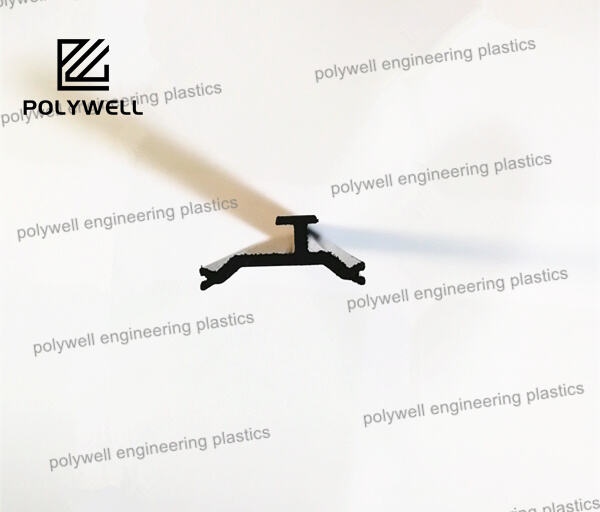

To prevent thermal bridging is to adopt a holistic design and construction strategy aimed at eliminating or significantly mitigating paths of high heat flow through the building envelope. Thermal bridging occurs where materials with high thermal conductivity, such as aluminum, steel, or concrete, penetrate or bypass the insulation layer, creating localized areas of energy loss and cold surfaces. Preventing these bridges is paramount for achieving energy efficiency, occupant comfort, and building durability. Key strategies include the use of thermally broken window and door frames, where a polymer strip interrupts the metal frame; installing structural thermal breaks at balconies, parapets, and other structural connections that project through the insulation layer; ensuring continuous insulation (ci) without gaps or compression; and careful detailing at junctions like wall-to-floor and wall-to-roof connections to maintain the insulation barrier. Advanced modeling tools, such as thermal simulation software, are used to identify and analyze potential bridges during the design phase. By systematically preventing thermal bridging, buildings can achieve significantly lower U-values, reduce condensation risk, minimize heating and cooling demands, and create a more comfortable, healthy, and sustainable indoor environment, ultimately leading to lower operational costs and a reduced carbon footprint.