Single Screw PA Strip Extruder Machine Customized Polyamide Thermal Break Strip Extrusion Equipment

Machine Extrude Chain Guide Nylon Runway Guide Rial Guide

- Overview

- Recommended Products

- Automatic feeding machine

- Hopper dryer

- Main PA strip extrusion machine

- Molds/Tools/Dies

- Cutting machine

- Fixture device

- Cutting machine

- Worktable

- Winding machine

After-sales Service : Engineers Available to Service Overseas

Warranty : 1 Year

Type : Profile Extruder

Plastic Processed : PA66-gf

Product Type : Profile Extrusion Molding Machine

Product Type : PA profile

Feeding Mode : One Feed

Assembly Structure : Separate Type Extruder

Screw : Single-Screw

Engagement System : Non-Intermeshing

Screw Channel Structure : Deep Screw

Exhaust : Don’t Exhaust

Automation : Automatic

Computerized : Computerized

Transport Package : Plastic Foam Film or Plywood Case

Specification : 60mm/70mm/80mm

Trademark : Polywell

Origin : Zhangjiagang City, China

Material : Polyamide, Glass fiber

Usage : Produce Polyamide Strips

Plastic Properties After Heated : Thermoplastic Plastics

Plastic Forming Method : Extrusion

Application : Thermal Break Aluminum Profiles Production

Power : 15-20 kw

Weight: 900-1000 kgs

Speed: Around 8-14 cm per min

Suitable Strip Shape: All Kinds of Shape

HS code: 847720

Production Capacity: 40-50 sets per month

Customized : Customized

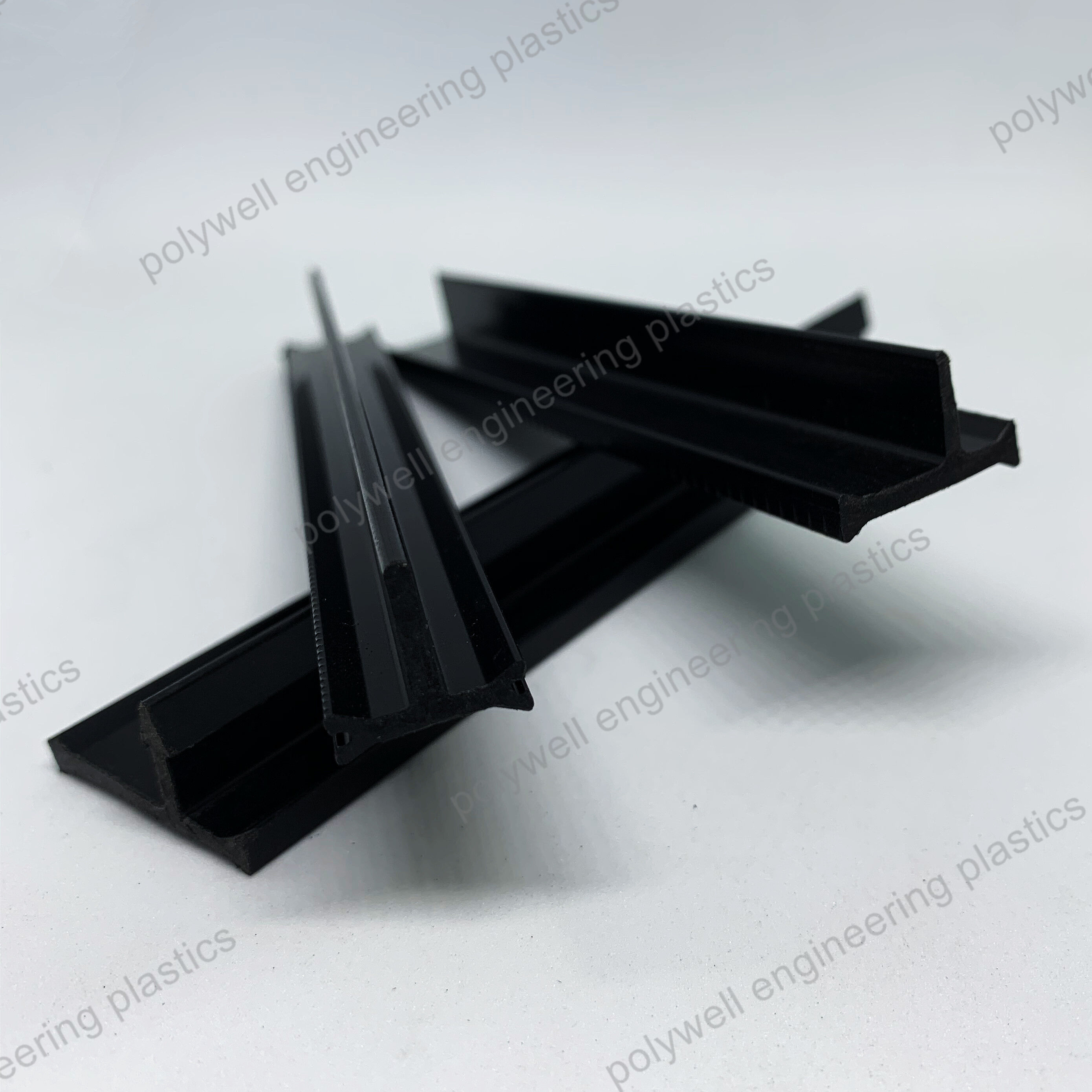

Polyamide Thermal Strip Processing Process

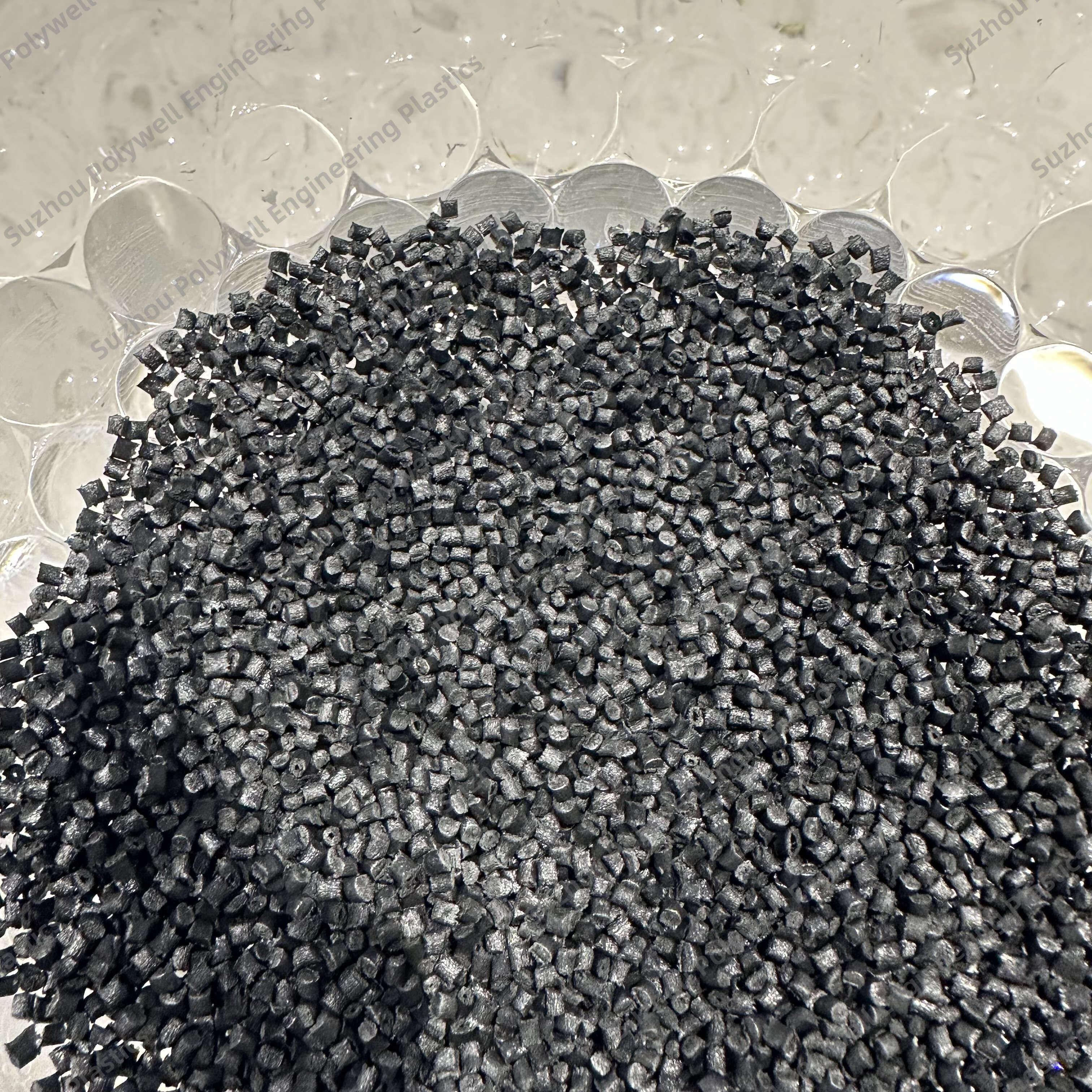

PA66GF25 granules are dried and get into the machine barrel through the hopper. The granules are in rotary contact with the machine screw, and move towards the mold with the rotation of the screw.

As the gap of machine screw and barrel is small, the granules are heated in the gap under the process of moving forward. They are plasticizied to nylon molten state through the high temperature of the electric heating ring body. The molten state of nylon is diverted and shaped after entering the mold, and finally extruded into heat insulation strips.

Plastic extruder for polyamide strips, also known as production machines for thermal break strips, are essential tools in the manufacturing industry. These machines, specifically the single screw extruder, play a crucial role in the process of plastic extrusion. By utilizing heat and pressure, they transform raw polyamide materials into high-quality strips that are widely used in various applications.

What does a plastic extruder do?

Plastics extrusion is a normally high volume manufacturing process where a polymer material, enriched with the desired additives, is melted and formed in a continuous process. The raw material (polymer) in the form of granulates, is gravity fed into the hopper and through the feed throat, drops on a rotating screw.

What is the basic principle of extrusion?

The basic mechanics of extrusion are simple—a screw turns in a barrel and pushes the plastic forward. A screw is really an inclined plane, or ramp, wound around a central core. The intent is to multiply the force so that a great resistance can be overcome.

What is extruder in polymer processing?

Plastic extrusion is a continuous high volume manufacturing process in which a thermoplastic material is homogeneously melted and then forced out of the shaping die by means of pressure. There are different types of an extruder.

The extruder we sell is single screw extruder for the production of PA thermal barrier profiles.

What is the function of plastic extruder?

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation.

The extrusion produces items of our plastic extruder is thermal break polyamide strips.

Features of our extruder:

1. The professional dryer distributes the material and hot air evenly, resulting in good drying uniformity.

2. The machine screw is a high-quality cemented carbide screw that ensures high plasticization of the PA66GF25 material.

3. The main engine is energy-efficient, and the speed is constant. The speeds of the main and auxiliary machines can be synchronized.

4. One imported temperature control meter controls a single temperature control system, ensuring temperature accuracy of ±1°C.

5. The machine screw barrel is heated with a stainless steel heater that can withstand 400 V.

6. The die head is made using German advanced technology, with a short runner and no dead angle. The surface of the heat insulating strip is bright, with accurate tolerances and high strength.

7. Worktable table with stainless steel strip setup position.The length of worktable is adjustable.

8. Winding machine: The torque motor control system adjusts the winding tension. Each roll specifies 300-600 meters.

FAQ

Q: What is your MOQ for the polyamide strip extrusion machine?

A: 1 set.

Q: As new player of polyamide strips extrusion, how we learn to use the machine?

A: Polywell will provide paper and videos files to help customer operate the machine. If customer needs, we can also provide on site training service.

Q: Can we customize and buy the raw materials and molds?

A: We can provide every product related to the polyamide thermal break profiles production. Including the raw material, the mold, the cutting machine, the worktable, the winder and so on.

Q: What is the warranty for your machine?

A: For extruder machine, it is one year. We are confident in our products, and pack them well before delivery, so usually you will receive your order in good condition. Any quality issue, we will deal with it immediately.

Q: What is your payment terms?

A: 50% T/T deposit before production, 50% T/T balance before loading.

Our Service

One to one consulting service.

Experienced senior engineer to discuss technical data, designed drawing.

Perfect arrangement of sea or air transport.

Overseas aftersales service.

Professional engineers team.

Welcomed to visit the factory at any time.

Choosing Polywell means choosing the certainty of a reliable partner, able to team up and offer daily support. We are where you need us, whenever you need us.

Production Speed |

Around 8-14cm/min |

Strip Shape |

All kinds of shape |

Raw Material |

PA6.6 granules reinforced by 25% glass fiber |

Cooling |

Water Cooling |

Usage |

Produce thermal break strip |

Type |

Plastic extrusion machine |

Winding Machine |

Available |

Cutting Machine |

Available |

Worktable |

Available |

PA66GF25 Polyamide Profiles Extrusion Machine Including:

EN

EN