- Saib xyuas

- Cov khoom pom zoo

- Piv txwv dej cov ntsiab lus tsawg dua 0.2% los ntawm qhov hnyav.

- Kev kuaj mob: (23 ± 2) ºC thiab (50 ± 10)% txheeb ze av noo.

- Cov lus qhia tshwj xeeb uas cim "a" tsuas yog siv rau I-shaped strip txwv tsis pub, cov ntsiab lus xaus ntawm tus neeg muag khoom thiab tus neeg yuav khoom los ntawm kev sib tham, yuav tsum tau sau rau hauv daim ntawv cog lus lossis kev yuav khoom.

Khoom piav qhia:

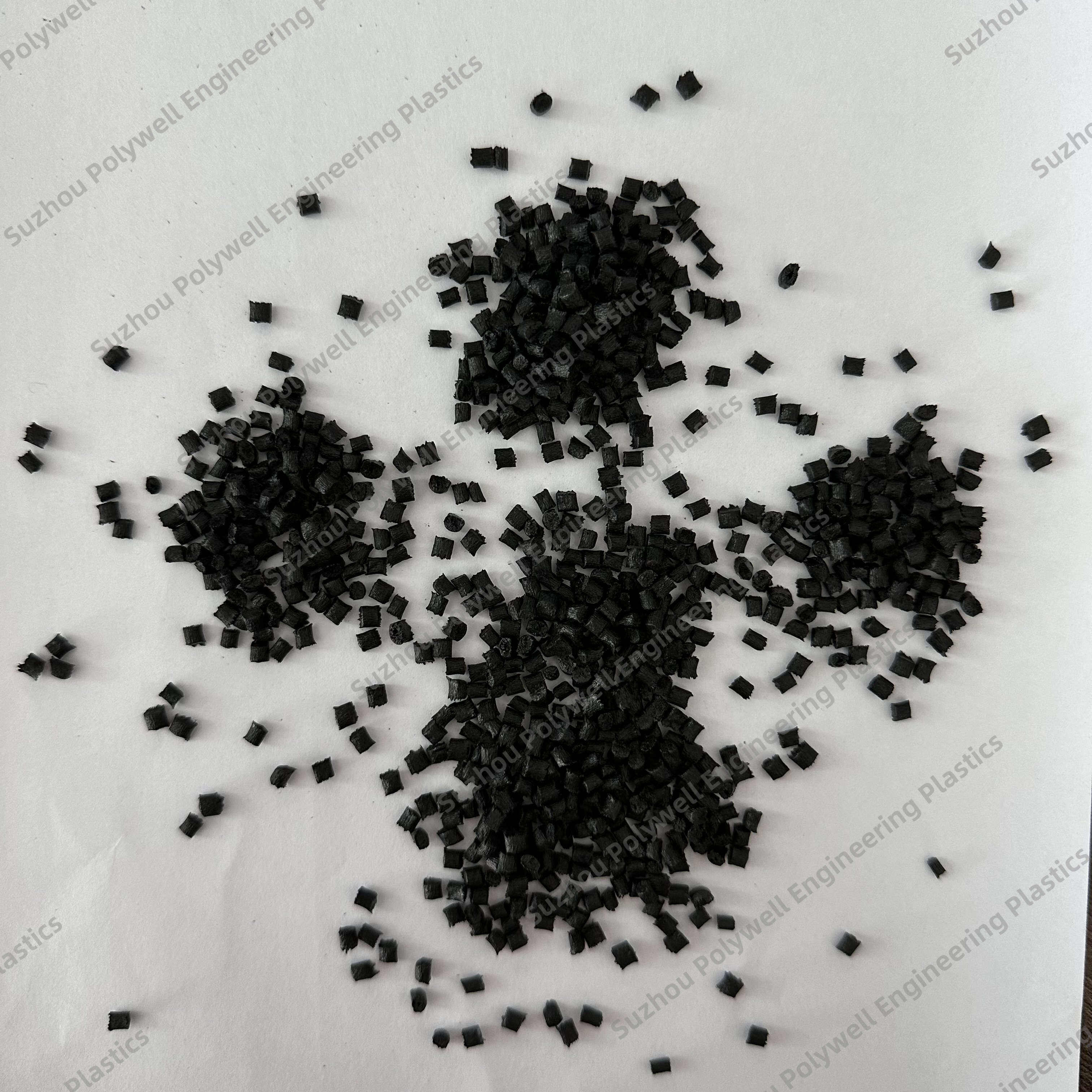

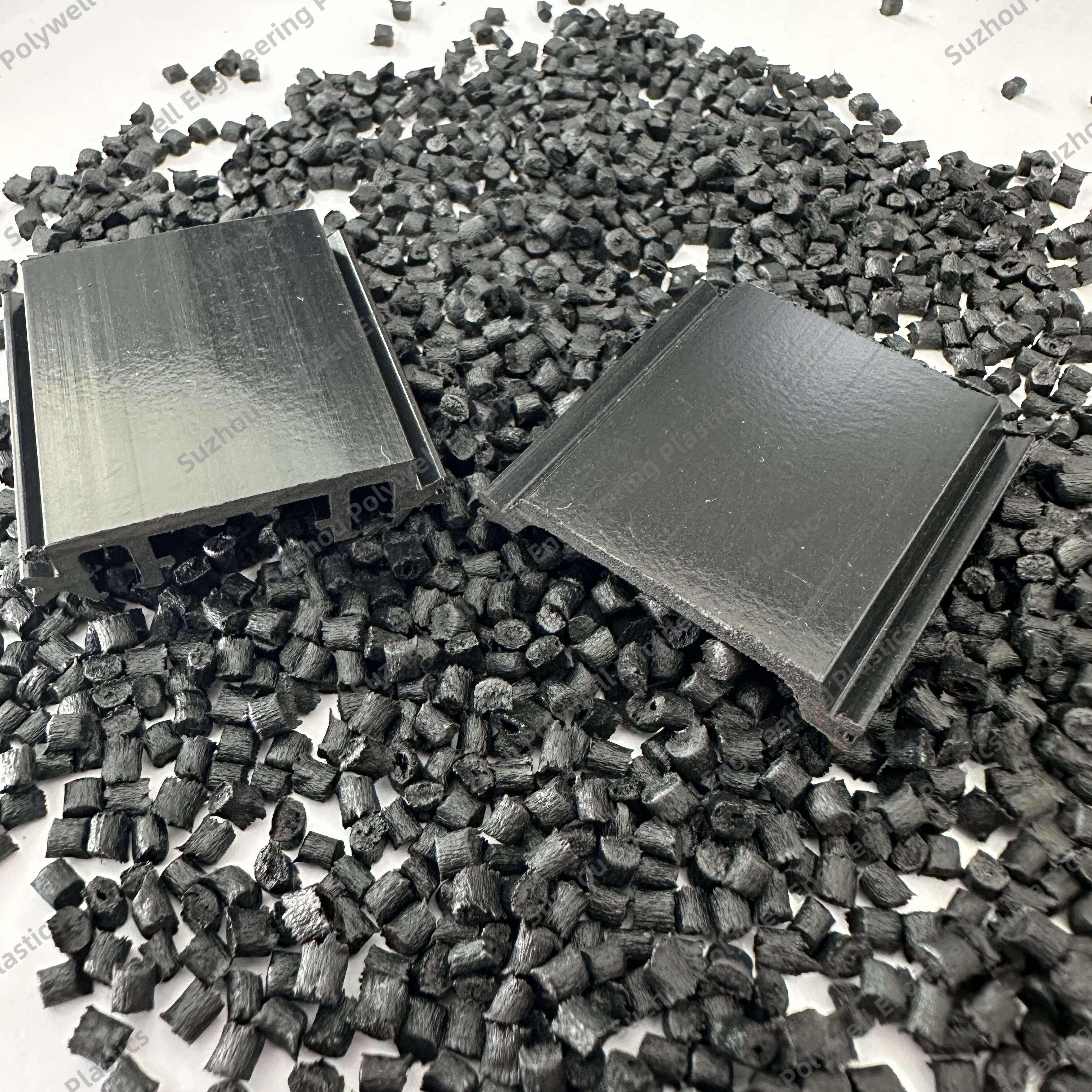

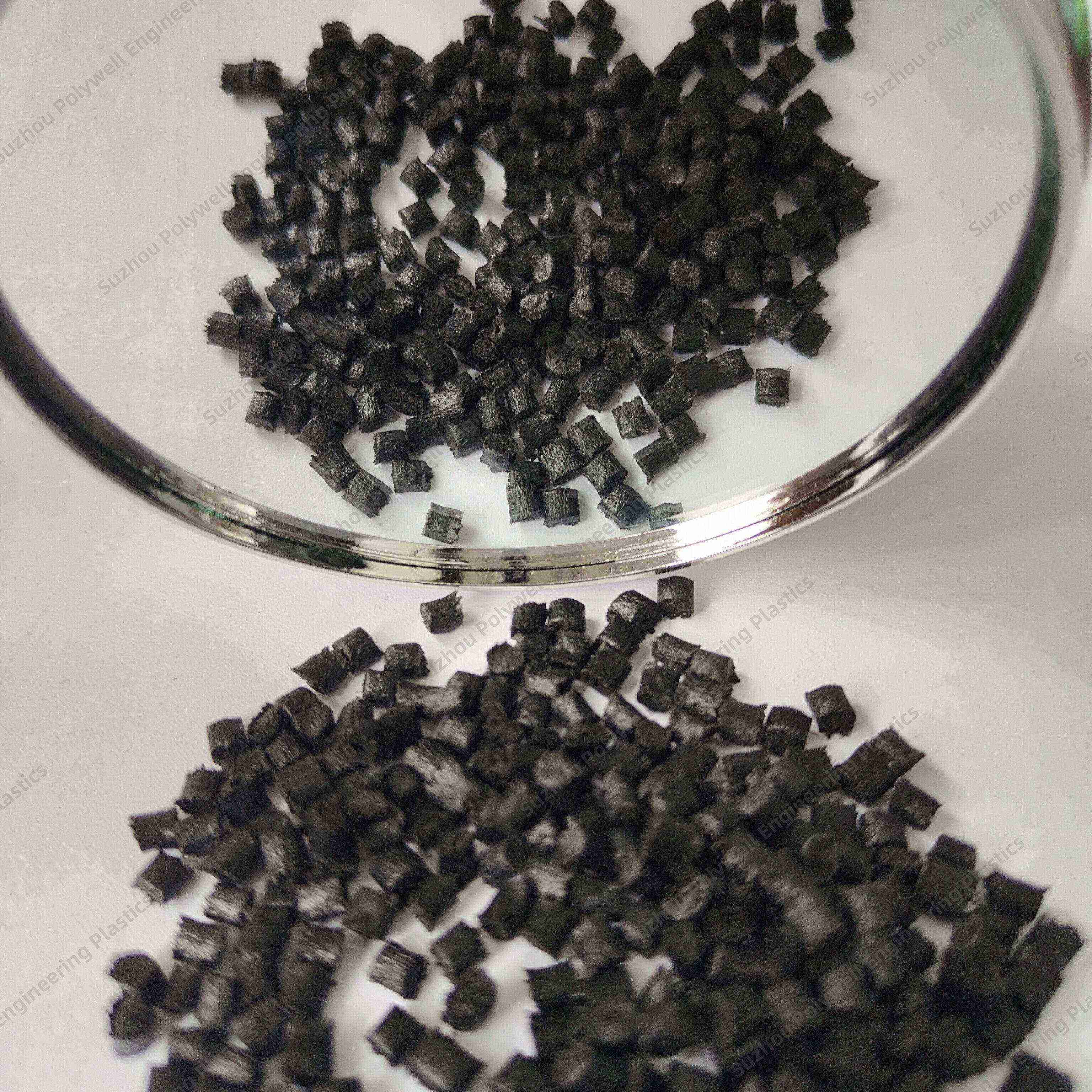

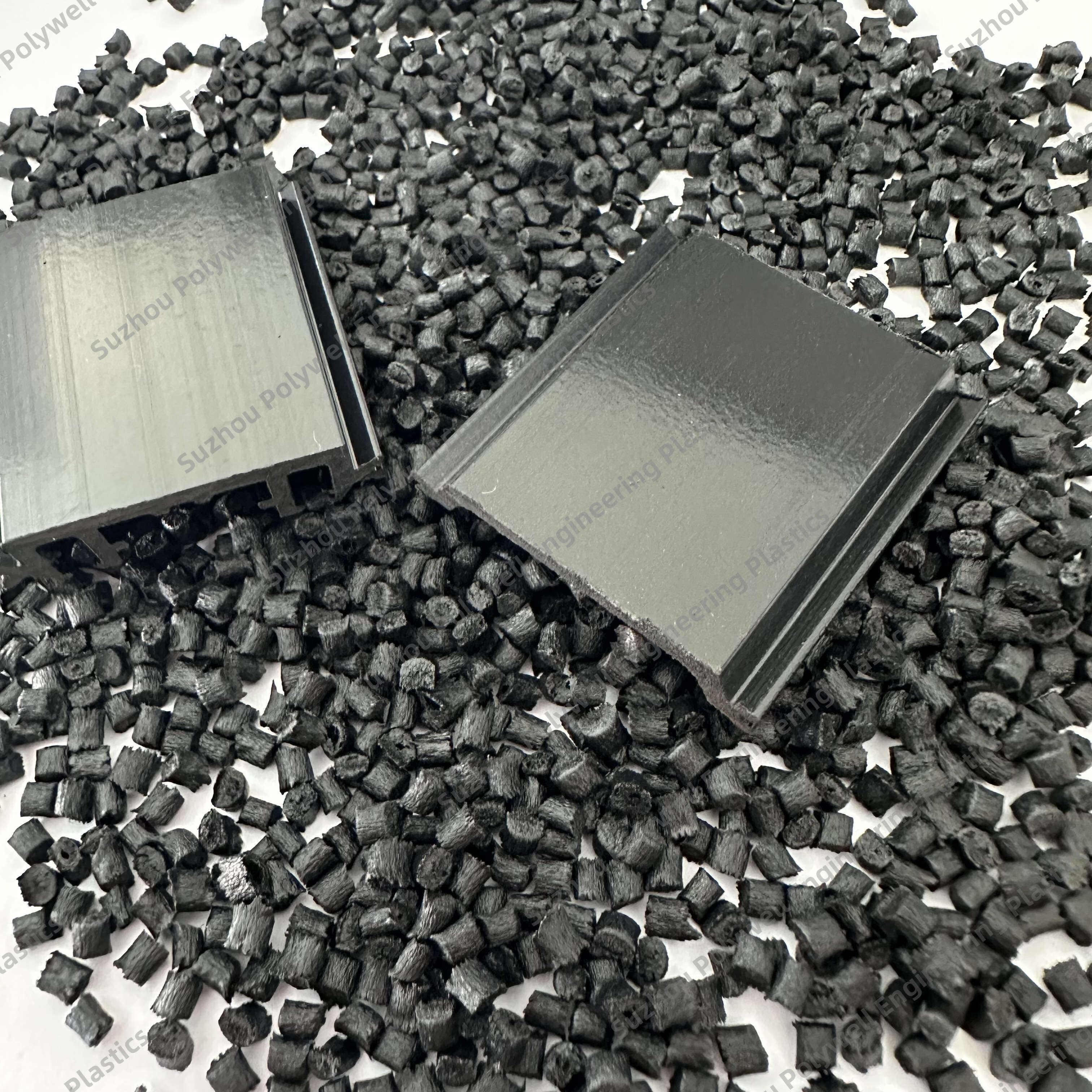

Polyamide 6.6 granules uas tau kho kom zoo los ntawm fiberglass, nrog cov khoom ntxiv tshwj xeeb, yog blended thiab extruded los ntawm twin screw extrusion machine. Nws yog qhov zoo dua rau extrusion ntawm heat insulation strip. Thaum piv nrog cov granules ib txwm, nws yog qhov zoo dua rau forming. Nws muaj qee qhov zoo hauv ceev, qhov chaw tiav thiab yield. Cov kev ua tau zoo ntawm nylon insulating strip tsim los ntawm cov khoom no ua raws li cov qauv ntawm lub teb chaws. Nws tsis tsuas yog tuaj yeem kho raws li cov neeg siv khoom xav tau, dhau ntawm lub teb chaws qauv, tab sis kuj tuaj yeem ntxiv high-efficiency flame retardant kom ua tiav lub hom phiaj ntawm flame retardant.

Taw qhia ntawm Peb PA66GF25 Granules:

Peb PA66GF25 granules yog cov khoom tshwj xeeb rau heat insulation profiles. Nws yog extrusion grade modified plastics. Nws txawv ntawm PA66 resin.

Peb PA66GF25 granules yog reinforced los ntawm 25% glass fiber.

PA66 nta

1. Nws muaj cov cuab yeej zoo heev, lub zog siab, siab toughness.

2. Cov ntaub ntawv muaj kev zoo hauv kev hlav xeeb, tuaj yeem pom cov lus nug sib phim hauv kev hlav xeeb.

3. Tus nqi shrinkage ntawm PA66 yog nyob nruab nrab ntawm 1% thiab 2%. Qhov sib ntxiv ntawm cov iav fiber ntau ntxiv tuaj yeem txo qis qis rau 0.2% ~ 1%. Lub shrinkage piv yog loj nyob rau hauv cov kev taw qhia ntws thiab nyob rau hauv cov kev taw qhia perpendicular mus rau lub ntws kev taw qhia.

4. PA66 tiv taus ntau cov kuab tshuaj, tab sis tsis tshua muaj resistant rau acids thiab lwm yam tshuaj chlorinating.

5. PA66 zoo heev nplaim retardant kev ua tau zoo, los ntawm kev ntxiv cov nplaim hluav taws sib txawv tuaj yeem ua tiav cov nplaim hluav taws kub sib txawv.

Dab tsi yog GF hauv cov khoom siv yas?

Iav-filled nylon yog ib qho hluavtaws polyamide thermoplastic thiab nws yog ib qho ntawm cov ntaub ntawv tseem ceeb tshaj plaws siv hauv engineering ua tsaug rau nws lub zog thiab kub tsis kam. Nws yog tsim los ntawm kev ntxiv cov hmoov iav rau nylon resin los yog extruding cov yas nrog iav fibers.

Dab tsi yog raw khoom rau polyamide thermal so strips?

Polyamides yog ib qho tseem ceeb tshaj plaws thiab muaj pov thawj technical thermoplastics, paub txog lawv cov cua sov ua haujlwm, tawv tawv thiab siab mechanical stability.

Cov xyooj rau hauv lub tswv teb, PA 6, PA 6.6 thiab PA 12 yog mus qhia los yuav tsum nrog tau market. Rau ABS thiab PP compounds, nej cov nyob rau hauv ib tug tsis muaj plastics, ntawd mus rau hauv ib qab lub zos ua hauv tus automotive, mechanical engineering, structural thiab installation engineering, photovoltaics thiab electrical engineering industries.

Glass fiber yog cov lwm qhov no yog li cas qhia qhov daim ntawm tus glass.

Cov iav fiber ntau yog siv los txhawb cov polymers hauv ntau yam xws li aerospace, tsheb, marine, kev ua kis las thiab cov khoom ua si, thiab kev tsim kho thiab kev tsim vaj tsev. Ib qho ntawm cov txiaj ntsig tseem ceeb ntawm kev siv iav fibers rau kev txhawb nqa ntawm cov polymers yog lawv cov kev ua haujlwm siab ntawm tus nqi sib piv.

Tus kompani nws muaj PA 6.6 thiab glass fiber mus paub PA66GF25 granules, Yog cov raws kawg ntawm hauv polyamide thermal break strips production.

Vim li cas thiaj siv polyamide los tsim thermal so profiles?

Polyamides muaj qib siab ntawm cov cua sov ua haujlwm, nruj thiab siab txhua yam kev ruaj ntseg rau cov tshuaj ruaj khov. Peb tshwj xeeb iav fiber reinforced PA 66 GF25, qhuav cuam tshuam resistant sib tov yog zoo tagnrho rau zus tau tej cov structural thiab reinforcement profiles.

Muab cov khoom siv hluav taws xob zoo heev, polyamides tuaj yeem siv rau hauv qhov nyuaj tshaj plaws ntawm cov xwm txheej, piv txwv li raug rau qhov kub thiab av noo. PA profiles tuaj yeem txo qis Utj (U-Nqis ntawm thermal sib koom), uas ua rau lub zog ntws tawm ntawm sab nraud ntawm lub ntsej muag mus rau sab hauv.

Kev ua haujlwm tsis yooj yim ntawm polyamides yog lwm qhov txiaj ntsig tseem ceeb. Nrog ntau yam khoom uas tuaj yeem hloov kho tus kheej raws li qhov project tshwj xeeb thiab xav tau, polyamides yog qhov kev xaiv zoo tshaj plaws rau kev tsim khoom tshwj xeeb extrusion profiles.

Hais txog xim:

Cov xim ntawm peb PA66GF25 granules yog dub, tab sis peb kuj tuaj yeem kho raws li cov neeg siv khoom xav tau.

Daim ntawv thov:

Tshwj xeeb siv hauv thermal break strips, thermal bridge, heat insulation bar, thiab lwm yam.

Package thiab Delivery:

Ntim cov ntsiab lus |

25 kg / hnab |

Lub sijhawm ua haujlwm |

10-15 hnub ua haujlwm |

Cov ntaub ntawv xa tuaj |

10-16 tons ib 20 feet contai ner 20-25 tons rau 40 feet thawv |

FAQ:

Q: Txog Qauv

A: Qauv yog dawb, tab sis tus nqi xa khoom yog sau. Cov neeg siv khoom kuj tuaj yeem xaiv lawv tus kheej koom tes courier tuam txhab.

Q: Txog MOQ

A: Rau polyamide granules, MOQ yog 1 tuj. Rau cov thermal so strips, MOQ yog 5,000 meters.

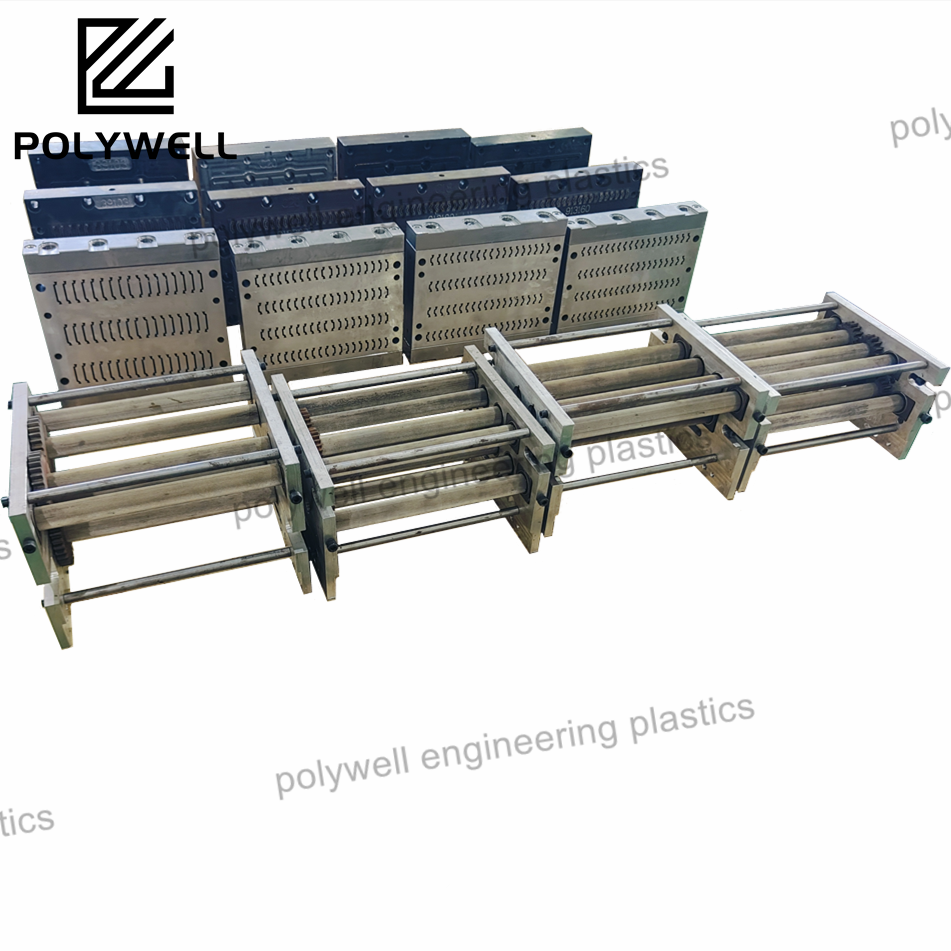

Q: Txog Customizing Tshwj Xeeb Zoo Ntawm Polyamide Profiles Thiab Nws Lub Sij Hawm

A: Koj tuaj yeem kho cov duab tshwj xeeb ntawm polyamide strips. Yog tias peb tsis ua raws li cov qauv no ua ntej, peb yuav ua pwm tshiab rau koj, thiab cov neeg siv khoom xav tau them nyiaj rau pwm.

Q: Txog Customizing Package Style thiab Marks

A: Koj tuaj yeem kho lub pob style thiab cov cim.

Q: Vim li cas koj tus nqi siab dua / qis dua lwm tus?

A: Rau xyoo specializing hauv polyamide granules thiab thermal break strips tau muab rau peb cov neeg ua haujlwm muaj kev paub thiab muaj peev xwm thiab cov neeg ua haujlwm tsim khoom. Peb cog lus txog kev ruaj ntseg ntawm cov khoom thiab qhov zoo ntawm cov khoom raw. Tsis tas li, peb tuaj yeem muab kev txhawb nqa thev naus laus zis los ntawm cov khoom raw mus rau cov khoom siv kawg.

Q: Hais txog warranty

A: 1 xyoos. Peb muaj kev ntseeg siab rau peb cov khoom, thiab ntim lawv zoo ua ntej xa khoom, yog li feem ntau koj yuav tau txais koj qhov kev txiav txim zoo. Txhua qhov teeb meem zoo, peb yuav daws nws tam sim ntawd.

Q: Txog Kev Them Nyiaj lossis lwm yam lus nug

A: 50% T / T tso nyiaj ua ntej ntau lawm, 50% T / T tshuav nyiaj li cas ua ntej thauj khoom.

Product Performance

Khoom |

Chav tsev |

GB/T 23615.1-2009 |

PW-Technical specification |

Qhov ntom |

g/cm3 |

1.3 ± 0.05 |

1.28-1.35 Nws |

Linear expansion coefficient |

K-1 |

(2.3-3.5) X 10 -5 |

(2.3-3.5) X 10 -5 |

Vicat softening kub |

ºC |

≥230 |

≥233 |

Melting point |

ºC |

≥240 |

≥240 |

Kev ntsuas tensile tawg |

- |

Tsis muaj kab nrib pleb |

Tsis muaj kab nrib pleb |

Ntug hardness |

- |

80 ± 5 |

77-85 : kuv |

Kev cuam tshuam lub zog (tsis suav nrog) |

KJ/m2 |

≥35 |

≥38 |

Tensile zog (longitudinal) |

MPa |

≥80 ib |

≥82 ib |

Elasticity modulus |

MPa |

≥4500 |

≥4550 |

Elongation thaum so |

% |

≥2.5 |

≥2.6 |

Tensile zog (transverse) |

MPa |

≥70 ib |

≥70 ib |

High kub tensile zog (transverse) |

MPa |

≥45 ib |

≥47 ib |

Tsawg kub tensile zog (transverse) |

MPa |

≥80 ib |

≥81 ib |

Water resistance tensile zog (transverse) |

MPa |

≥35 ib |

≥35 ib |

Aging resistance tensile zog (transverse) |

MPa |

≥50 ib |

≥50 ib |

EN

EN