-

Thermal Break Strip

-

Polyamide Nylon 66

-

Glass Filled Nylon 66

-

Broken Bridge Aluminum Window

-

Plastic Moulding Dies

-

Nylon Extruder Machine

-

Single Screw Extruder

-

Pipe Production Line

-

Plastic Extrusion Machine

-

Aluminum Cutting Machine

-

Plastic Granulator Machine

-

Tensile Testing Machine

-

Laser Code Printer

-

Water Bottling Machine

-

Mr. Paolo CelaniThank you very much for very good news! We appreciate your honesty and collaboration. You have supplied good dies, all sizes within tolerance. We have ordered dies for a total amount of more than 200,000 USD and we are continuing to order. Thank you again to you and your very professional team.

Mr. Paolo CelaniThank you very much for very good news! We appreciate your honesty and collaboration. You have supplied good dies, all sizes within tolerance. We have ordered dies for a total amount of more than 200,000 USD and we are continuing to order. Thank you again to you and your very professional team. -

Mr. Martyn HainesThank you for your help with this order and if ever you need someone to tell customers how helpful you are just tell them to contact me.

Mr. Martyn HainesThank you for your help with this order and if ever you need someone to tell customers how helpful you are just tell them to contact me. -

Mr. Dietmar DürrI received your samples. I agree to Mr. Wölki, they looks pretty good. We will arrange the balance payment. Please pack the mold and send them asap.

Mr. Dietmar DürrI received your samples. I agree to Mr. Wölki, they looks pretty good. We will arrange the balance payment. Please pack the mold and send them asap.

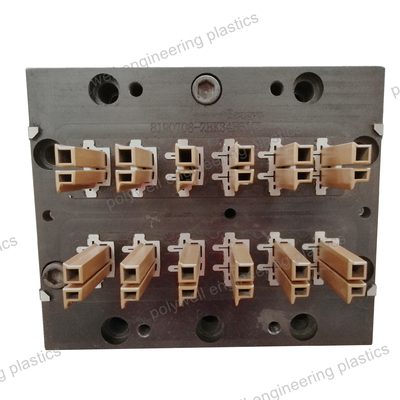

Plastic Moulds And Dies For PA Profile Extrusion Line Die Casting Mold Used On Polyamide Extrusion Machine

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Plastic Material | PA66 With 25% Glass Fiber | Cavity | Multi Cavity |

|---|---|---|---|

| Design Software | AutoCAD | Application | Used Household Appliances |

| Runner | Cold Hot Runner | Surface Treatment | Polishing |

| Shape | Customized | Shaping Mode | Extrusion Mould |

| Specification | Stainless Steel | Size | Various Types |

| Port | Shanghai | ||

| High Light | plastic extrusion dies,plastic moulds and dies |

||

Plastic Moulds And Dies For PA Profile Extrusion Line, Die Casting Mold Used On Polymer Extrusion Machine

What is plastic moulds for PA profile extrusion line?

PA profile means polyamide thermal break strips. Which is one of the most common materials used for years to create thermal breaks in curtainwalls, commercial windows, doors, and more. It is a reinforced polyamide strip, which occurs as a non-metallic, composite, structural material, and is installed between the interior and exterior profiles of the windows that forms an insulating barrier between the two.

The shape, size and output of polyamide strips are determined by plastic moulds. Therefore, plastic mould is a very important and indispensable part of the polyamide strips extrusion line.

1. Size: Customized

2. Standard: HASCO

3. Certification: SGS

|

Product Name |

Die for plastic moulding |

|

Material |

Mold steel |

|

Color |

nickel white |

|

Standard |

HASCO |

|

Cavity |

20-200 |

|

Design Software |

AutoCAD |

|

Condition |

New |

|

Plastic Processed |

PA66GF25 granules |

|

Brand Name |

Polywell |

|

Weight |

60-150kg |

- We can provide an overall solution for the production of polyamide strips, including the raw material-PA66GF25 granules, the PA extrusion machine, the plastic mold, the polyamide strips, the production technologh and thermal bridge aluminum window.

- we can provide professional sales and after sales service with good business atttidue

- For mold, our engineers follow the molds' production every week to make sure that all of them are in schedule, so that we can delivery the mold in time.

- After mold production finished, we will have a trial run to check whether the shape and strip sizes are qualified.

- We will send the strip sample and dimension report to our clients for approval.

- If everything is ok, we will do final inspection on the molds and accessories before shipment.

Thermal Break Strips

PA66GF25 Thermal Barrier Strip-used in heat insulation aluminum windows and doors.

Thermal Break Strips Extruding Machine

Automatic Polyamide66 Thermal Break Strips Extruding Machine.

Polyamide Granules

The product is based on PA66 resin as basic, add glass fiber, efficient flame retardants and various additives, formed by twin-screw extrusion blending.

Before sales

1. Introduce products in detail

2. Recommend suitable solutions

3. Provide with reference information

During manufacturing

1. Provide with layout and engineering conditions

2. Inform the processing status

3. Offer related documents

After Sales

1. Provide installation, commissioning and training

2. Offer spare parts

3. Provide with necessary technical support

About MOQ

For the polyamide granules, MOQ is 1 ton. For the thermal break strips, MOQ is 5,000 meters.

For mold and extrusion machien, MOQ is 1 set.

About Customizing Special shape of polyamide Profiles and its period

You can customize the special shape of polyamide strips. If we didn't meet this shape before, we will make new mold for you, but you need to pay for the mold.

About Customizing Package Style and Marks

You can customize the package style and marks.

Why your price is higher/lower than others?

For years specializing in polyamide granules and thermal break strips has bestowed us experienced and skilled technical workers and production workers. We promise the stability of products and the high-quality of raw material. Furthermore, we can provide technical support from raw material to the final appliance. Believe in that you can get better products and service with lower price.

About warranty

We are confident in our products, and pack them well before delivery, so usually you will receive your order in good condition. . Any quality issue, we will deal with it immediately.

About Payment or other question

50% T/T before production, balance before loading.

If you have any question, pls feel free to contact us as below:

Email: camille@szpolywell.cn

Phone:86-13584481777