-

Thermal Break Strip

-

Polyamide Nylon 66

-

Glass Filled Nylon 66

-

Broken Bridge Aluminum Window

-

Plastic Moulding Dies

-

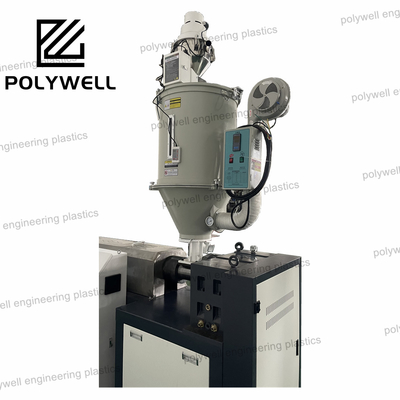

Nylon Extruder Machine

-

Single Screw Extruder

-

Pipe Production Line

-

Plastic Extrusion Machine

-

Aluminum Cutting Machine

-

Plastic Granulator Machine

-

Tensile Testing Machine

-

Laser Code Printer

-

Water Bottling Machine

-

Mr. Paolo CelaniThank you very much for very good news! We appreciate your honesty and collaboration. You have supplied good dies, all sizes within tolerance. We have ordered dies for a total amount of more than 200,000 USD and we are continuing to order. Thank you again to you and your very professional team.

Mr. Paolo CelaniThank you very much for very good news! We appreciate your honesty and collaboration. You have supplied good dies, all sizes within tolerance. We have ordered dies for a total amount of more than 200,000 USD and we are continuing to order. Thank you again to you and your very professional team. -

Mr. Martyn HainesThank you for your help with this order and if ever you need someone to tell customers how helpful you are just tell them to contact me.

Mr. Martyn HainesThank you for your help with this order and if ever you need someone to tell customers how helpful you are just tell them to contact me. -

Mr. Dietmar DürrI received your samples. I agree to Mr. Wölki, they looks pretty good. We will arrange the balance payment. Please pack the mold and send them asap.

Mr. Dietmar DürrI received your samples. I agree to Mr. Wölki, they looks pretty good. We will arrange the balance payment. Please pack the mold and send them asap.

PA Plastic Strip Single Screw Extruder Nylon 66 Thermal Break Profile Extrusion Production Line

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Thermal Break Strips Extruder Machine | Usage | Polyamide Strip Production |

|---|---|---|---|

| Raw Material | PA66 GF25 | Speed | Around 7-10cm/Min |

| Warranty | 12 Months | Condition | New |

| Screw Design | Single-screw | Voltage | 380V(customized) |

| Dimension(L*W*H) | 2.3m*1.5m*2.4m | Weight | 1-2 Ton |

| High Light | single screw extruder machine,single screw extrusion machine |

||

Product Description

Automatic extruding machine is for polyamide thermal break strips used in aliminun windows and doors. Many customer use thermal break aluminum profile to do big air conditioner to keep heat of cold air, then make use of energy saving. We provide quality extruder machine along with various molds and raw material-nylon granules, and also the subsequent technical assistance. This machine includes raw material auto loading device, heating system, thermal break strip extruder and strip drawing device.

This equipment is assembled with precision fittings such as bi-metal screw, screw barrel, imported frequency converter, imported temperature control meter and high-precision gear box. It is an excellent equipment for producing PA66 nylon extruding Profile.

Main Features

1. The main part of machinery adopts high-quality cemented carbide screw to ensure the high plasticization of PA66+GF25. The main engine is energy-saving and the speed is stable. The speed of the main and auxiliary machines can be synchronized.

2. The die head is made according to German advanced technology, with short runner and no dead angle. The surface of the heat insulating strip is bright, with accurate tolerance and high strength.

3. Using imported temperature control meter, one meter controls one temperature control system to control the temperature accuracy to ±1C°.

4. Operating floor: stainless steel strip placement slot. Adjustable length 6 meters

5. Winding machine: The torque motor control system is used to adjust the winding tension. 500 meters or 1000 meters per roll.

6. The barrel is heated by stainless steel heater, withstanding 400 V.

7. The professional dryer makes the material and the hot air convect evenly, and the drying uniformity is good. Its thermal insulation structure prevents heat dissipation and promotes energy saving.

Parameters of Single Screw Reactive Extruder

|

Model |

Capacity |

Screw diameter |

Power |

Voltage |

Loading of Dryer |

|---|---|---|---|---|---|

| PW-S60 | 18-25kg/h | 60mm | 8kw | 380V | 75kg |

| PW-S70 | 20-35kg/h | 70mm | 16kw | 380V | 100kg |

| PW-S80 | 20-60kg/h | 80mm | 25kw | 380V | 150kg |

Detailed Images

Extruder Machine for Thermal Break Strips

Automatic extruding machine is for polyamide thermal break strips used in aliminun windows and doors.

Our Company

Welcome to visit our company!

Please feel free to contact us if you have any questions.

Our Service

Before sales

1. Introduce products in detail

2. Recommend suitable solutions

3. Provide with reference information

During manufacturing

1. Provide with layout and engineering conditions

2. Inform the processing status

3. Offer related documents

After Sales

1. Provide installation, commissioning and training

2. Offer spare parts

3. Provide with necessary technical support

Packing & Delivery

|

Packaging

|

|

|

Weight

|

1 Ton

|

|

Packaging Details

|

The normal package is wooden box. If export to european countries,the wooden box will be fumigated.

If container is too tigher,we will use pe film for packing or pack it according to customers special request.

|

FAQ

About MOQ

For the polyamide granules, MOQ is 1 ton. For the thermal break strips, MOQ is 10,000 meters.

About Customizing Special shape of polyamide Profiles and its period

You can customize the special shape of polyamide strips. If we didn't meet this shape before, we will make new mold for you, and you should pay for the mold.

About Customizing Package Style and Marks

You can customize the package style and marks.

Why your price is higher/lower than others?

For years specializing in polyamide granules and thermal break strips has bestowed us experienced and skilled technical workers and production workers. We promise the stability of products and the high-quality of raw material. Furthermore, we can provide technical support from raw material to the final appliance. Believe in that you can get better products and service with lower price.

About warranty

We are confident in our products, and pack them well before delivery, so usually you will receive your order in good condition. . Any quality issue, we will deal with it immediately.

About Payment

50% T/T before production, 50% balance before shippment.

If you are interested in our company and products, please feel free to contact me.

Lydia

E-mail: lydia@szpolywell.cn

Tel: +86-15601568506 (WhatsApp)

Address: Yangshe Town, Zhangjiagang City, Jiangsu Province, China.