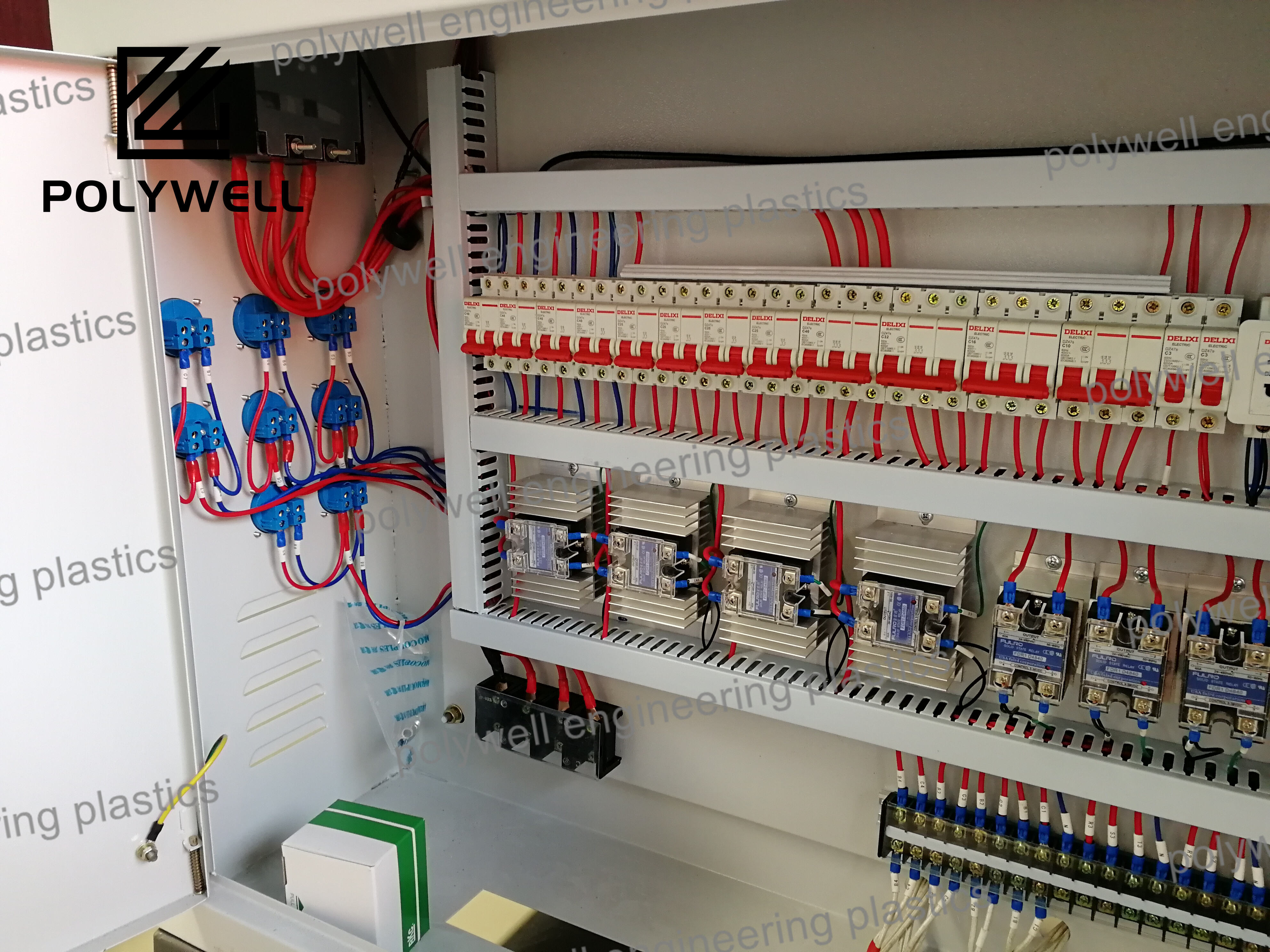

The PVC single screw extruder represents a specialized variation of extrusion equipment engineered specifically for processing polyvinyl chloride compounds, which present unique challenges including thermal sensitivity, corrosive degradation products, and complex flow behavior. These machines feature screws with compression ratios typically between 1.8:1 and 2.5:1, carefully designed to gradually melt PVC powders without creating excessive shear heat that could cause degradation. The barrel is constructed from dual-layer bimetallic alloys with exceptional corrosion resistance to withstand hydrochloric acid formation at processing temperatures. Temperature control systems employ multiple precisely calibrated zones with liquid cooling capabilities to maintain thermal profiles within narrow windows, typically 160-210°C depending on compound formulation. Feed sections are specifically designed to handle the poor flow characteristics of PVC powders, often incorporating grooved bushings and forced feeding mechanisms to ensure consistent material intake. Screw designs may include mixing elements such as Maddock-type mixers or blister rings to achieve homogeneous melt temperature and pigment dispersion. Downstream equipment integration is critical, with calibration tables, vacuum sizing tanks, and haul-offs specifically configured for PVC profiles, pipes, or sheet products. Safety systems include emergency stop mechanisms, barrel temperature overtemperature protection, and amperage monitoring to detect potential screw seizure. Modern PVC extruders incorporate sophisticated control systems with recipe management for different compound formulations, data logging for quality traceability, and remote troubleshooting capabilities. Processing considerations include meticulous purging procedures during material changes, regular inspection of screw and barrel for wear, and adherence to strict thermal profiles to prevent degradation. The versatility of these machines allows processing of both rigid and flexible PVC formulations across construction, medical, and automotive applications, though each requires specific screw geometries and processing parameters to optimize output quality and production efficiency.