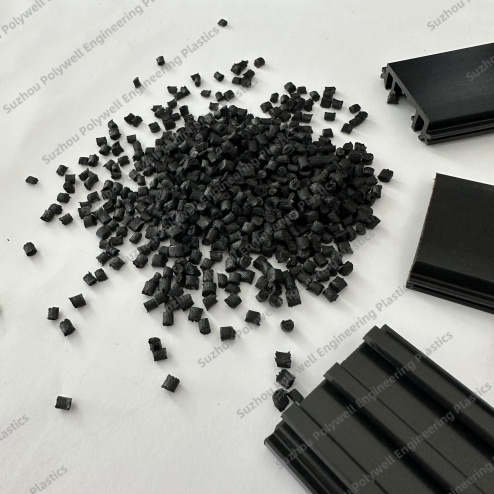

Within the family of polyamide materials, PA66 (Polyamide 66) stands as the industry benchmark for high performance thermal break strips, and it is a core focus of our material expertise. PA66 GF25, a grade reinforced with 25% glass fiber, is particularly valued for its superior mechanical properties, including high tensile strength, stiffness, and exceptional resistance to creep—the tendency of a material to deform under sustained mechanical stress. This is critical for ensuring that windows and doors continue to operate smoothly and support their own weight over decades of use. Furthermore, PA66 possesses a high melting point, typically around 260°C, which allows it to retain its structural integrity in a wide range of climatic conditions, from freezing winters to scorching summers. Its low coefficient of thermal expansion is relatively close to that of aluminum, which minimizes stresses at the critical metal to plastic interface during temperature fluctuations. Our proficiency lies not just in sourcing high quality PA66, but in compounding and processing it to perfection. We understand the precise drying requirements, melt temperature profiles, and screw design needed to process PA66 without degrading its molecular structure, thereby preserving its innate toughness and excellent insulation properties. By offering a complete solution that encompasses both the material and the production technology, we ensure that our clients can reliably manufacture thermal breaks that consistently prevent thermal bridging and contribute to energy efficient building envelopes worldwide.