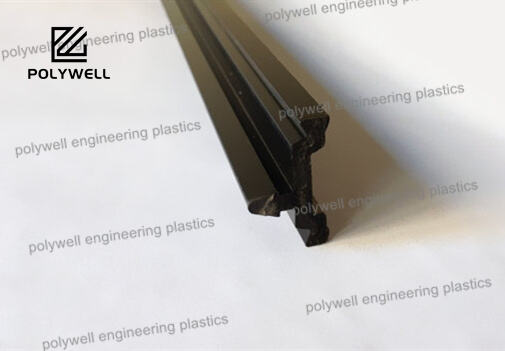

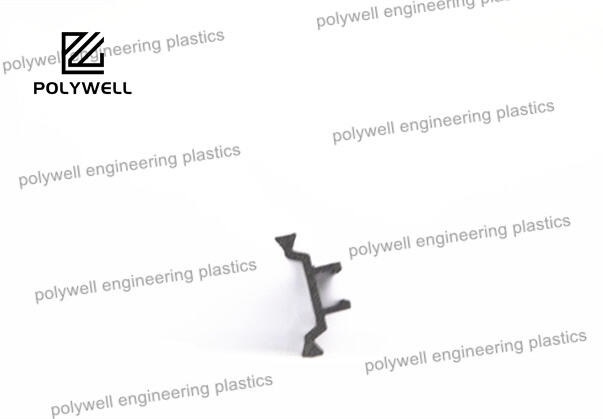

A thermal barrier, in the context of building construction and industrial design, is a component or system specifically engineered to significantly reduce the transfer of heat energy between two environments. Its primary purpose is to enhance energy efficiency, improve occupant comfort, and prevent problematic condensation. In architectural applications, the most critical thermal barriers are those that address thermal bridging—localized areas in the building envelope where heat flows more readily, such as through metal window frames or structural connections. Here, the thermal barrier is physically embodied as a strip of material with low thermal conductivity, typically a glass-fiber reinforced polyamide (like PA66 GF30), that is inserted within an aluminum or steel profile. This "barrier" physically separates the interior and exterior metal sections, dramatically reducing heat flow and raising the temperature of the interior frame to prevent condensation. The effectiveness of this barrier is quantified by its contribution to lowering the U-value and Psi-value of the assembly. Beyond fenestration, thermal barriers are also integral in walls, roofs, and floors, where bulk insulation materials like mineral wool or foam boards create a resistive layer. In a broader sense, any material or assembly that imposes a high level of thermal resistance between a heat source and a heat sink can be considered a thermal barrier, making the concept fundamental to sustainable design, energy conservation, and the creation of comfortable, durable, and mold-free built environments.