Polyamide Sound Insulation Barrier Nylon Extrusion Strips Insert into Aluminum System Window

Nylon Chain Guide Profile Rail Guide Runway Guide PA66 Profile

- Overview

- Recommended Products

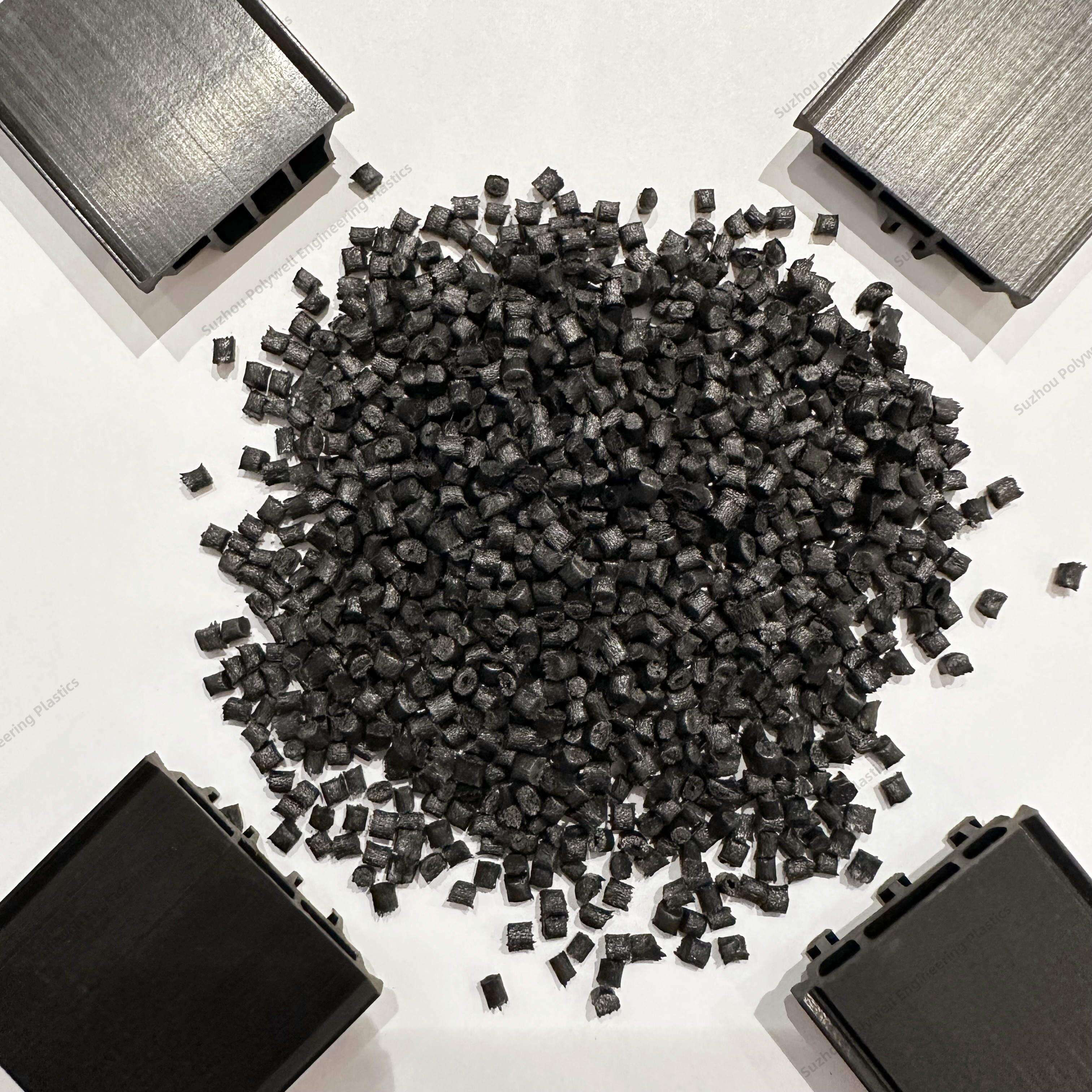

What is Polyamide Thermal Break Strip (PA66 GF25%)

There are many different materials to produce thermal break strips, such as PA66 GF25%, ASA, ABS, PVC. Among them, polyamide material is the most popular material for thermal break. Thermal insulating profiles made of polyamide PA 66 GF25% (25% glass fiber reinforced polyamide) have significant advantages.

The coefficient of linear thermal expansion (linear elongation coefficient) of the polyamide profiles is equivalent to the aluminum profile. Therefore, the polyamide profile is not subjected to internal stresses after it is pressed to aluminum profile. This is one of the most important advantages of using the polyamide material as a thermal barrier.

Secondly, the deflection temperature of the polyamide profiles under load is high. Even at 200° C for about 15 minutes, no deformation occurs. Therefore, it can easily be heated in the ovens at the powder coating process.

Thirdly, polyamide profiles do not emit toxic gases in case of fire. They are environmentally friendly.

In addition, dimensional stability and resistance to chemicals of polyamide thermal barriers are high.

Can polyamide strips thermally break aluminum extrusion assemblies?

Yes.

Structural insulating polyamide strips have been utilized for thermally breaking aluminum extrusion assemblies for over 30 years and have been in use in north america for over a decade. Polyamide strips are available with many configurations to meet different performance specifications. Creating a thermal break utilizing a polyamide strip system entails a 3 step process.

1. Profile knurling

2. Strip insertion

3. Crimping

What does a thermal break do?

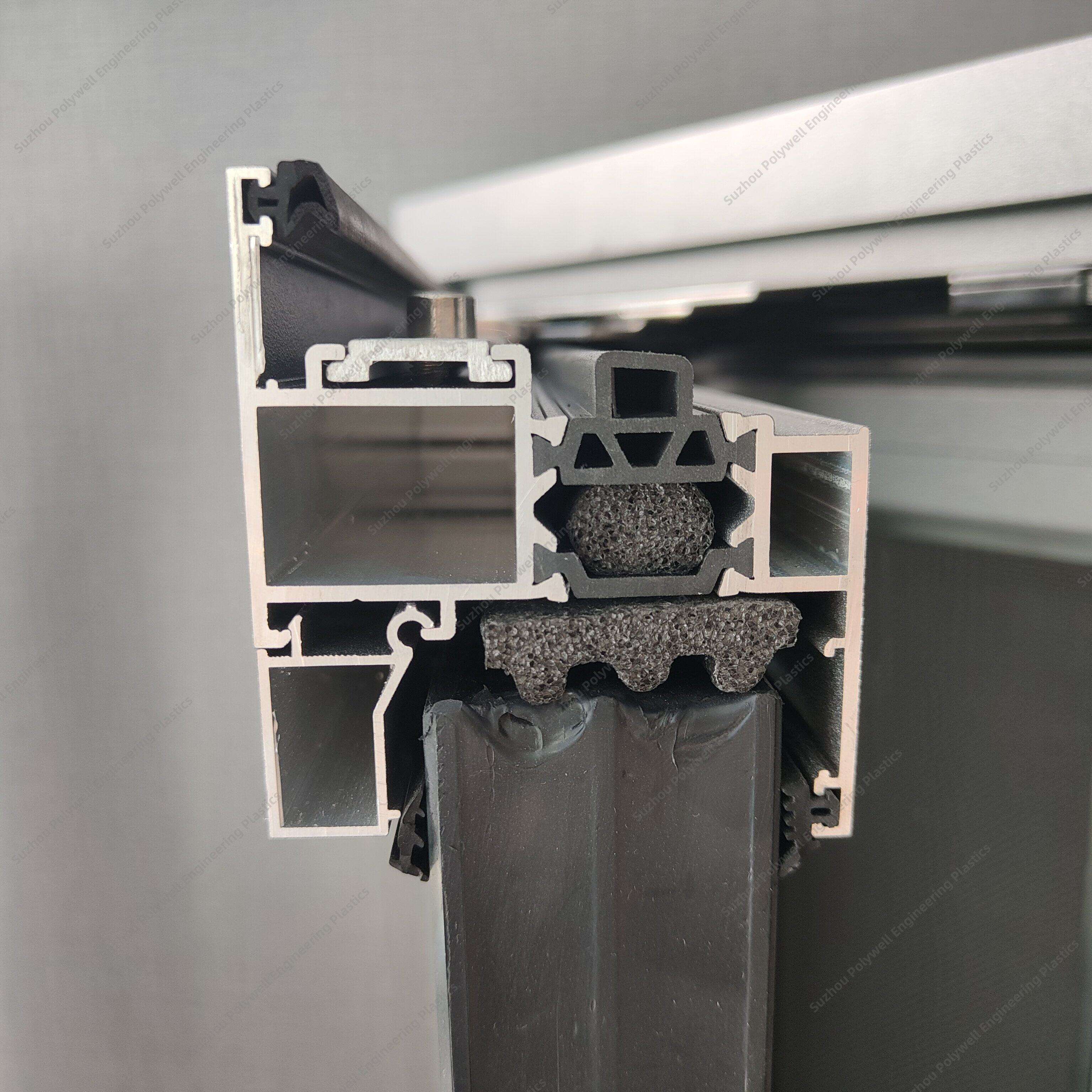

A thermal break is defined as a material with low thermal conductivity placed in an extrusion with the purpose of reducing the flow of thermal energy (heat). In aluminum windows, three types of thermal breaks are used. A standard pocket thermal break has been used in the window industry for decades.

The Function of Thermal Break Windows

1. Broken bridge aluminum thermal break strips reduce heat conduction: the heat broken bridge aluminum alloy profiles are adopted, and the hollow glass structure is adopted. The broken bridge aluminum doors and windows reduce the heat conduction through the doors and windows. In this way, it will not feel hot under the high temperature of the scorching sun in summer. It's cold and windy in winter, and we don't feel cold. This ensures that the indoor temperature is maintained.

2. Prevent condensation: The temperature of the inner surface of the broken bridge aluminum door and window profile with thermal break strips is close to the indoor temperature, reducing the possibility of indoor moisture condensing on the surface of the profile due to supersaturation. This is crucial for the insulation of the window.

3. The broken bridge aluminum thermal break strip plays the role of heat preservation and energy saving. Broken bridge aluminum door and window frames with thermal insulation strips can reduce the heat loss through the window frames by one-third. In summer, if there is an air conditioner, window frames with thermal insulation strips can reduce energy loss more.

4. To protect the environment: through the application of the thermal insulation system of broken bridge aluminum doors and windows, energy consumption can be reduced, and the environmental radiation caused by air conditioning and heating can be reduced at the same time.

5. Broken bridge aluminum thermal break strips are good for health: the heat exchange between the human body and the environment depends on the indoor air temperature, air flow speed and outdoor air temperature. By adjusting the indoor temperature of broken bridge aluminum doors and windows, the use is lower than 12~13 ℃, and the most comfortable environment has been achieved.

6. Broken bridge aluminum thermal break strips reduce noise: the use of hollow glass structures with different thicknesses and heat-insulated bridge-broken aluminum profile cavity structures can effectively reduce the resonance effect of sound waves, organize sound transmission, and reduce noise by more than 30dB.

What is a Thermal Barrier?

Thermal barriers are made from resins that create a “thermal break” between the inner and outer surfaces of aluminum fenestration.

Thermal barriers reduce heat loss or heat gain through the aluminum.

Thermal barriers improve the U-value characteristics of finished systems.

Thermal barriers are about energy conservation, U-values and government codes.

70 percent of aluminum fenestration systems produced in North America contain a thermal break.

Primarily used in colder climates to reduce heat loss.

Increasing use of thermal barriers to reduce heat gain and also reduce heat loss.

Developers, architects and designers are demanding better performance in terms of power usage.

Stricter government regulations to reduce power usage in buildings to combat environmental concerns.

Aluminum, if it is to retain its market superiority in terms of its structural integrity, will have to achieve better performance in terms of U-values.

The use of thermal barriers will assist manufacturers to achieve improved LEED performance.

Better Performance Than Other Types

The function of PA thermal break strip and the comparison of PVC thermal break strip.

The main raw material of PA thermal break strip is PA66 plus 25% glass fiber, and the main raw material of PVC thermal break strip is PVC resin powder plus 25% calcium carbonate. Compared with PVC thermal break strip, PA66 thermal break strip has the following advantages:

(1) High tensile strength Nylon thermal break strip:≥126N/mm

PVC thermal break strip: about 70N/mm.

(2) High thermal deformation temperature PA thermal break strip: 240℃ PVC thermal break strip: 90℃.

(3) It is more durable. PVC insulation strips are easy to age.

(4) Good self-extinguishing function.

Why Should Choose PA66 Thermal Strips in Windows Instead of Other Materials?

Experiments have proved that under the action of thermal expansion and contraction, the PA66 nylon insulation strip has the same strength, rigidity and thermal deformation temperature as aluminum alloy, which avoids the danger of the thermal insulation strip and the aluminum alloy profile falling off due to thermal expansion and contraction. , is a very critical material to ensure the safety of doors and windows.

PA66 nylon insulation strip is made of polyamide 66 as the base material, adding 25% glass fiber and 10% additives.

The advantages of nylon heat insulation strips: anti-alkali, anti-weak acid, anti-salt spray, anti-ultraviolet performance is good, the melt temperature is 252 degrees Celsius, which can effectively ensure the service life of doors and windows.

Application of polyamide strip:

1. Used for thermal break aluminum window, door, curtain and walls.

2. Many customer use thermal break aluminum profile to do big air conditioner to keep heat of cold air, then make use of energy saving.

Characteristic of PA strips

According to different storage time and ambient climate, the dimension of PA strips will increase slightly because of the natural moisture absorption. And the mechanical properties will change slightly too.

So, PA strips should be transported and stored under dry conditions away from the influence of weather. (rain, direct sunlight etc.)

What is the Suitable Width for Thermal Break Strips in Windows?

Generally speaking, the wider the heat insulation strip, the better. Under the premise of no damage to the product and the stability and quality of the heat insulation strip, the wider the aluminum insulation strip, the better, because the wider the heat insulation strip, the less heat transfer. The slower the window is, the better the insulation performance of the window is, and the more energy-saving it is, but the insulation strip must use PA66GF25 nylon strip.

On the contrary, if there is no quality assurance of aluminum material, poor or damaged heat insulation strips, and the toughness of the product is not up to standard, it is recommended not to choose windows with too wide heat insulation strips, because the overall airtight system is a whole system , everything has a standard, and the one that fits the standard is the best. If the heat insulation strip is narrow, the heat insulation will be worse. If the heat insulation strip is wide, it will affect the doors and windows. Other materials will be less. The load-bearing strength of the doors and windows will be reduced.

Take 70 broken bridge aluminum doors and windows as an example: the standard width of the window insulation strip is between 2 cm and 2.5 cm, and it should not be too wide or too narrow; if it is 80 series or 90 series broken bridge aluminum doors and windows, wider insulation strips can be used. For heat strips, it is recommended that if the heat insulation strip exceeds 4 cm, it is better to choose imported brand heat insulation strips or brand heat insulation strips produced by domestic large-scale heat insulation strip factories.

When the width of the heat insulation strip reaches more than 40mm, the stability of the system will become worse, and with the increase of the cavity between the heat insulation strips, the loss of heat due to the convection effect will become more and more obvious, so the wider the heat insulation strip, The material composition and design of the heat insulation strip are obviously different from the conventional heat insulation strips. The wider heat insulation strips should use mesh heat insulation strips or spacer cavities in the middle, which greatly improves the stability and heat insulation and sound insulation performance of the heat insulation strips.

PA strips storage and handling:

Because PA66 is a hydrophilic substance, it will absorb the surrounding water. The rate and amount of water absorption depend on the ambient temperature, ambient humidity and storage period.

The relative humidity is higher in summer than in other short-term storage seasons. High moisture content (more than 2%) will affect the quality of wear-resistant strips.

When the insulation single bundle is removed from the shelf, it may be deformed. If it is not straightened in time, it will cause permanent deformation.

Therefore, it is recommended to keep it horizontal in a ventilated and dry environment, pay attention to waterproof, stay away from heat source, avoid stress and minimize bending.

If you have any specific questions, please contact us and we are happy to provide you with relevant services.

Package

For all specifications / shapes, they could be packaged in linear, the length will be 6 meters, or customized.

For the Shape "I" "C", and some simple shapes, they can be packed in rolls. The length usually is around 300-600 meters per roll.

Our service about test

1.Size precision inspection insulation, according to the national standard GB/T23615.1-2017, the size precision of detection for customers of heat insulation strip.

2.Detection and analysis of insulation of internal structure, according to the national standard GB/T23615.1-2017.analyze the internal structure of insulation detection for customers.

3.Insulation density test, according to the national standard GB/T23615.1-2017, the application of electronic weighing instrument for detecting insulation density.

4.According to the national standard GB/T23615.1-2017, the insulation room temperature transverse tensile characteristic value, non-notched impact strength, high temperature and transverse tensile characteristic value of the test.

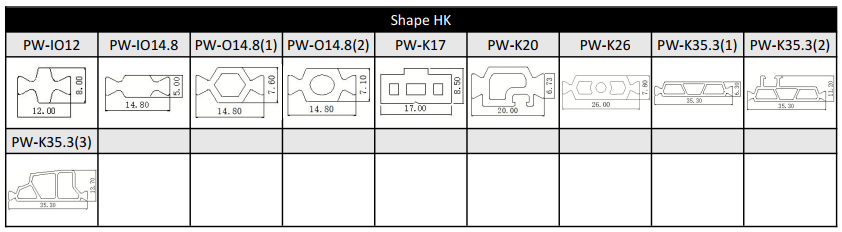

Different shapes:

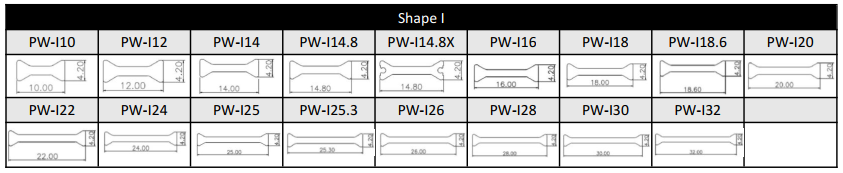

I-type thermal break strip is a common insulation material for doors and windows, with a shape similar to the uppercase English letter "I". It is the first generation and easiest shape of polyamide strips.

Compared to other types of thermal break strips, the advantage of I-type strips is that their longer length can better adapt to the width of doors and windows, improving the thermal break effect.

In addition, Type I insulation strips can also adapt to different door and window sizes and specifications through their own shape and structure, with high flexibility and adaptability.

For the I-type strips, we can provide the following size or customize according to customer’s drawing.

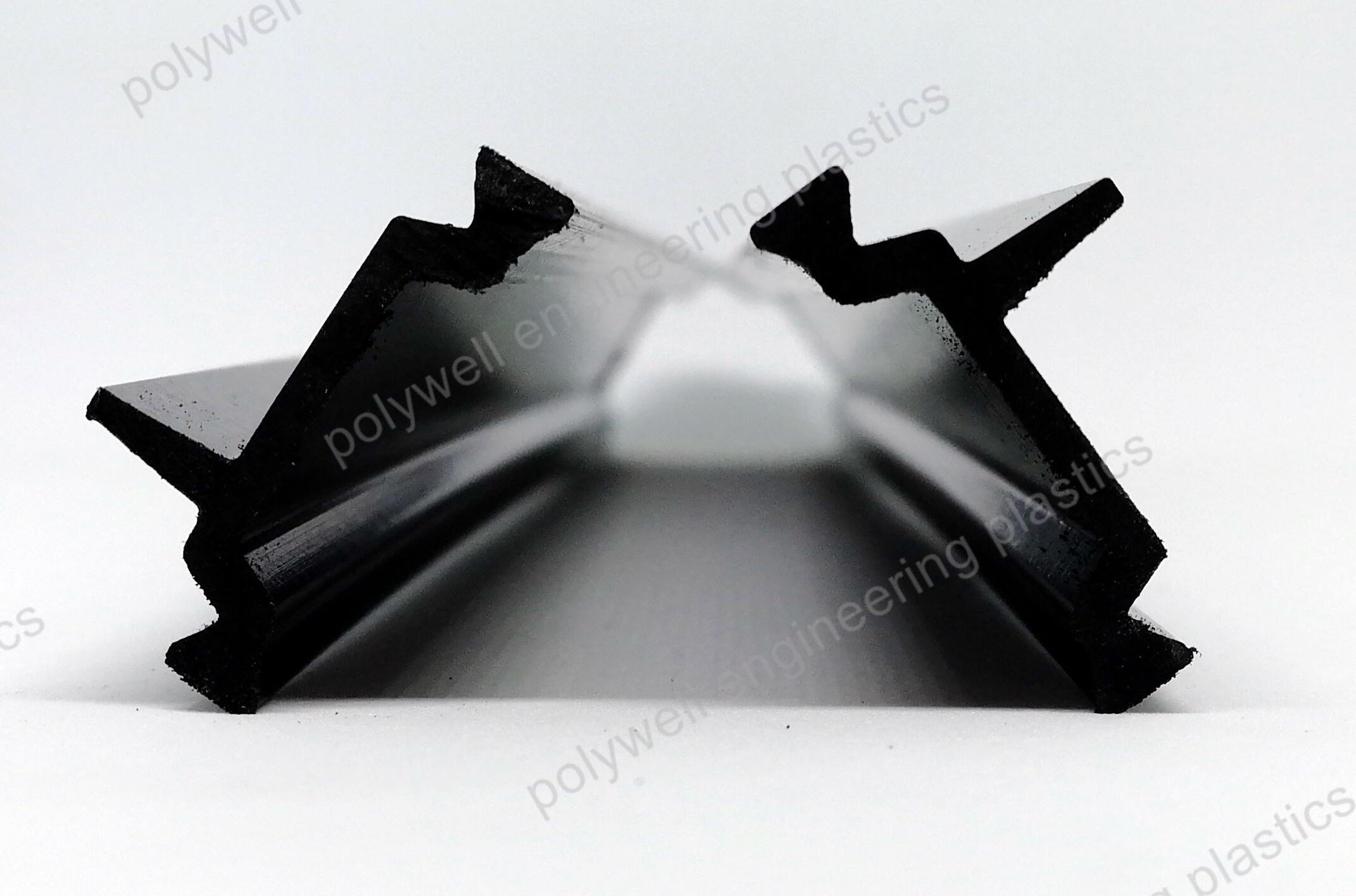

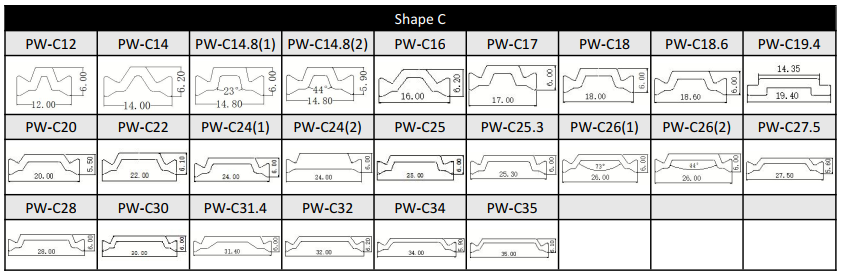

The C-type design provides a longer heat conduction path, resulting in better heat insulation performance than I-type strip, while also having better longitudinal load-bearing capacity. Besides, the C-type PA strip is also a necessary condition for the stepped drainage of thermal broken bridge aluminum.

For the C-type strip, we can provide the following size or customize according to customer's drawing.

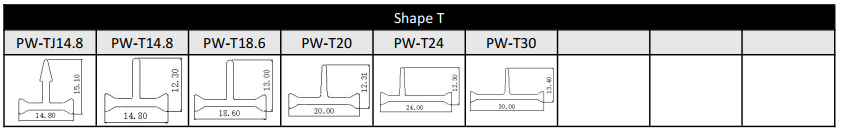

The design of T-type thermal break strips usually includes a horizontal section and a vertical section, forming a "T" - shaped structure.

This design adds a small section under the thermal break strip, allowing the sealing strip to overlap with the thermal break strips, thereby improving the overall insulation performance.

For the T-type strip, we can provide the following size or customize according to customer's drawing.

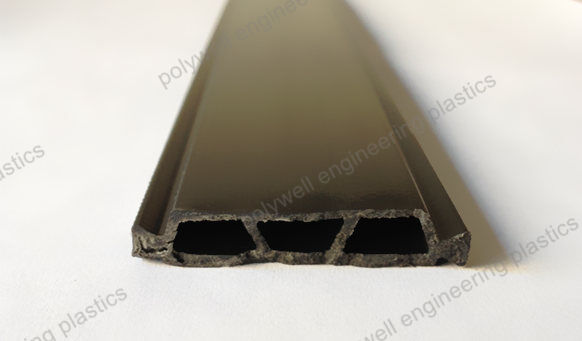

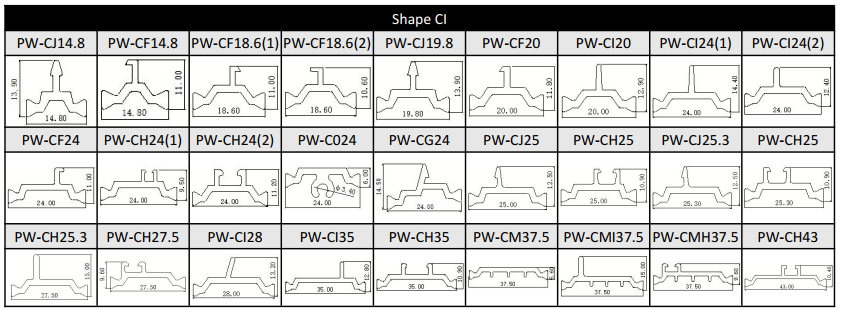

Hollow thermal break strip, also known as multi-cavity insulation strip, can reduce heat transfer by changing the air flow path, thereby achieving insulation effect and further improving insulation performance.

Hollow thermal break strip are currently the mainstream products in the market and can support large width sizes. Many thermal break strips with a diameter of 35mm or more on the market are made into multi-cavity shapes, and their longitudinal load-bearing capacity is very high.

For the hollow type strip, we can provide the following size or customize according to customer's drawing.

Product Performance

Item |

Unit |

GB/T 23615.1-2009 |

PW-Technical specification |

Density |

g/cm3 |

1.3±0.05 |

1.28-1.35 |

Linear expansion coefficient |

K-1 |

(2.3-3.5)×10-5 |

(2.3-3.5)×10-5 |

Vicat softening temperature |

ºC |

≥230 |

≥233 |

Melting point |

ºC |

≥240 |

≥240 |

Testing for tensile cracks |

- |

No cracks |

No cracks |

Shore hardness |

- |

80±5 |

77-85 |

Impact strength(Unnotched) |

KJ/m2 |

≥35 |

≥38 |

Tensile strength(longitudinal) |

MPa |

≥80a |

≥82a |

Elasticity modulus |

MPa |

≥4500 |

≥4550 |

Elongation at break |

% |

≥2.5 |

≥2.6 |

Tensile strength(transverse) |

MPa |

≥70a |

≥70a |

High temperature tensile strength(transverse) |

MPa |

≥45a |

≥47a |

Low temperature tensile strength(transverse) |

MPa |

≥80a |

≥81a |

Water resistance tensile strength(transverse) |

MPa |

≥35a |

≥35a |

Aging resistance tensile strength(transverse) |

MPa |

≥50a |

≥50a |

1. Sample water content less than 0.2% by weight.

2. Norm laboratory condition:(23±2)ºC and (50±10)% relative humidity.

3. The specifications marked with "a" only applies to I-shape strip otherwise, the specifications concluded between supplier and buyer through consultation, shall be written in contract or purchase order.

EN

EN