Usage: Industrial / Household / Engineering Plastics / Construction material

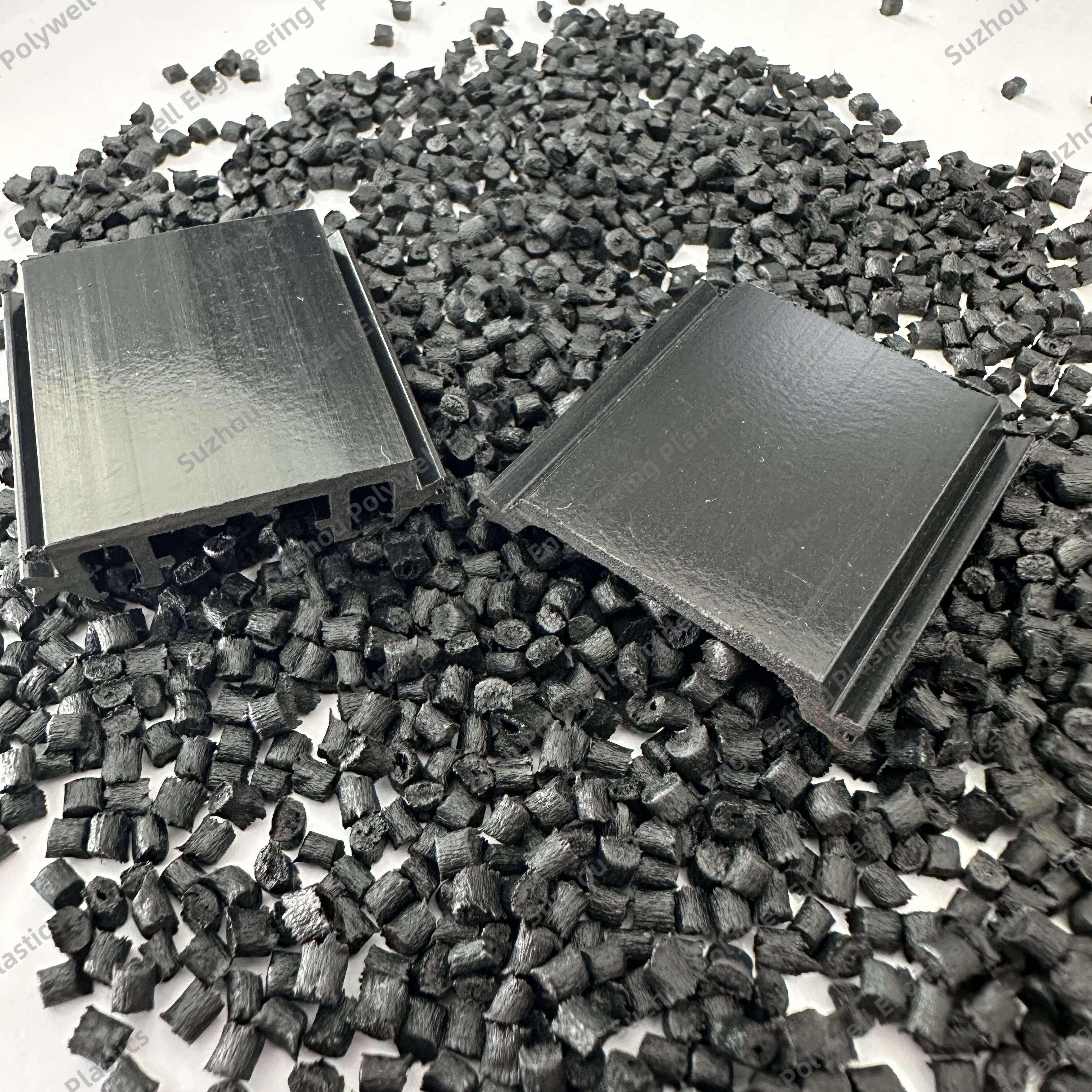

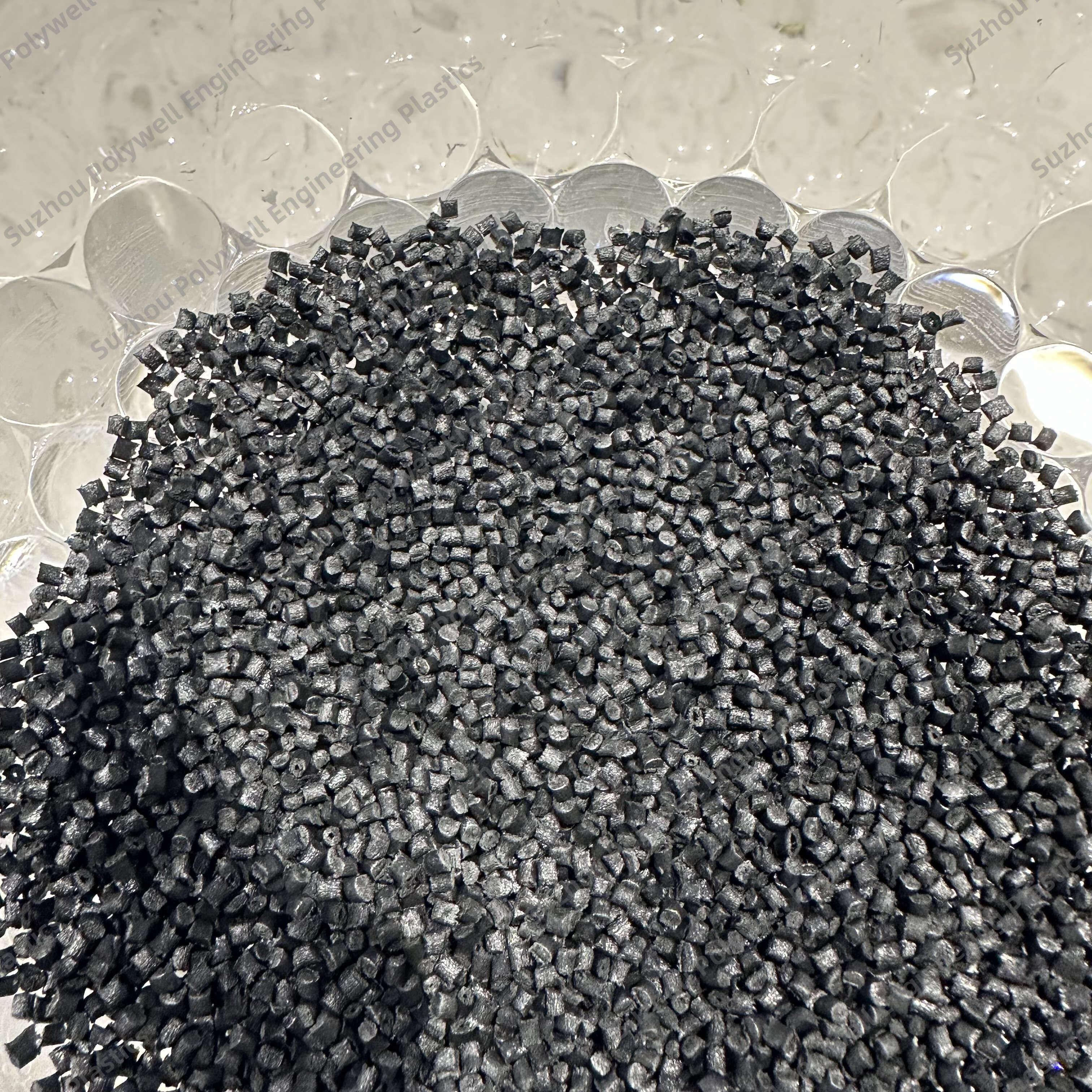

Product Categories: FRP Granules

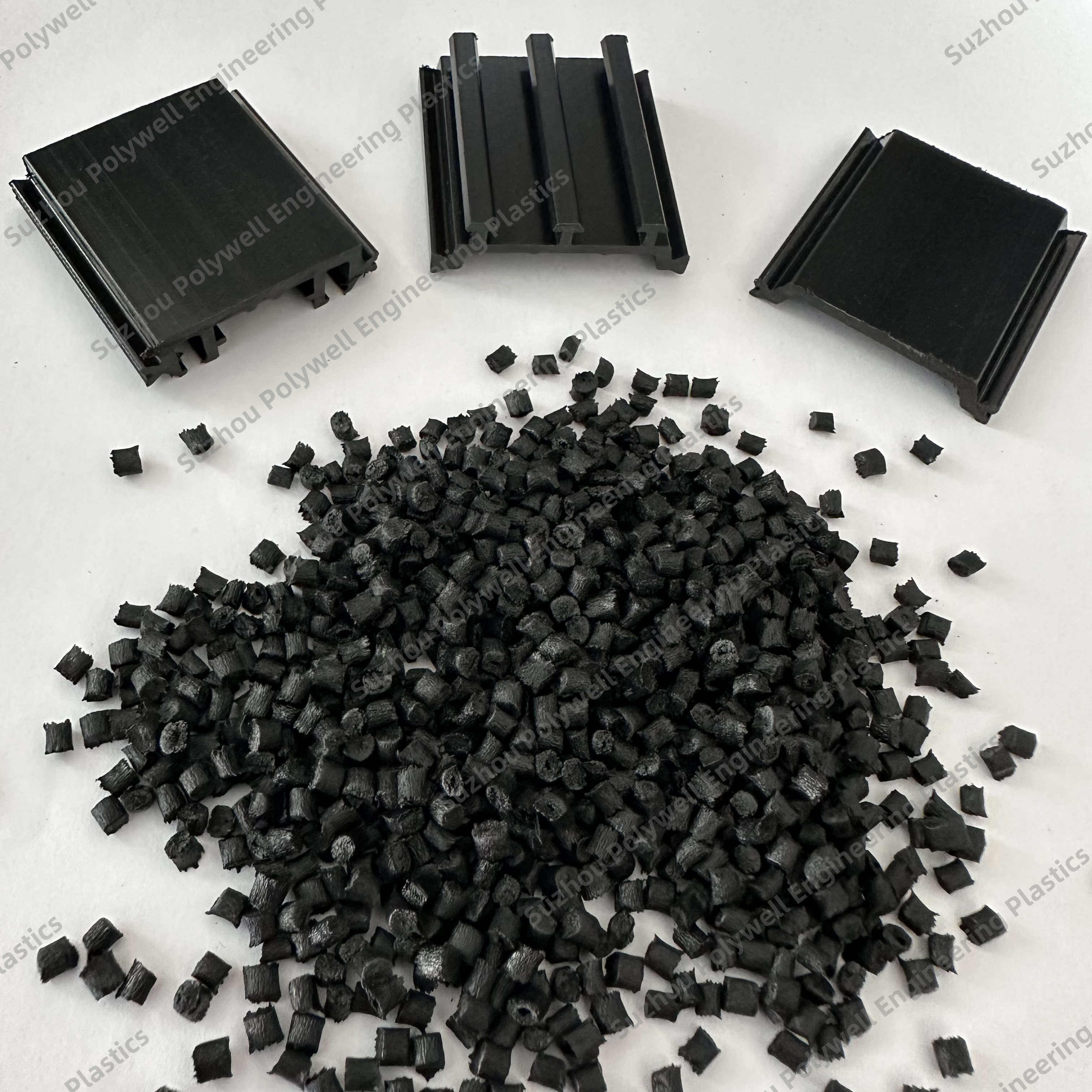

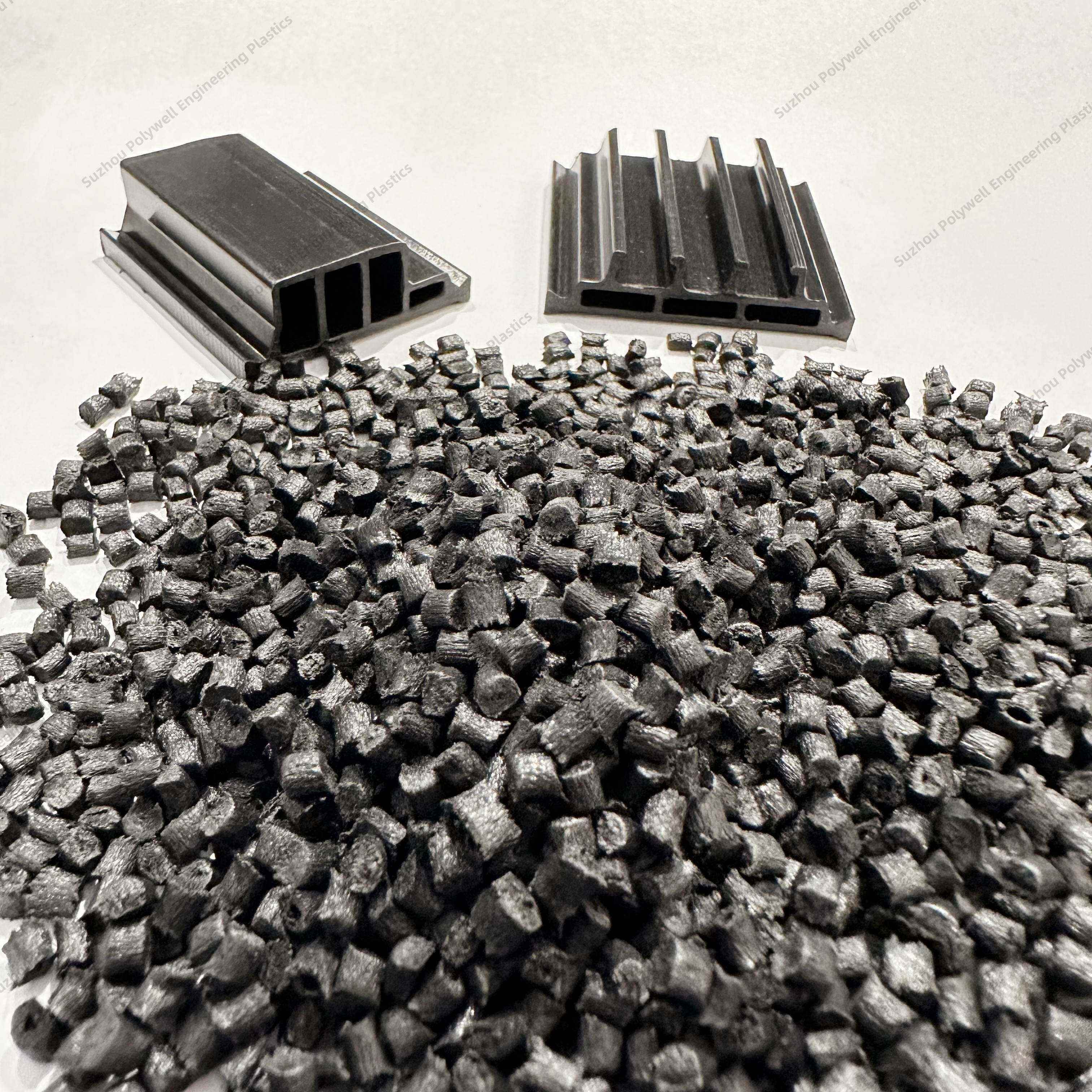

Molding Method: Extrusion

Material: Granules / Pellets / Particles

Fiber Type: GFRP

Type: Polyester FRP

Technical Performance: GB/T 23615.1-2009 / GB/T 23615.1-2017

Fiber Type: Glass fiber reinforced

1. It has excellent mechanical properties, high strength, high toughness.

2. The material has excellent coloring ability, can achieve various requirements of color matching

3. The shrinkage rate of PA66 is between 1% and 2%. The addition of glass fiber additives can reduce the shrinkage rate to 0.2%~1%. The shrinkage ratio is large in the flow direction and in the direction perpendicular to the flow direction.

4. PA66 is resistant to many solvents, but is less resistant to acids and other chlorinating agents.

5. PA66 excellent flame retardant performance, by adding different flame retardants can achieve different levels of flame retardant effect.

Glass-filled nylon is a synthetic polyamide thermoplastic and it's one of the most important materials used in engineering thanks to its strength and heat resistance. It's made by adding powdered glass to nylon resin or by extruding the plastic with glass fibers.

What is raw material for polyamide thermal break strips?

Polyamides are among the most important and proven technical thermoplastics, known for their heat resistance, stiffness and high mechanical stability.

Polyamides can be classified into different types, with PA 6, PA 6.6 and PA 12 most established on the market. Alongside ABS and PP compounds they are among the most widely used plastics, found across several sectors including the automotive, mechanical engineering, structural and installation engineering, photovoltaics and electrical engineering industries.

Glass fiber is a material consisting of numerous extremely fine fibers of glass.

Glass fibres are used as reinforcement of polymers in various fields such as aerospace, automobile, marine, sporting and leisure goods, and construction and civil engineering. One of the principal advantages of using glass fibres for reinforcement of polymers is their high performance per cost ratio.

Our company use PA 6.6 and glass fiber to produce PA66GF25 granules, which is the most suitable raw material for polyamide thermal break strips production.

Polyamides offer high levels of heat resistance, stiffness and high mechanical stability for a durable solution. Our special glass fiber reinforced PA 66 GF25, dry impact resistant mixture is ideal for the production of structural and reinforcement profiles.

Offering excellent heat resistance, polyamides can be used in the toughest of conditions, for example exposure to hot and humid environments. PA profiles can drastically reduce the Utj (U-Value of a thermal joint), which insulates the energy flow from the outside of the facade to the inside.

The uncomplicated processing of polyamides is another key benefit. With various properties that can be individually adapted according to the specific project and need, polyamides are the perfect choice for the manufacture of special extrusion profiles.

Our company has devoted more than ten years to the research and development and production of nylon extruding profiles. According to customer reaction, using our PA66 granules for production can get high yield, easy start-up, and get less scrap in the early start-up stage. There will be no lack or incomplete of profiles in the production process, thus avoiding material waste, saving customer costs and improving production efficiency.

1. We are a trading company with our own factory

We are professionally manufacturer of special material for polyamide thermal break profiles with over 10 years experience.

2. Good service & Top quality

Most perfect equipment, capable&experienced designers and skilled workers, advanced roduction management experience and strict quality management standard.

3. Quality control

Procedure is inspected and controlled before packing the goods. We ensure every piece of product shipped is good quality.

4. Customized Service

If your application requires something even more special, we will work with you to develop unique formulations to help you create products that will dazzle your customers!

1.high mechanical strength

2.high toughness

3.high softening point

4.good wear resistance

5.self-lubrication

6.long-term work at higher temperatures

7.It has high CTI value , excellent electrical insulation , low smoke and low toxicity characteristics.

The color of our PA66GF25 granules is black, but we also can customize according to customers’ requirements.

Specially used in thermal break strips, thermal bridge, heat insulation bar, etc.

Specially used in thermal break strips, heat insulation bar, thermal insulation profiles, thermal broken bridge window,etc.

The PA66 granules with fiber glass are mainly used in thermal break strips, which are used in aluminum windows and doors.

The PA66 granules with fiber glass are mainly used in thermal break strips, which are used in aluminum windows and doors. Our granules have good fluidity thus guaranteeing your smooth production. The good raw material can reduce the rate of rejects, and can produce high quality strips.

|

|

EN

EN