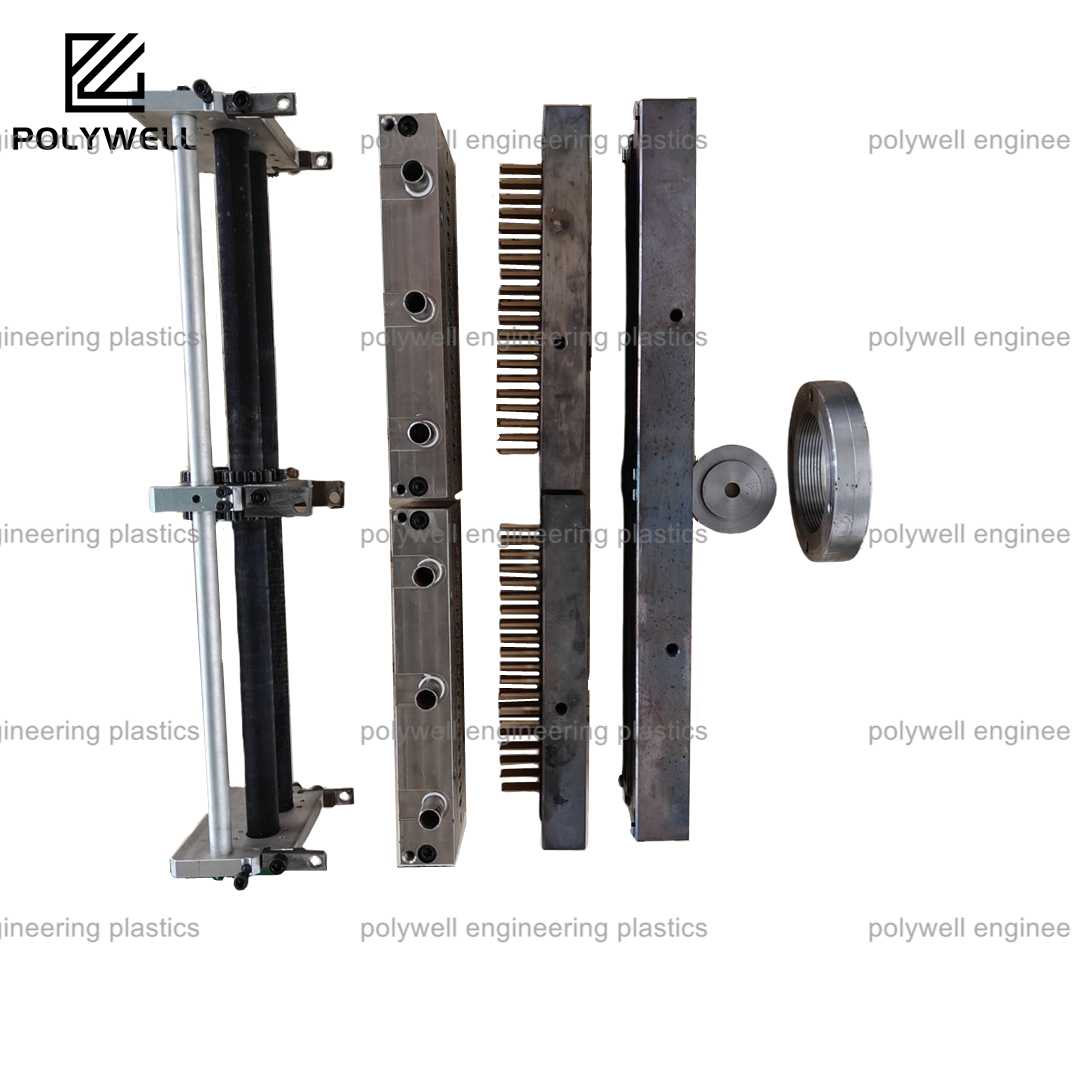

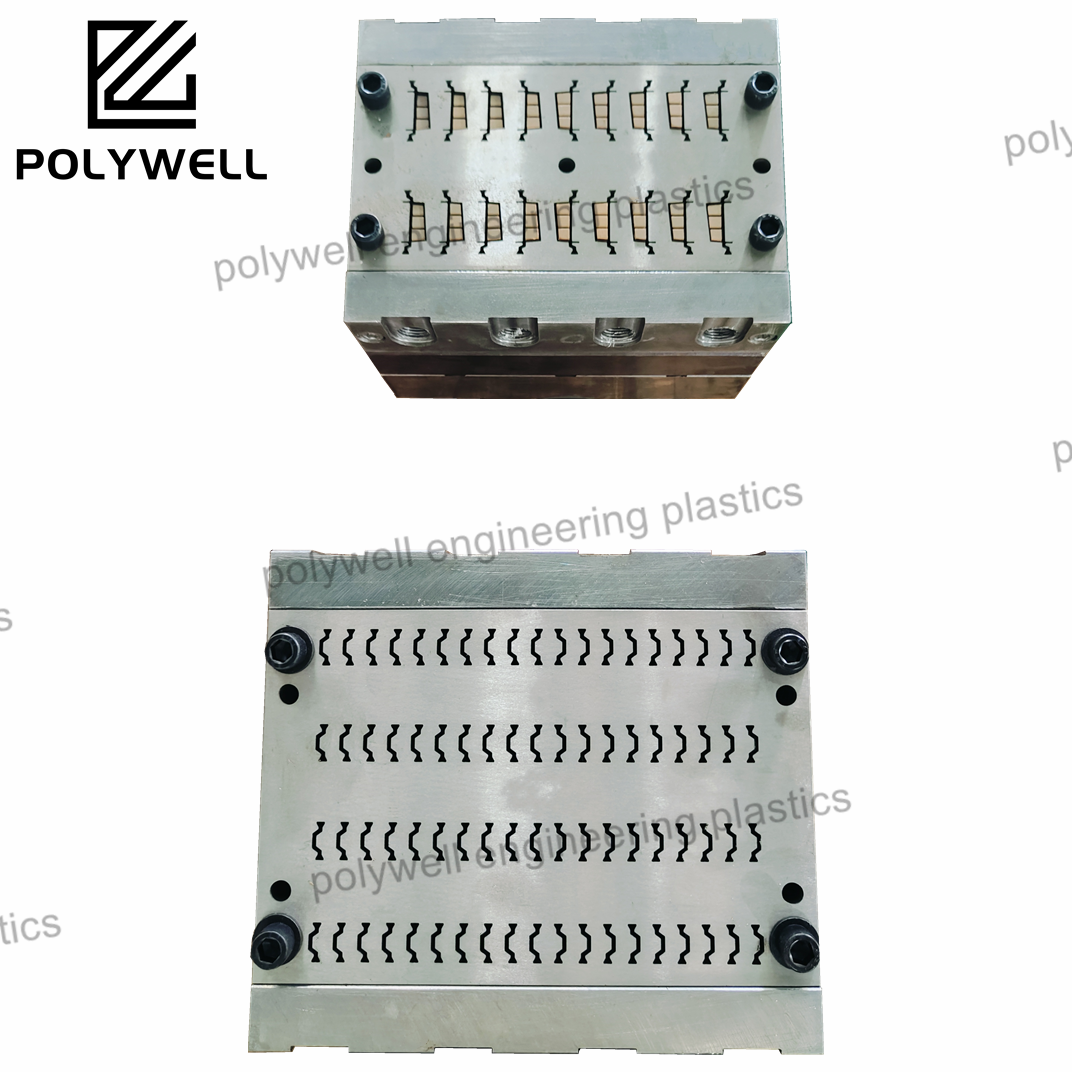

Qhau khoom lag luam kho siv yog qhov chaw tsim khoom uas muaj feem ntau tshwj xeej rau kev tsim kho kom raug rau cov kev siv khoom tshwj xeej rau txhua hom kev siv. Kev pab cuam yuav pib los ntawm kev soj ntsuam cov lwm yam xav tau, suav nyob rau hauv kev tshawb nrhiav cov kev tsim nyog rau kev siv zav kub, kev sib tham nrog dej thiab av, kev nco nwg rau cov luj lawm, thiab cov xav tau rau saum npoo. Kev xaiv yas yog qhov tseem ceeb tshaj plaws, uas cov neeg tsim khoom yuav tsum tshawb nrhiab ntau dua mil yas thiab cov khoom siv los xaiv tus yas uas zoo tshaj plaws rau kev tsim khoom, suav nyob rau hauv zav kub, kev ua kom zoo, kev tiv thaiv dej thiab khoom siv, kev nyob siab ntawm li cas, thiab ntau dua lwm yam. Lub sijhawm tsim khoom yuav tsum rau cov khoom tsim nyog, siv cov lus tshwj xeej rau kev tsim khoom, xws li kev tsim lub ntsiab cai zoo ib yam, kev tsim lub tog raj, thiab kev tsim cov rooj caij. Kev xaiv kev tsim khoom yuav nyob ntawm lub sijhawm tsim khoom, qhov loj ntawm khoom, thiab qhov yooj yim ntawm yas, suav nyob rau hauv kev tsim khoom los ntawm kev ntxig yas rau kev tsim khoom ntau, CNC machining rau kev tsim khoom nug thiab tsim khoom me me, lossis kev tsim khoom los ntawm kev ntxig yas rau kev tsim khoom loj thiab meej. Kev tsim khoom tshwj xeej yuav tsum muaj ntau nuj nqaij, uas cov neeg tsim khoom yuav tsum tshawb nrhiab kev ntxig yas, kev sov, thiab kev tso khoom tawm kom zoo. Kev daws tshaj tawm yuav tsum muaj kev soj ntsuam thawj zaug, kev daws tshaj tawm tshiab, thiab kev soj ntsuam ntau yam kom paub seeb tias khoom tsim nyog zoo, muaj zav kub, thiab tuaj meem. Kev tsim khoom kho siv yuav tsum muaj kev sib pab zoo ntawm neeg sau khoom thiab neeg tsim khoom tag nrho lub sijhawm, los ntawm kev tshuaj xyuas mus rau kev tsim khoom ntau. Cov neeg tsim khoom tshwj xeej yuav muaj kev pab ntau dua xws li kev sib koom tes, kev sau npe, kev nres khoom, thiab kev daws tshaj tawm kev lag luam. Qhov tshwm sim yog khoom tsim nyog uas muaj zav kub thiab zoo tshaj plaws rau kev siv, thiab muaj kev pab hauv kev lag luam los ntawm kev ruaj khov khoom, kev leej li cas, thiab kev ua kom meej.