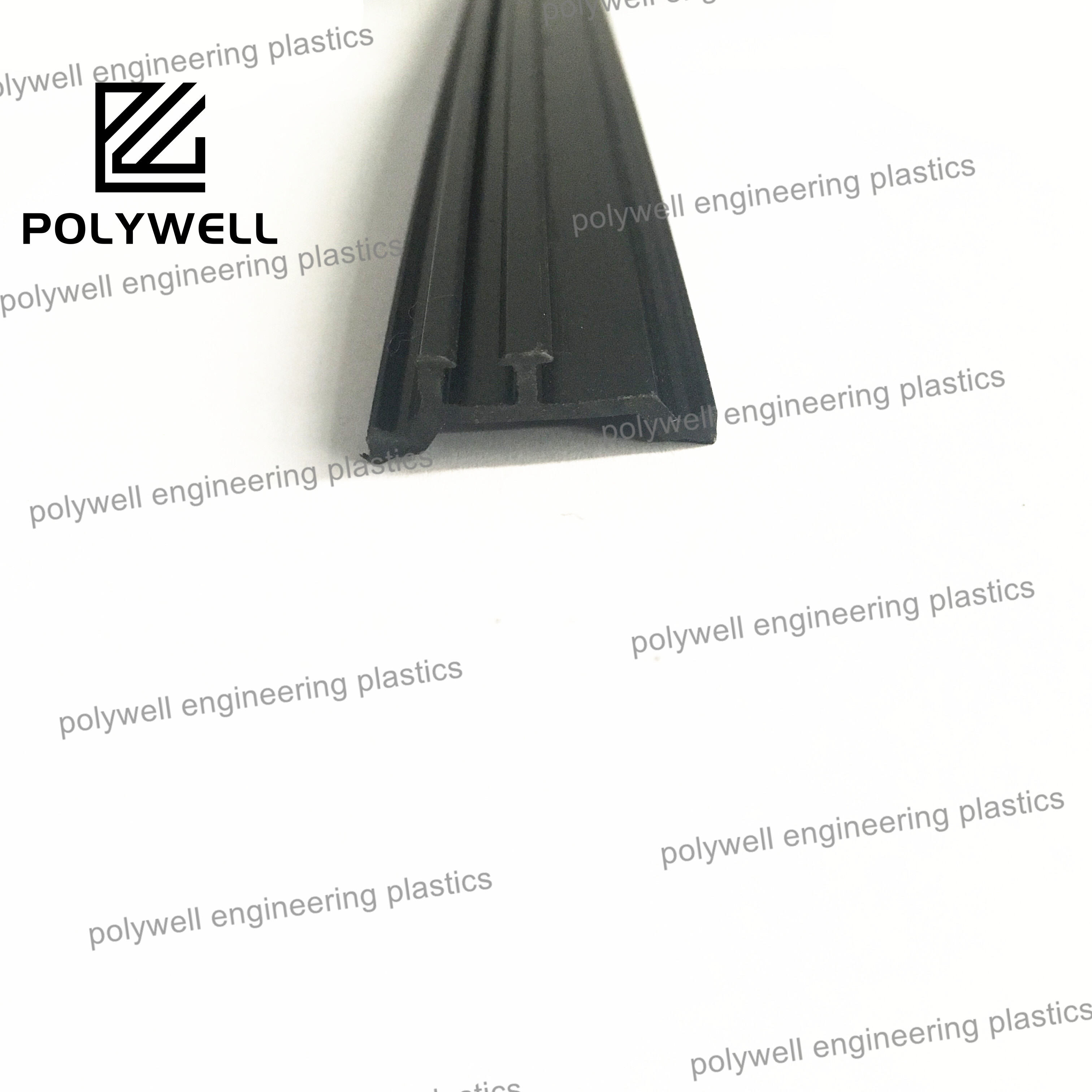

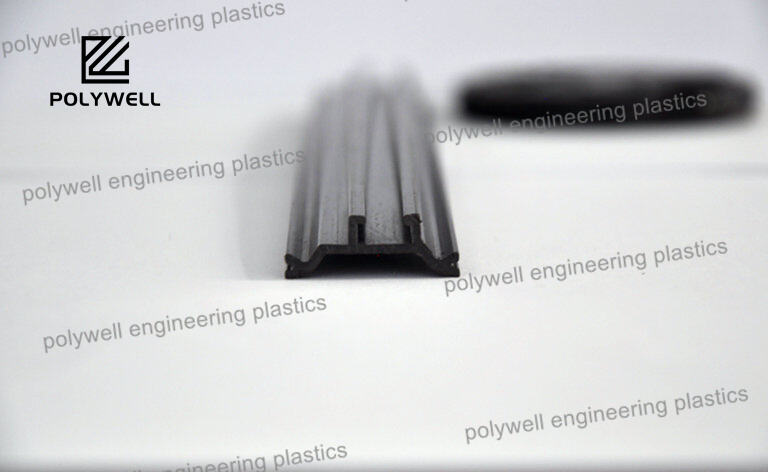

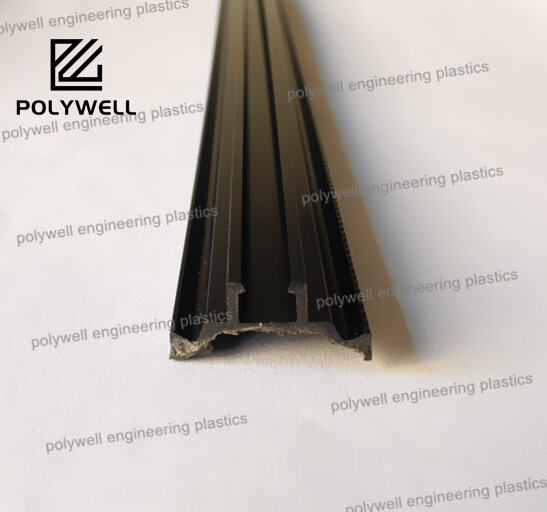

Daim npau ntawv PA, txhais tau tias yog daim npau ntawv tsim los ntawm Polyamide (Nylon), yog qhov chav koom tes uas muaj nuj nqi tshaj plaws rau kev siv tshwj xeeb rau kev tsim khoom tshwj xeeb, nyob zoo heev hauv kev pab cuam, kev tiv thaiv kom tsis txag, thiab kev nyob siab hauv kawg. Txawm hais tias Polyamide 6 thiab PA 66 yog cov khoom siv tshaj tshwv tshaj plaws, tiam sis cov daim npau ntawv no feem ntau tsis siv raw, tsis muaj kev txhim kho, rau kev siv hauv qab zib vim tias lawv muaj kev nyob nrog dej thiab kev hloov chaw. Thaum li cas los xij, lawv feem ntau raug siv nrog cov khoom kho, tshaj tshwv yog cov sib thooj hlwb, kom tsim tau cov hom PA66 GF30, uas tso cai rau kev txhim kho kev pab cuam, kev nyob ncig, thiab kev nyob siab hauv kawg. Kev tsim daim npau ntawv PA feem ntau ua tiav los ntawm kev tsim khoom los ntawm kev tshuab, qhov twj tso cai rau thermoplastic compound raug ntxuav mus rau qhov chaw ntxuav thiab tso tawm los ntawm qhov chaw tshuab kom tsim tau daim npau ntawv muaj rau tib lub sijhawm thiab muaj qhov chaw tshuab tib yam. Qhov kev tsim no pab tsim tau cov daim npau ntawv muaj kev tshwm sim tshaj tshwv, xws li cov daim npau, cov kab ro, cov tub, thiab cov chaw tshuab tshiab tsim rau kev siv tshwj xeeb xws li cov daim npau ntawv tiv thaiv kawg rau hauv pa, thiab lwm yam. Cov qhov tshwj xeeb uas pab PA npau ntawv siv tau zoo hauv kev siv tshwj xeeb yog qhov tshwj xeeb ntawm kev sib piv zoo ntawm kev tiv thaiv kawg (ntxuav dav hlau ~0.3 W/m·K rau cov khoom siv sib thooj hlwb) thiab kev pab cuam heev. Lawv muaj kev tiv thaiv zoo tsha, khoom siv xws li neeg thiab solvents, thiab kev nyuaj siab, kom paub tseeb tias lawv tuaj yeem siv ntev hauv kev siv tshwj xeeb. Tab sis, yuav tsum xav ntau txog kev nyob nrog dej; yuav tsum ntxuav dej dhau tom qab tsim khoom, thiab hauv kev siv, yuav tsum xav txog kev hloov chaw dhau tom qab nyob nrog dej. Nyob ntawm kev tsim khoom, PA npau ntawv tsis tuaj yeem siv tau hauv kev tsim khoom tshwj xeeb xws li cov guide rails thiab seals, hauv kev tsim khoom rau cov daim npau ntawv thiab gears, thiab hauv cov khoom siv tshaj tshwv. Lawv kev siv tshwj xeeb, ntxiv rau kev siv tshuab tshwj xeeb, ua rau lawv yog qhov tseem ceeb hauv kev tsim khoom tshaj tshwv, kom muaj qhov kev daws teeb meem uas tsis tuaj yeem siv metal vim tej teeb meem xws li corrosion, ntau, lossis thermal bridging.