Ашиглалтын үед ихэнхээсээ амаршан болгох, зорчих зам буюу шилжүүлэгчийн мөрдөгчийг зохион бүтээхэд томъёоны үндэслэл, зорчих замын шинж чанар, эрэлттэй байдлыг анхаарах ёстой. Энэ нь амаршан болгох замын хамгийн сайн үйл ажиллагаагаар зохион байгуулагдсан бөгөөд амаршан болгох зам, эрэлттэй байдлыг хангахад POLYWELL-ийн шилжүүлэгчийн мөрдөгч ашигладаг.

Энэ үед, амьдрахад их хэрэгтэй болсон тэнцвэрчилсэн цагаан босоо нь эрдэнэ хэмжээнд зориулж байгаа үйлдвэрлэлийн үр дүнд нэвтрэх замуудын хамгийн чухал хэсэг юм. Энэ нь POLYWELL-ийн тэнцвэрчилсэн цагаан босоог ашигладаг. Тэдгээрийг дараа нь төгсөгчөөр шигдүүлэн, хэрэглэгчийн уртанд харьцуулахад зориулагдсан урттайгаар гуравчлан хувааж байна. Мөн тэнцвэрчилсэн цагаан босоо нь тэнцвэрчилсэн орчин үзүүлэх, дулааны хөдөлгөөнтэй замуудыг хязгаарлахад ихээр томъёолно.

Ашиглахдаа экструзийн үйл ажиллагааг дагах ёстой:

Эхлээд хувуурч: Резин эсвэл термопластик гэх мэт үндсэн материалыг хувуурч, мөргөхөд зөвлөхөд зориулж байна.

Дагаад мөрдөг: Сүүлийн үед мөрөөдөг резингийг бүтээгдэхүүний мөрөөдөлд хүртээхээр резингийг өөртөө хэрэгтэй байдлын дагуу хэлбэрлүүлэх боломжтой.

Хоолдоод хуваах: Материал экструзийн үеэр гарч ирсэн дараа хоолдог, хэрэглэгчийн шаардлагатай уртанд хувааж байна.

POLYWELL-ын Экструзийн Моделүүдийн Үндсэн Хамгаалагдсан Зорилго Нь POLYWELL-ын экструзийн моделүүдэд холбогдох бага зэрэг ач тус байдаг, энгийн нь үйлдвэрлэлийн үед цаг агаарын шугамуудыг ашиглахад амжилттай болон дотоод тохиромжтой байх ёстой. Эдгээр нь POLYWELL-г бусад компаниудаас ялгаруулдаг нь:

Тогтвортой Гаралтын Тухай: POLYWELL-ын моделүүд нь тогтвортой байдлыг хамгийн ихээр хангахыг зорьж бүтээгдсэн бөгөөд ганцхан шугамын хэмжээ, хэлбэр болон ажиллагаа нь хамгийн их хандалттай байдаг. Энэ нь энергийн ашиглалтыг ихэсгэхэд томоохон нөлөөгөөр орсон цаг агаарын шугамыг үйлдвэрлэхэд чухал байдаг.

Хугацаанд Хамгаалагдаж Буй Байршил: Экструзийн моделүүдэд ашигладаг бидний материалууд нь хязгааргүй байдлыг хамгийн ихээр хамгаалдаг бөгөөд экструзийн үйл ажиллагааны стрессийг амжилттай хамгийн ихээр хамгийн ихээр хамгийн ихээр хамгийн ихээр.

Энергийн ашиглалт: POLYWELL-ийн шинэчлэлийн хөрш үйлдвэрлэх технологи доторх алдартай зуурчлагыг багасгаад, барилгын үйлдвэрлэлийн үед материал, энергийн хайдлыг багасгаж, хөрш үйлдвэрлэх стрипүүд нь амтанд татгалзахад ихэвчлэн ашигтай, үйл ажиллагаандаа эрүүл мэндийн хамгаалалтанд нийцэж байна.

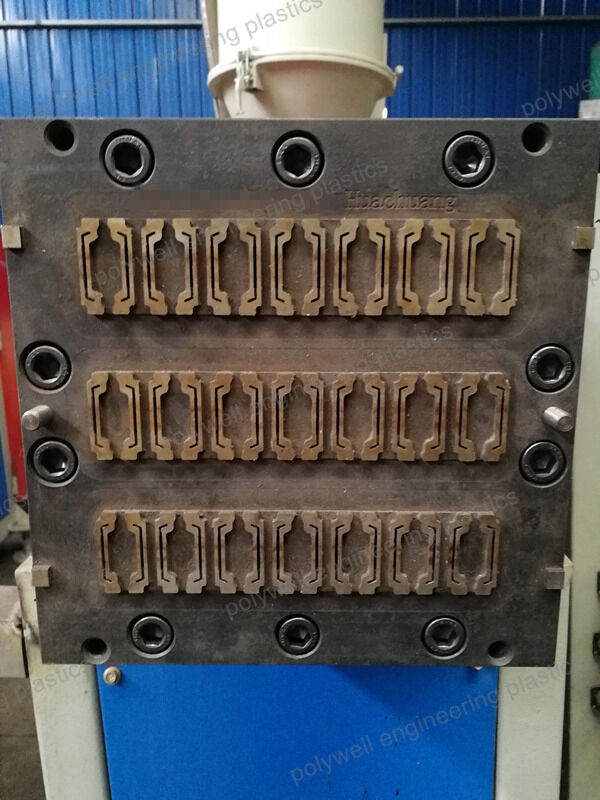

POLYWELL-ийн ашиглах экструзийн цонхнууд Энэ нь POLYWELL-ийн хөрш стрип болгоход ашигладаг олон төрлийн экструзийн цонхнууд юм. Дараах нь тэдний жишээнүүд юм:

Эерэг цонхнууд: Эдгээр цонхнууд нь стрипийн үндсэн хэлбэрийг үүсгэхэд ашигладаг, тиймээс амтанд татгалзах үйлчилгээ ч анхны профайлд нь ижил байдлаар томъёолно.

Инъекцын цонхнууд: Эдгээр нь стрипийн өнгө, текстур, амтанд татгалзах үйлчилгээг нэмэхэд ашигладаг.

Хоолой цонхнууд: Эдгээр цонхнууд нь бага температурт гаднах материалыг ашиглахад ашигладаг, энэ нь үнэхээр томъёолсон үйлчилгээ юм.

Хүчирхэг шугамын босоо хавтангийн үйлдвэрлэлд POLYWELL нь дундаж үзүүлэлт, үр дүнтэй хамгийн сонирхолтой технологийг ашиглахад эрчимтэй. Зарим үндсэн шаардлагуудад тусалж, шинэ технологийг ашигласан molds-ийн төрлүүдийг хэрэглэж байна.