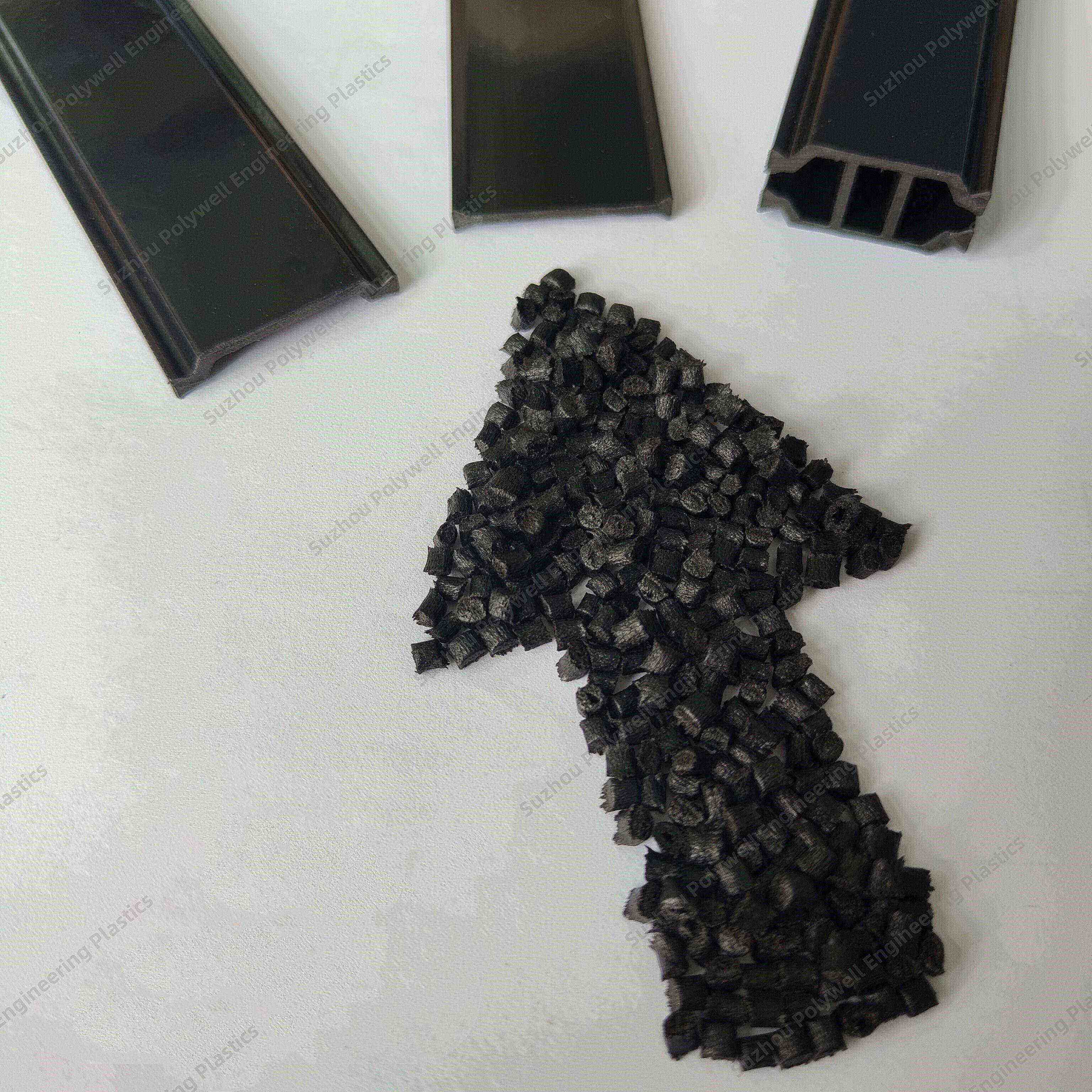

Poliamid issiqlik izolyatsiya tasmasi ishlab chiqarish uchun yuqori chiqish qora neylon PA66GF25 plastik kalıp granulalar

Texnik xususiyati: 25kg / bag

Trademark: Polywell

Origin: Zhangjiagang City, China

Surface Treatment: Smooth

Thickness: 2-4mm

Usage: Industrial / Household / Engineering Plastics / Construction material

Product Categories: FRP Granules

Molding Method: Extrusion

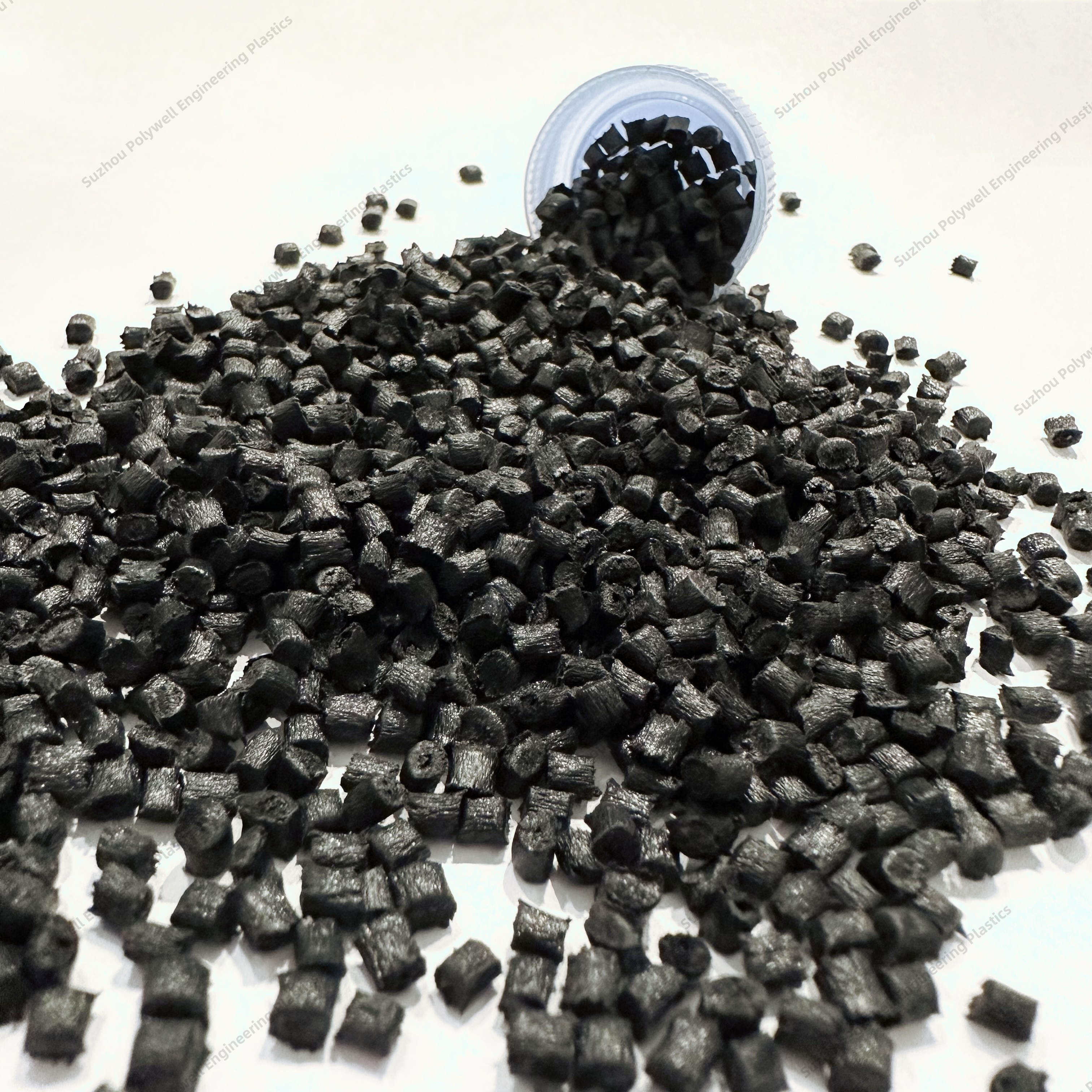

Material: Granules / Pellets / Particles

Fiber Type: GFRP

- Umumiy nuqtai

- Bog'liq mahsulotlar

- Namunaviy suv tarkibi og'irligi 0,2% dan kamroq.

- Norm laboratoriya shart:(23±2)ºC va (50±10)% nisbiy namlik.

- "A" bilan belgilangan texnik xususiyatlar faqat I-shaklidagi chiziq uchun qo'llaniladi, aks holda etkazib beruvchi va xaridor o'rtasida maslahat orqali tuzilgan texnik xususiyatlar shartnomada yoki sotib olish buyurtmasida yoziladi.

Mahsulot tavsifi:

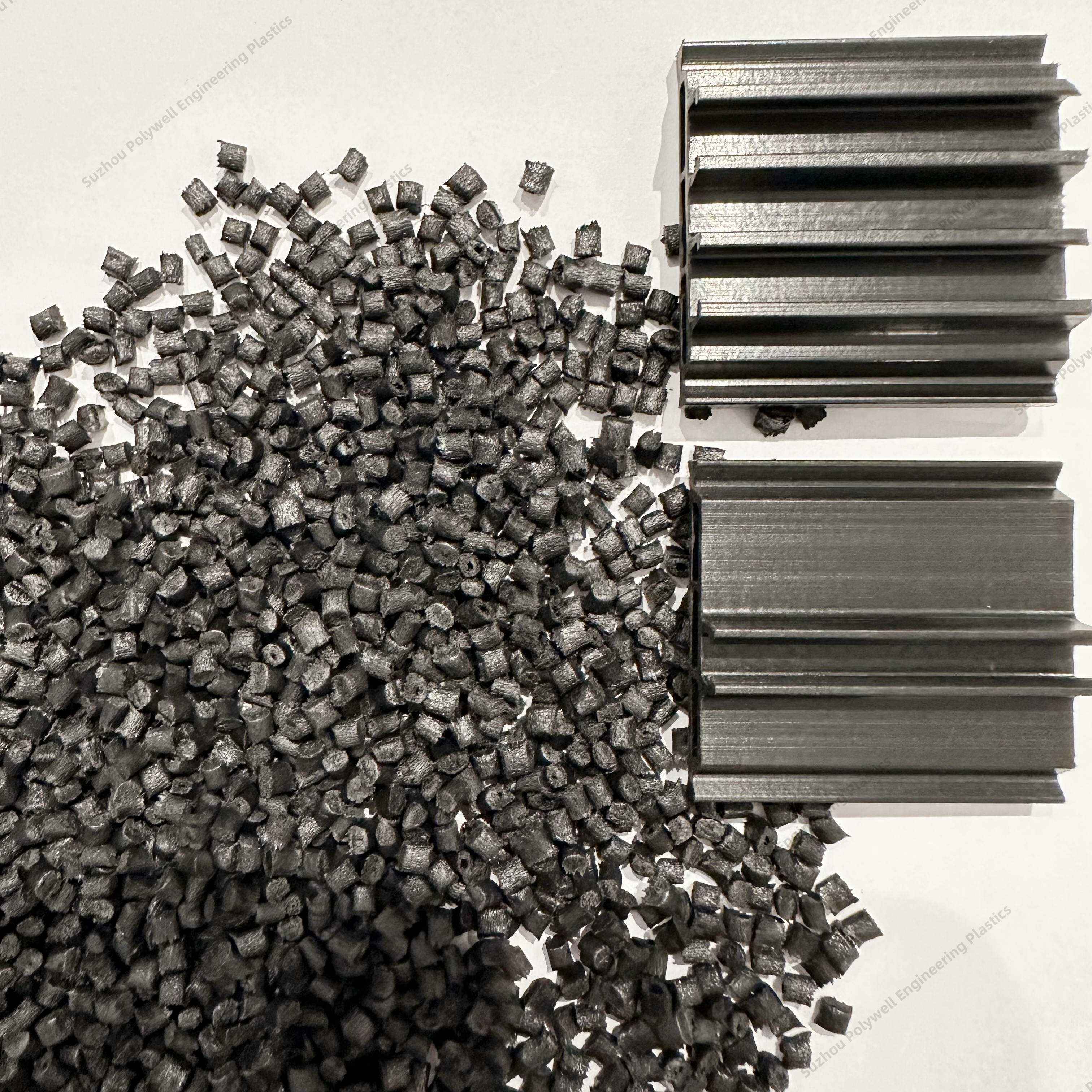

Issiqlik qarish qarshilik testrüzyon kalıplama sinf bilan shisha tolali mustahkam PA 6,6 dona. Bu yuqori qattiqlik va o'lchovli barqarorlikning termal tanaffus profillari uchun yaxshi xom ashyo.

-PA66GF25 granulalar shisha tolali bilan mustahkamlanadi. Ushbu xom ashyo yakuniy mahsulot ishlashi milliy standartga javob berishi mumkin.

-TPA66GF25 granulalari PA66 qatronlar asoslangan. Keyinchalik granulalar shisha tola, samarali otash geciktiriciler va har xil qo'shimchalar qo'shilgandan so'ng twin-vidalı ekstruziya mashinasi tomonidan hosil qilinadi.

Mahsulot tavsifi:

Shisha tolali bilan mustahkamlangan poliamid 6,6 granulalari, maxsus qo'shimchalar bilan aralashtiriladi va egizakli vintli ekstruziya mashinasi bilan ekstrudirovka qilinadi. Issiqlik izolyatsiyasi chizig'ini ekstruziya qilish uchun ko'proq mos keladi. Oddiy granulalar bilan solishtirganda, u shakllanish uchun ko'proq qulaydir. Tezlik, sirt qoplamasi va rentabellikda ma'lum afzalliklarga ega. Ushbu materialdan ishlab chiqarilgan neylon izolyatsiya ipining ishlash milliy standartlarga javob beradi. Bu nafaqat milliy standartdan ancha yuqori mijoz talablariga muvofiq tayyorlangan bo'lishi mumkin emas, balki otash geciktirici maqsadiga erishish uchun yuqori samarali otash geciktirici qo'shish mumkin.

Bizning PA66GF25 granulalari joriy etish:

Bizning PA66GF25 granulalari issiqlik izolyatsiya profillari uchun maxsus materialdir. Bu ekstruziya sinf o'zgartirilgan plastmassa. PA66 qatronidan farq qiladi.

Bizning PA66GF25 granulalari 25% shisha tola bilan mustahkamlanadi.

Xom ashyoni kiritish:

PA yuqori mexanik quvvat, yuqori yumshatish nuqtasi, yaxshi aşınma qarshilik, o'z-o'zini soqollash, yostiq, tovush o'chirish, mukammal neft va kimyoviy korroziya qarshilik va yaxshi elektr izolyatsiyaning afzalliklariga ega. Ushbu ustun ishlash tufayli, PA kompozit allaqachon tarkibiy materiallar sifatida ba'zi metallarni almashtirgan.

Mahsulot joriy etish:

-PA66GF25 granulalar shisha tolali bilan mustahkamlanadi. Ushbu xom ashyo yakuniy mahsulot ishlashi milliy standartga javob berishi mumkin.

-PA66GF25 granulalar PA66 qatronlari asoslangan. Keyinchalik granulalar shisha tola, samarali otash geciktiriciler va har xil qo'shimchalar qo'shilgandan so'ng twin-vidalı ekstruziya mashinasi tomonidan hosil qilinadi.

PA 66 GF25 nima?

PA66 GF25 25% shisha tolali mustahkamlangan PA 66 hisoblanadi. Yuqori kuch, qattiqlik, surilish kuchi va o'lchovli barqarorlik kabi ajoyib mexanik xususiyatlarni namoyish etadi.

PA 66 25% GF nima?

Kimyoviy jihatdan 25% shisha tolasi bilan mustahkamlangan, issiqlik stabilizatsiyalangan, yuqori kuch va yuqori ta'sirli kalıplar uchun mos bo'lgan qarshi kalıplama va ekstruziya kalıplama uchun PA 66. Avtomobil, muhandislik, elektr, Windows va eshiklar sanoatida ishlatiladi. 200 ° C gacha uzoq vaqt issiqlik ta'sir sodir bo'lgan muhitda foydalanish mumkin.

Poliamid 66 GF25 nima?

alyuminiy deraza, eshiklar va jabhada tizimlarida issiqlik izolyatsiya qilish uchun ilovalar turli uchun ishlatiladigan poliamid 66 GF25, quruq ta'sir chidamli (PA 66), poliamid (PA) yaxshi izolyatsiya xususiyatlari va ajoyib mexanik ishlashi taklif etadi

Shisha tolalar bilan mustahkamlangan, maxsus PA 66 GF25, quruq ta'sirga chidamli aralashmasi optimal natijalarga erishish uchun alyuminiy tizimlari uchun eng yaxshi yechimni taklif etadi

Yuqori aniqlikdagi ishlov berish

Cheksiz mavjudligi va qayta ishlanishi

PA66 neylon 66 bilan bir xilmi?

Poliamid 66 (PA66) yoki Neylon 66 eng mashhur muhandislik termoplastiklaridan biri bo'lib, asosan turli xil ilovalarda metall o'rnini bosuvchi sifatida ishlatiladi. Neylon 66 gekzametilendiamin va adipik kislotaning (har birida 6 ta uglerod atomini o'z ichiga olgan ikkita monomer) polikondensatsiyasi bilan sintezlanadi.

PA66 xususiyatlari

1. It has excellent mechanical properties, high strength, high toughness.

2. The material has excellent coloring ability, can achieve various requirements of color matching

3. The shrinkage rate of PA66 is between 1% and 2%. The addition of glass fiber additives can reduce the shrinkage rate to 0.2%~1%. The shrinkage ratio is large in the flow direction and in the direction perpendicular to the flow direction.

4. PA66 is resistant to many solvents, but is less resistant to acids and other chlorinating agents.

5. PA66 excellent flame retardant performance, by adding different flame retardants can achieve different levels of flame retardant effect.

Plastik materiallarda GF nima?

Glass-filled nylon is a synthetic polyamide thermoplastic and it's one of the most important materials used in engineering thanks to its strength and heat resistance. It's made by adding powdered glass to nylon resin or by extruding the plastic with glass fibers.

What is raw material for polyamide thermal break strips?

Polyamides are among the most important and proven technical thermoplastics, known for their heat resistance, stiffness and high mechanical stability.

Polyamides can be classified into different types, with PA 6, PA 6.6 and PA 12 most established on the market. Alongside ABS and PP compounds they are among the most widely used plastics, found across several sectors including the automotive, mechanical engineering, structural and installation engineering, photovoltaics and electrical engineering industries.

Glass fiber is a material consisting of numerous extremely fine fibers of glass.

Glass fibres are used as reinforcement of polymers in various fields such as aerospace, automobile, marine, sporting and leisure goods, and construction and civil engineering. One of the principal advantages of using glass fibres for reinforcement of polymers is their high performance per cost ratio.

Our company use PA 6.6 and glass fiber to produce PA66GF25 granules, which is the most suitable raw material for polyamide thermal break strips production.

Nima uchun termal uzilish profillarini ishlab chiqarish uchun poliamiddan foydalanish kerak? / Afzalliklari

Polyamides offer high levels of heat resistance, stiffness and high mechanical stability for a durable solution. Our special glass fiber reinforced PA 66 GF25, dry impact resistant mixture is ideal for the production of structural and reinforcement profiles.

Offering excellent heat resistance, polyamides can be used in the toughest of conditions, for example exposure to hot and humid environments. PA profiles can drastically reduce the Utj (U-Value of a thermal joint), which insulates the energy flow from the outside of the facade to the inside.

The uncomplicated processing of polyamides is another key benefit. With various properties that can be individually adapted according to the specific project and need, polyamides are the perfect choice for the manufacture of special extrusion profiles.

Bizning PA6.6-gf25 granulalarining afzalliklari:

Our company has devoted more than ten years to the research and development and production of nylon extruding profiles. According to customer reaction, using our PA66 granules for production can get high yield, easy start-up, and get less scrap in the early start-up stage. There will be no lack or incomplete of profiles in the production process, thus avoiding material waste, saving customer costs and improving production efficiency.

Afzalliklari:

1. We are a trading company with our own factory

We are professionally manufacturer of special material for polyamide thermal break profiles with over 10 years experience.

2. Good service & Top quality

Most perfect equipment, capable&experienced designers and skilled workers, advanced roduction management experience and strict quality management standard.

3. Quality control

Procedure is inspected and controlled before packing the goods. We ensure every piece of product shipped is good quality.

4. Customized Service

If your application requires something even more special, we will work with you to develop unique formulations to help you create products that will dazzle your customers!

Afzalligi:

1.High mechanical strength

2.High toughness

3.High softening point

4.Good wear resistance

5.Self-lubrication

6.Long-term work at higher temperatures

7.It has high CTI value , excellent electrical insulation , low smoke and low toxicity characteristics.

Rang haqida:

The color of our PA66GF25 granules is black, but we also can customize according to customers’ requirements.

Ilova:

Specially used in thermal break strips, thermal bridge, heat insulation bar, etc.

Ilova:

Specially used in thermal break strips, heat insulation bar, thermal insulation profiles, thermal broken bridge window,etc.

Ilova:

The PA66 granules with fiber glass are mainly used in thermal break strips, which are used in aluminum windows and doors.

Ilova:

The PA66 granules with fiber glass are mainly used in thermal break strips, which are used in aluminum windows and doors. Our granules have good fluidity thus guaranteeing your smooth production. The good raw material can reduce the rate of rejects, and can produce high quality strips.

Paket va etkazib berish:

Qadoqlash tafsilotlari |

25 kg / sumka |

Buyurtmani bajarish vaqti |

10-15 ish kuni |

Etkazib berish tafsilotlari |

20 futli konteyner boshiga 10-16 tonna 40 fut konteyner boshiga 20-25 tonna |

Ko'p so'raladigan savollar:

Q: namuna haqida

A: Namuna bepul, lekin ekspress haq yig'ishdir. Mijoz ham o'z hamkorlik kurerlik kompaniyasini tanlashi mumkin.

Savol: MOQ haqida

Javob: Poliamid granulalari uchun MOQ 1 tonna. Termal tanaffus chiziqlari uchun MOQ 5,000 metr.

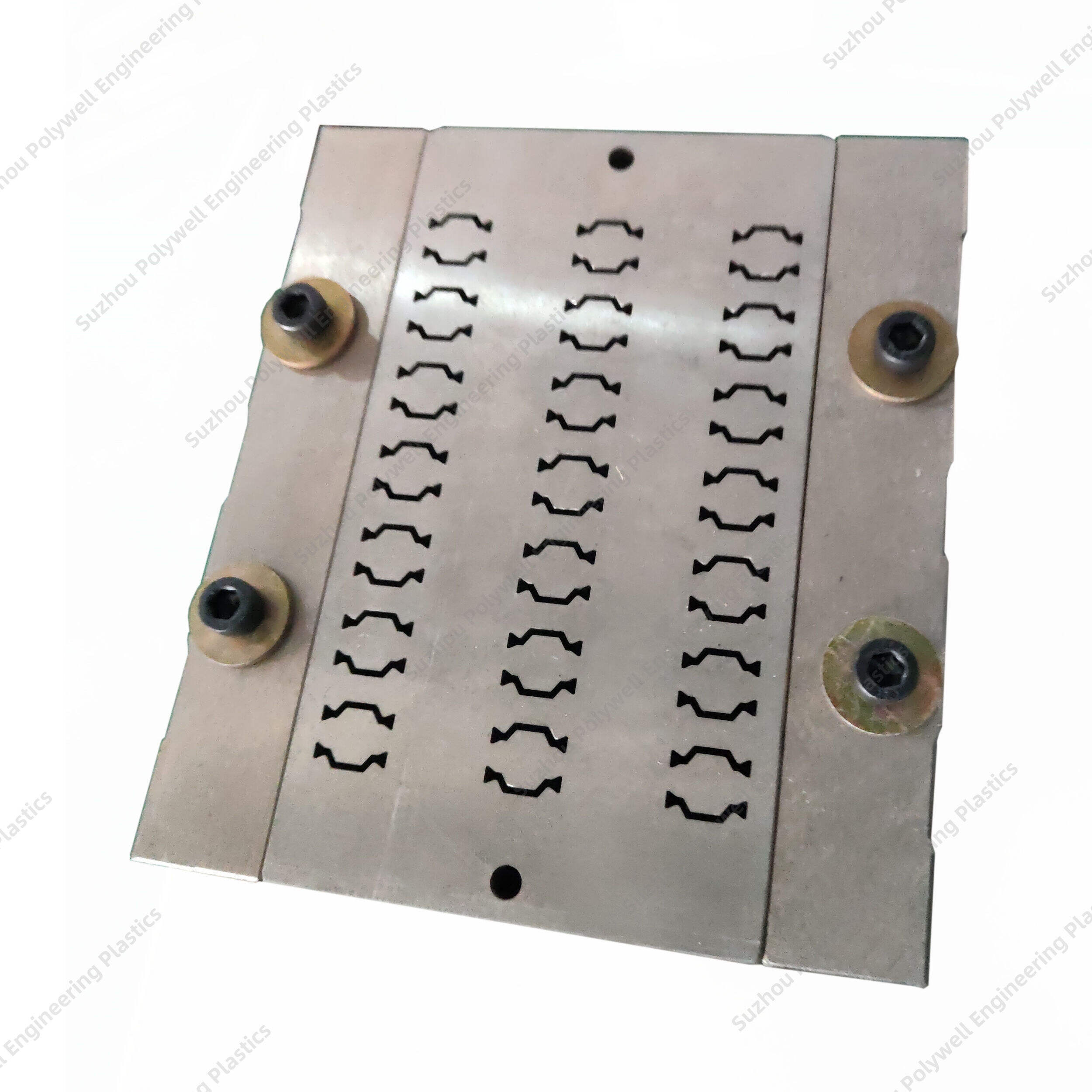

Savol: poliamid profillarning maxsus shaklini va uning davrini sozlash to'g'risida

Javob: Siz poliamid chiziqlarning maxsus shaklini sozlashingiz mumkin. Agar biz oldin bu shaklni kutib olmagan bo'lsak, biz siz uchun yangi qolip qilamiz va mijoz qolip uchun to'lash kerak.

Savol: Paket uslubi va belgilarini sozlash haqida

A: Siz paket uslubi va belgilarni moslashingiz mumkin.

Savol: Nima uchun sizning narxingiz boshqalarnikiga qaraganda yuqori / past?

Javob: Poliamid granulalari va termal tanaffus chiziqlariga ixtisoslashgan yillar davomida bizga tajribali va malakali texnik ishchilar va ishlab chiqarish ishchilarini berdi. Biz mahsulot barqarorligini va xom ashyoning yuqori sifatini va'da qilamiz. Bundan tashqari, biz yakuniy qurilma uchun xomashyo texnik qo'llab-quvvatlash mumkin.

Savol: kafolat haqida

A: 1 yil. Biz mahsulot ishonchimiz komil, va yetkazib oldin ularni to'plami, shuning uchun odatda siz yaxshi holatda buyurtma olasiz. Har qanday sifat masalasi, biz darhol u bilan shug'ullanadi.

Savol: To'lov yoki boshqa savol haqida

A: 50% T / T o'rnatishdan oldin ishlab chiqarish, 50% T / T muvozanat.

Mahsulot unumdorligi

Element |

Birlik |

GB / T 23615.1-2009 |

PW-Texnik tavsiflar |

Zichlik |

g / sm3 |

1.3±0.05 |

1.28-1.35 |

Chiziqli kengayish koeffitsienti |

K-1 |

(2.3-3.5)×10-5 |

(2.3-3.5)×10-5 |

Vicat yumshatuvchi harorat |

ºC |

≥230 |

≥233 |

Erish nuqtasi |

ºC |

≥240 |

≥240 |

Valentlik yoriqlari uchun sinov |

- |

Yoriqlar yo'q |

Yoriqlar yo'q |

Qirg'oq qattiqligi |

- |

80±5 |

77-85 |

Ta'siri kuchi(notched) |

KJ/m2 |

≥35 |

≥38 |

Valentlik kuch (bo'ylamasina) |

MPa |

≥80a |

≥82a |

Elastiklik moduli |

MPa |

≥4500 |

≥4550 |

Uzilishda choʻkishi |

% |

≥2.5 |

≥2.6 |

Valentlik kuchi (ko'ndalang) |

MPa |

≥70a |

≥70a |

Oliy harorat valentlik kuchi (ko'ndalang) |

MPa |

≥45a |

≥47a |

Past harorat valentlik kuchi (ko'ndalang) |

MPa |

≥80a |

≥81a |

Suv qarshilik valentlik kuchi (ko'ndalang) |

MPa |

≥35a |

≥35a |

Qarish qarshilik valentlik kuchi (ko'ndalang) |

MPa |

≥50a |

≥50a |

EN

EN