Plastic Machinery Extrusion Production Line Maintenance Free Polyamide Thermal Break Strip Single Screw Extruder

- Overview

- Related Products

- Automatic feeding machine

- Hopper dryer

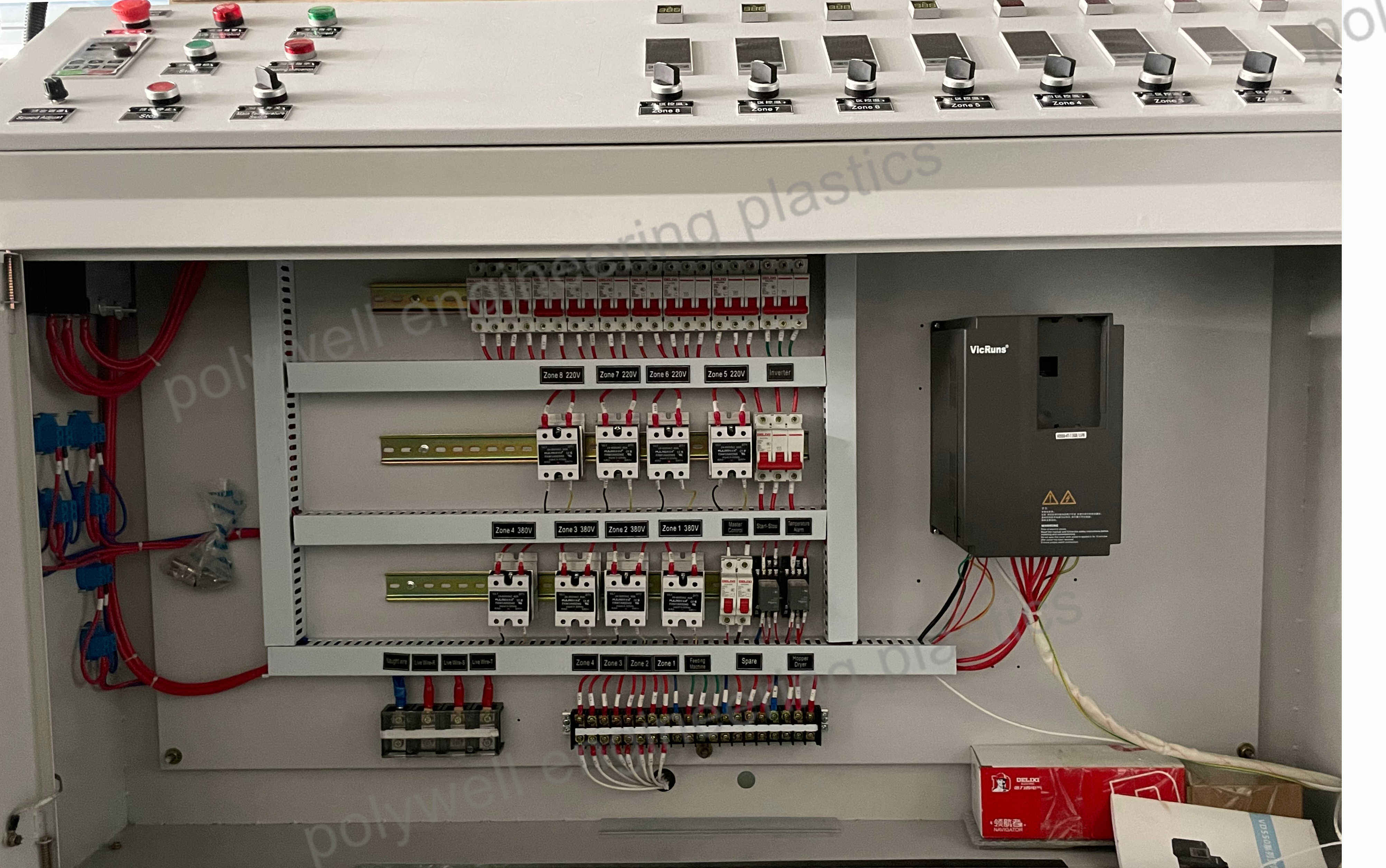

- Main PA strip extrusion machine

- Molds/Tools/Dies

- Cutting machine

- Fixture device

- Cutting machine

- Worktable

- Winding machine

After-sales Service : Engineers Available to Service Overseas

Warranty : 1 Year

Type : Profile Extruder

Plastic Processed : PA66-gf

Product Type : Profile Extrusion Molding Machine

Product Type : PA profile

Feeding Mode : One Feed

Assembly Structure : Separate Type Extruder

Screw : Single-Screw

Engagement System : Non-Intermeshing

Screw Channel Structure : Deep Screw

Exhaust : Don’t Exhaust

Automation : Automatic

Computerized : Computerized

Transport Package : Plastic Foam Film or Plywood Case

Specification : 60mm/70mm/80mm

Trademark : Polywell

Origin : Zhangjiagang City, China

Material : Polyamide, Glass fiber

Usage : Produce Polyamide Strips

Plastic Properties After Heated : Thermoplastic Plastics

Plastic Forming Method : Extrusion

Application : Thermal Break Aluminum Profiles Production

Power : 15-20 kw

Weight: 900-1000 kgs

Speed: Around 8-14 cm per min

Suitable Strip Shape: All Kinds of Shape

HS code: 847720

Production Capacity: 40-50 sets per month

Customized : Customized

Polyamide Thermal Strip Processing Process

PA66GF25 granules are dried and get into the machine barrel through the hopper. The granules are in rotary contact with the machine screw, and move towards the mold with the rotation of the screw.

As the gap of machine screw and barrel is small, the granules are heated in the gap under the process of moving forward. They are plasticizied to nylon molten state through the high temperature of the electric heating ring body. The molten state of nylon is diverted and shaped after entering the mold, and finally extruded into heat insulation strips.

Plastic extruder for polyamide strips, also known as production machines for thermal break strips, are essential tools in the manufacturing industry. These machines, specifically the single screw extruder, play a crucial role in the process of plastic extrusion. By utilizing heat and pressure, they transform raw polyamide materials into high-quality strips that are widely used in various applications.

The key point to highlight here is the versatility and efficiency of plastic extrusion machines. These machines are designed to handle the extrusion process with precision and consistency, ensuring the production of uniform and durable polyamide strips. With their advanced technology and reliable performance, they enable manufacturers to meet the increasing demand for thermal break strips in construction, automotive, and other industries.

In conclusion, plastic extruder for polyamide strips, or thermal break strip production machines, are indispensable assets for any manufacturing facility. Their ability to produce high-quality strips efficiently makes them a valuable investment for businesses aiming to enhance their production capabilities.

What does a plastic extruder do?

Plastics extrusion is a normally high volume manufacturing process where a polymer material, enriched with the desired additives, is melted and formed in a continuous process. The raw material (polymer) in the form of granulates, is gravity fed into the hopper and through the feed throat, drops on a rotating screw.

What is function of PA plastic profile extrusion machine?

To produce polyamide thermal break profiles. Polyamide thermal break strips also know as heat insulation profiles.

What is the raw material of PA plastic profile extrusion machine?

Polyamide6.6 granules reinforced by 25% glass fiber.

What is polyamide thermal break profiles?

Polyamide is used for over 30-50 years to create strips that serve as thermal breaks. This is because of the low thermal conductivity that polyamide boasts of. Such a property helps polyamide reduce the transfer of heat and cold through the curtain walls. The polyamide strips can also be coated with powder or anodized. All of these would further ensure that the curtainwalls are fit even to counter the harsh weather, which includes fierce cyclones, damaging UV rays, regular corrosion, and more.

How does PA extruder work?

The plastic extrusion process begins when PA compounds in the form granules are continuously fed through a hopper into the extruder. The screw gradually moves these materials along the barrel, and in the process, enough heat is generated to melt the PA compounds.

What is the basic principle of extrusion?

The basic mechanics of extrusion are simple—a screw turns in a barrel and pushes the plastic forward. A screw is really an inclined plane, or ramp, wound around a central core. The intent is to multiply the force so that a great resistance can be overcome.

What is extruder in polymer processing?

Plastic extrusion is a continuous high volume manufacturing process in which a thermoplastic material is homogeneously melted and then forced out of the shaping die by means of pressure. There are different types of an extruder.

The extruder we sell is single screw extruder for the production of PA thermal barrier profiles.

What is the function of plastic extruder?

Plastics extrusion is a high-volume manufacturing process in which raw plastic is melted and formed into a continuous profile. Extrusion produces items such as pipe/tubing, weatherstripping, fencing, deck railings, window frames, plastic films and sheeting, thermoplastic coatings, and wire insulation.

The extrusion produces items of our plastic extruder is thermal break polyamide strips.

What is the purpose of extrusion machine?

Extrusion is a technique where molten polymer is forced through a die and is used to produce components of a fixed cross-sectional area such as polyamide thermal break profiles.

What plastics can be extruded?

There are more than 20 different types of thermoplastics that can be extruded. Some of the more common ones include polyethylene, polypropylene, polystyrene, polycarbonate, PVC and ABS, all of which can be easily heated and then pressured in a mould to form different plastic profiles, tubes and sections.

But we mainly sell PA6.6 gf25 heat insulation profile extrusion machine.

How does extruder work?

An extruder is basically a screw pump. The screw rotates in a tightly fitting stationery barrel. The plastic granules are introduced into the extruder, usually at a constant rate of mass or volume employing a feeding mechanism. The plastic granules thus moves forward by the rotation of the flighted screw.

What are the advantages of plastic extrusion?

The extrusion process is fast and efficient at producing continuous shapes in varying lengths. Products can be produced in large volumes, and there is minimal wastage. Complex shapes can be produced with varying thickness, textures, colors etc.

What is the purpose and benefit of extrusion technique?

The extrusion process also offers an excellent surface finish to parts and gives considerable freedom to form in the design process. Extrusion processes are similar to drawing, which uses the tensile strength of the material to pull it through the die. The drawing process is used to produce wire, bars, tubes and profiles.

Machine Characteristic:

1. The barrel is heated by stainless steel heater, withstand voltage 400V

2. The professional dryer makes raw material convection with hot air uniformly, and the drying uniformity is good. Its thermal insulation structure prevents heat dissipation and promotes energy saving.

3. Special new screw make sure the machine has low energy consumption, good plasticizing ability and stable extrusion flow.

4. The extruder uses high-quality carbide twin-screws to ensure high plasticization of PA66GF25 granules

5. One temperature control zone controlled by one table, and the temperature accuracy can be controlled at ±1℃.

FAQ

Q: What is your MOQ for the polyamide strip extrusion machine?

A: 1 set.

Q: As new player of polyamide strips extrusion, how we learn to use the machine?

A: Polywell will provide paper and videos files to help customer operate the machine. If customer needs, we can also provide on site training service.

Q: Can we customize and buy the raw materials and molds?

A: We can provide every product related to the polyamide thermal break profiles production. Including the raw material, the mold, the cutting machine, the worktable, the winder and so on.

Q: What is the warranty for your machine?

A: For extruder machine, it is one year. We are confident in our products, and pack them well before delivery, so usually you will receive your order in good condition. Any quality issue, we will deal with it immediately.

Q: What is your payment terms?

A: 50% T/T deposit before production, 50% T/T balance before loading.

Our Service

One to one consulting service.

Experienced senior engineer to discuss technical data, designed drawing.

Perfect arrangement of sea or air transport.

Overseas aftersales service.

Professional engineers team.

Welcomed to visit the factory at any time.

Choosing Polywell means choosing the certainty of a reliable partner, able to team up and offer daily support. We are where you need us, whenever you need us.

|

Production Speed |

Around 8-14cm/min |

|

Strip Shape |

All kinds of shape |

|

Raw Material |

PA6.6 granules reinforced by 25% glass fiber |

|

Cooling |

Water Cooling |

|

Usage |

Produce thermal break strip |

|

Type |

Plastic extrusion machine |

|

Winding Machine |

Available |

|

Cutting Machine |

Available |

|

Worktable |

Available |

PA66GF25 Polyamide Profiles Extrusion Machine Including:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

EN

EN