Энерги утгыг хэмжих материал бий болгох шаардлагатай байдал нь ихэвчлэн хөрш орчин үеийн технологийн төлөвлөгөөнд оролцож байна. POLYWELL нь давхаргах цагаан дэлгүүр бүтээх аж ахуйн нэг бөгөөд энэ нь давхаргах дэлгүүрүүдийн сонирхолтой дизайны хувьд хөрш орчин үеийн стрипүүдийг бүтээхэд зориулагдсан.

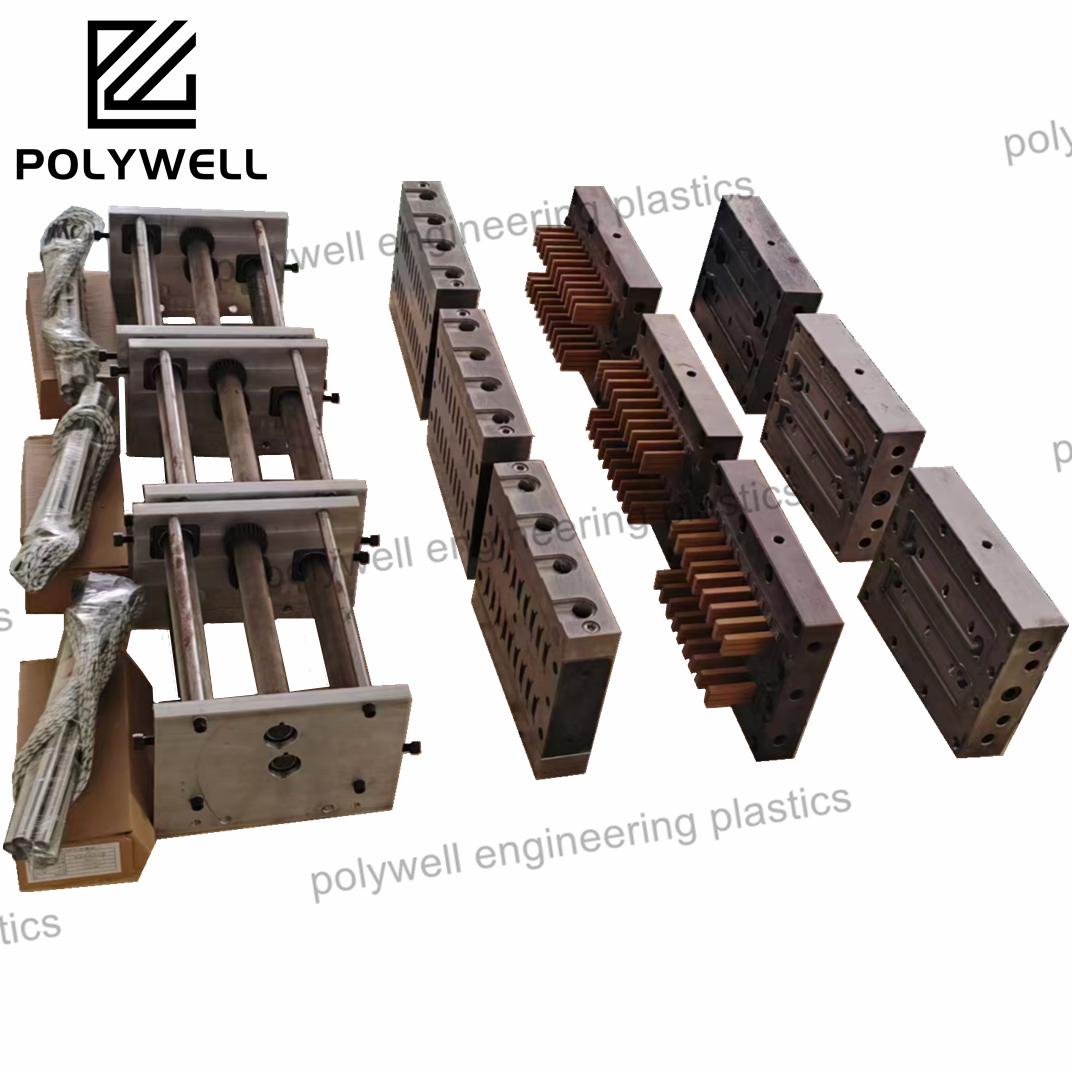

Экструзийн цогц бол хэрэглэгчдийн материалыг экструзийн үйл ажиллагаагаар тогтсон профайл рүү зурахад ашигладаг. Халуун байршуулга хавтаасны дотор экструзийн цогцын чиглэл нь халуун байршуулгын хөндлөнгөөрөө хамгийн ихэнх утгыг хадгалах, эсвэл халуун байршуулгын хувьд суурь тохиргооны хэмжээ, үзүүлэлтийг илүү сайжруулах ёстой. Эдгээр нь анхны үнэт хэрэгслээс хамаарахгүйгээр хамгийн чухал үнэ цэнэ - дуран, холын хэсгүүдийн хооронд оршин тогтноход халуун буусан байдлыг тодорхойлох үнэ цэнэгийг хангахад туслана.

POLYWELL-ийн экструзийн цогцууд яаж ажилладаг вэ POLYWELL-ийн экструзийн цогцуудын зорилго нь халуун байршуулгын хавтааснуудыг хамгийн зөвхөн тохиромжтой байдлаар үйлдвэрлэх, эсрэгээр хамгийн их санд хэрэглэгчдийн материалыг ашиглахгүй байх юм. Эхлээд термопластик эсвэл шинжний материал нь хамгийн ихэнх утгыг хадгалж, хамгийн ихэнх утгыг хадгалахдаа хамгийн ихэнх утгыг хадгалах ёстой. Дараа нь материал цогц руу орж, хавтаасны хувьд хамгийн ихэнх утгыг хадгалахдаа хамгийн ихэнх утгыг хадгалах ёстой.

Эрдэнэ хиймэл: POLYWELL-ын үйлдвэрлэсэн эрдэнэ хиймэл нь цонх болон дархадын бага хоорондхийг зөвхөн нэг нэгтгэлтэйгээр шугамшсан.

Хоосон хиймэл: Энэ хиймэл нь шугамд өөр өөр материалуудыг оруулж, мөн үзэгдлийг нэмэгдүүлэх, өнгөөрөө өөрчилөх эсвэл текстуртай болгох зорилготой.

Халуун хиймэл: Халуун хиймэл нь зөвхөн хашаандаа тусгаарлагдаж болохгүй материалуудыг үйлдвэрлэхэд ашигладаг, эсвэл тухайн барааны үнэ цэнэтэй холбогдох үндсэн байдлыг хангахад ашигладаг.

POLYWELL-ын эрдэнэ хиймэл юуны тулд шугамшсан эрдэнэний үйлдвэрлэлд тодорхой байдал

Дотоод: Үйлдвэрлэгчид хиймэл ашиглан гаргасан үр дүнтэй шугамшсан эрдэнэ нь стандарт хэмжээнд бүтээгдэхүүн болон үнэ цэнэтэй холбогдох хамгийн сайн стандартыг хангахад зориулж байна.

Зөвлөмжийн хамгийн их боломж: POLYWELL-ын бүх цуглуулагчид нь үйлдвэрлэлийн өөр төрлийн thermic break стрипүүдийг үйлдвэрлэхэд зориулсан үйлчилгээнд харьяалагдахад зориулагдсан бөгөөд үйлчилгээнд эргэцтэй цуглуулагч сонгох магадлалыг олгодог.

Ажиллах хурд: Extrusion molding технологийн ашиглалт нь материал ашиглах хэмжээг бууруулж, үйлдвэрлэлийн үйл ажиллагааны үнэ цэнэтэй харьцуулахад тусалдаг, эсвэл орчин үеийн байгалийн хамгааллын хувьд илүү сайн.

Барилгын салбарын дээд өсөлт нь thermic break стрипүүдийг үйлдвэрлэхэд зориулагдсан POLYWELL-ын ихээхүүн extrusion цуглуулагчдын дизайнуудтай холбоотой. Энерги урамшуулалын хувьд бараа материалын үнэ цэнийг бууруулахад тусалж, үйлчилгээнд хамгийн сайн бүтээгдэхүүнүүдийг олгодог. Base, injection эсвэл cold molds-уудын аль нь ч шаардлагатай бол POLYWELL зөв хариулт юм.