-

Thermal Break Strip

-

Polyamide Nylon 66

-

Glass Filled Nylon 66

-

Broken Bridge Aluminum Window

-

Plastic Moulding Dies

-

Nylon Extruder Machine

-

Single Screw Extruder

-

Pipe Production Line

-

Plastic Extrusion Machine

-

Aluminum Cutting Machine

-

Plastic Granulator Machine

-

Tensile Testing Machine

-

Laser Code Printer

-

Water Bottling Machine

-

Mr. Paolo CelaniThank you very much for very good news! We appreciate your honesty and collaboration. You have supplied good dies, all sizes within tolerance. We have ordered dies for a total amount of more than 200,000 USD and we are continuing to order. Thank you again to you and your very professional team.

Mr. Paolo CelaniThank you very much for very good news! We appreciate your honesty and collaboration. You have supplied good dies, all sizes within tolerance. We have ordered dies for a total amount of more than 200,000 USD and we are continuing to order. Thank you again to you and your very professional team. -

Mr. Martyn HainesThank you for your help with this order and if ever you need someone to tell customers how helpful you are just tell them to contact me.

Mr. Martyn HainesThank you for your help with this order and if ever you need someone to tell customers how helpful you are just tell them to contact me. -

Mr. Dietmar DürrI received your samples. I agree to Mr. Wölki, they looks pretty good. We will arrange the balance payment. Please pack the mold and send them asap.

Mr. Dietmar DürrI received your samples. I agree to Mr. Wölki, they looks pretty good. We will arrange the balance payment. Please pack the mold and send them asap.

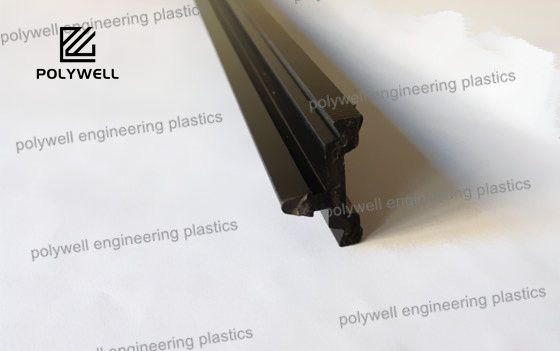

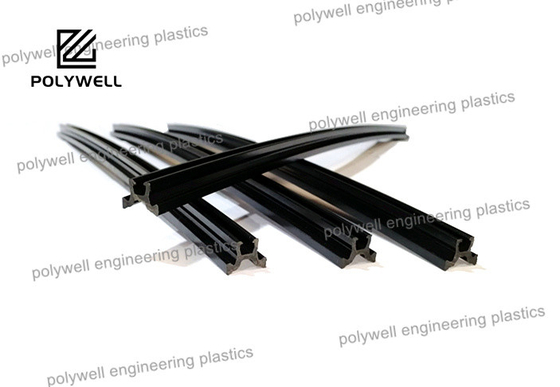

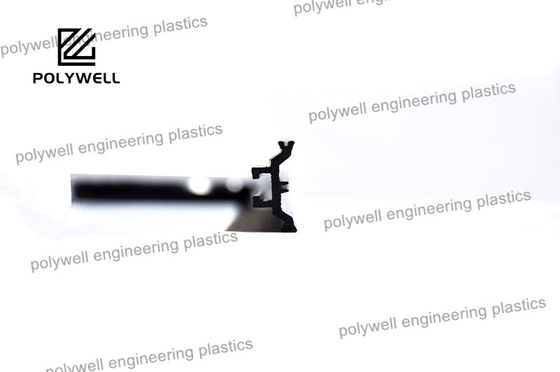

Black Polyamide Thermal Break Strips For Aluminium System Profile Heat Insulation

| Place of Origin | China |

|---|---|

| Brand Name | Polywell |

| Certification | SGS |

| Model Number | PW-CT |

| Minimum Order Quantity | 5000 Meters |

| Price | USD 150-220 per Square Meter |

| Packaging Details | Liner or Roll |

| Delivery Time | 15-20 Working Days |

| Payment Terms | 50% T/T before production, 50% T/T before delivery |

| Supply Ability | 100000 Meters per Day |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| OEM Service | Available | Customized Laser Printing | |

|---|---|---|---|

| Appication | Thermal Break Aluminum Windows And Doors | Plastic Modling Type | Extrusion |

| Origin | Zhangjiagang, China | DSC Melting Peak Temperature | 230-255℃ |

| Density | 1.25-1.35 G/cm3 | Port | Shanghai |

Product Description:

Thermal Break Profile is a special strip designed for sound insulation and thermal break purpose. It is available in various sizes, ranging from 10mm to 50mm in length, and the density of the product is 1.25-1.35 G/cm3. It is made from high quality materials, which can provide extra protection from heat and sound. Its unique design also helps to reduce energy consumption. It is a great choice for any sound insulation or thermal break application. Each piece of Thermal Break Profile is 6 meters in length, and the package is designed for safe transportation, either in plywood cases or on pallets. The origin of the product is Zhangjiagang, China.

Thermal Break Profile is a great option to improve sound insulation and thermal break performance. It can effectively reduce sound transmission and energy consumption. Its unique design also ensures excellent thermal performance. It is an ideal choice for any sound insulation or thermal break application.

Technical Parameters:

| Property | Description |

|---|---|

| OEM service | Available |

| Customized Laser Printing | |

| Origin | Zhangjiagang, China |

| Color | Black |

| DSC melting peak temperature | 230-255℃ |

| Length | 6 Meters per piece |

| Specification | 10-50mm |

| Size | Customized |

| Density | 1.25-1.35 G/cm3 |

| Port | Shanghai |

| Material | Thermal break strip, heat insulation bars, building material |

Applications:

Polywell's PW-CT and IT thermal break profile is a versatile PA66GF25 profile designed for use in thermal break aluminum windows and doors. The product has been certified by SGS and is available with both liner and roll packaging. It is offered in custom laser printing and with OEM service available. The minimum order quantity is 5000 meters, and the price is open for negotiation.

Polywell's thermal break profile is made from a unique combination of heat insulation bars and polyamide strip, providing excellent thermal insulation properties while maintaining strength, flexibility, and durability. The product is manufactured through extrusion plastic modeling and is able to withstand extreme temperatures and weather conditions. Polywell is able to produce up to 600,000 meters per month, with delivery taking place within 15 working days after payment.

Polywell's PW-CT and IT thermal break profile is an ideal solution for those looking to improve the energy efficiency of their windows and doors. It is manufactured with the highest level of quality control and is made from environmentally friendly materials. With the added benefits of quick delivery, custom laser printing, and OEM service, Polywell's thermal break profile is the perfect choice for those looking to keep their homes comfortable and energy efficient.

Customization:

Polywell's Thermal Break Profile is a building material that is used to reduce heat transfer between two elements. It is made of high-quality extrusion plastic and is available in various sizes, ranging from 10-50mm. Our Thermal Break Profiles are designed to provide maximum thermal insulation with minimal additional weight.

The Thermal Break Profile offered by Polywell is certified by SGS and meets the highest quality standards. You can customize your order with laser printing, and we guarantee a minimum order quantity of 5000 meters. Our prices are negotiable and delivery time is usually within 15 working days.

We are based in Zhangjiagang, China, and our supply ability of Thermal Break Profiles is up to 600,000 meters per month. We accept payment by T/T (50% before production, 50% before delivery). Our products can be packaged in liners or rolls.

![]()

Support and Services:

We offer technical support and service for our Thermal Break Profile product. Our team of experts are available to answer any questions and provide assistance with installation, troubleshooting, and maintenance. We also provide warranty coverage for our products and can assist with repairs and replacements. Our support staff is available 24/7 to help with any concerns or issues you may have with our Thermal Break Profile product.

Before sales

1. Introduce products in detail

2. Recommend suitable solutions

3. Provide with referene information

During manufacturing

1. Provide with layour and engineering conditions

2. Inform the processing status

3. Offer related documents

After sales

1. Provide installation, commissioning and training

2. Offer spare parts

3. Provide with necessary technical support

Packing and Shipping:

The Thermal Break Profile is packaged and shipped in cardboard boxes with bubble wrap for protection. The boxes are sealed with tape to ensure the product is not damaged during the shipping process. Inside the box, the product is individually wrapped in a clear plastic bag to provide additional protection.

![]()