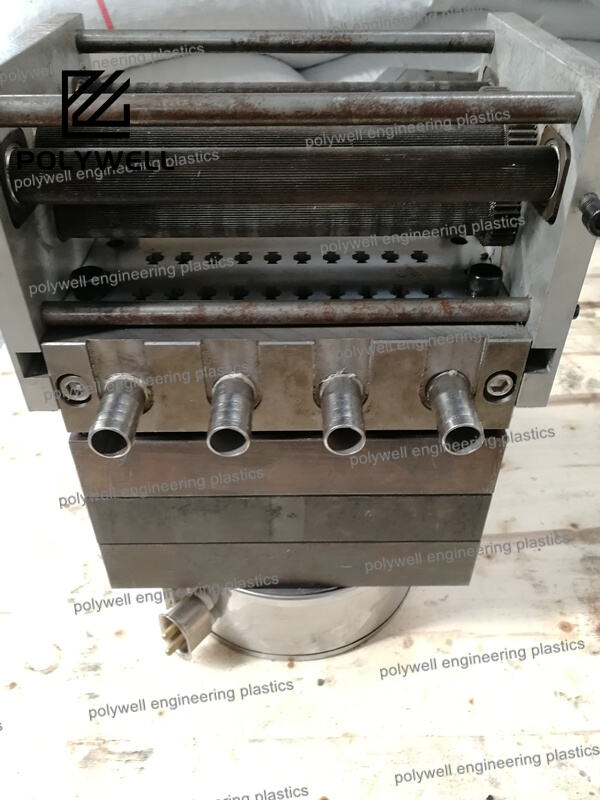

Kev tsim kho tshuab ntxig, thaum nyob hauv American English qhov chaws uas "mold" yog sau nrog ib feem 'o', no txhais tau tias kev tsim kho cov tshuab rau kev tuag tshuab los ntawm kev ntxig lossis kev ntxig tshuab. Qhov kev paub no xav tau kev paub ntau yam thiab sib txawv xws li kho mob dej, kho mob kub, thiab kho tshuab. Kev tsim kho nyem pib los ntawm kev suv xwm ntau txog daim duab ntawm khoom, nrhiav cov ntaub ntawv uas xav tau tshuab tshwj xeeb xws li side-cores rau cov nqaj lossis collapsible cores rau cov rooj sab nraud. Kev tsim kho cov tshuab sov yog tseem ceeb, muaj sprue, runners, thiab gates uas raug tshwj xeeb rau cov ntaub uas raug sawv cev—yog li metal ntxuav rau die casting lossis polymer rau injection molding. Kev kho tshuab cooling systems siv cov rooj kawg uas raug teeb tsa kom cuam tshwms siab txog kev sib txuas kub, muaj cov lus nug tshwj xeeb rau kev tshem tawm kub kom ua tiav lub sijhawm thiab kev ntsuas meej. Kev tsim kho cov tshuab tshem tawm tsum tshem tawm cov zog tshuab tshwj xeeb thaum tiv thaiv tsis pub muaj kev puas tsuaj, muaj pins, sleeves, thiab stripper plates teeb tsa nyob rau qhov chaw tshwj xeeb. Rau cov duab ntau yam, ntau tshuab ntxiv xws li lifters, sliders, thiab unscrewing devices raug sib xyeeb nrog cov tshuab tshem tawm tshwj xeeb. Kev xaiv ntaub ntawv tshuab hla rau tool steels uas muaj qhov tshwj xeeb sib xws rau qhov kev siv—kev tiv thaiv thermal fatigue rau die casting, kev tiv thaiv kev puas tsuaj rau cov ntaub puas tsuaj, thiab kev tshem tawm zoo rau cov saj ntxos zoo. Cov kev tsim kho die mold hluas siv software simulation kom suv xwm txog kev sib thooj, kev sov kub zoo, thiab kev ntsuas meej nyob rau hauv qhov kev siv. Lub tshuab tsim kho tseem tsum tso siab rau kev kawg kub, muab cov av tshem tawm kom av tshem tawm, thiab tshuaj xyuas kom zoo dua txhua lub sijhawm tshuab siv. Kev tsim kho venting tiv thaiv kev tshem tawm av uas tshaj tawm kev puas tsuaj, thaum alignment systems tshuaj xyuas kev ntsuas meej nyob rau hauv kev siv ntau zog. Qhov kev tsim kho die mold zoo tshaj plaws yuav muab cov kev tuag tshuab uas tuaj yeem tuag khoom zoo, muaj kev ntsuas meej thiab saj ntxos zoo, thaum siv tau ntau dua ob hlis ntawm kev siv.