Polyamide Extruder Equipment Nylon Yas Bar Sib Sau Tshuab Ib Screw Yas Extrusion Ntau Lawm Kab

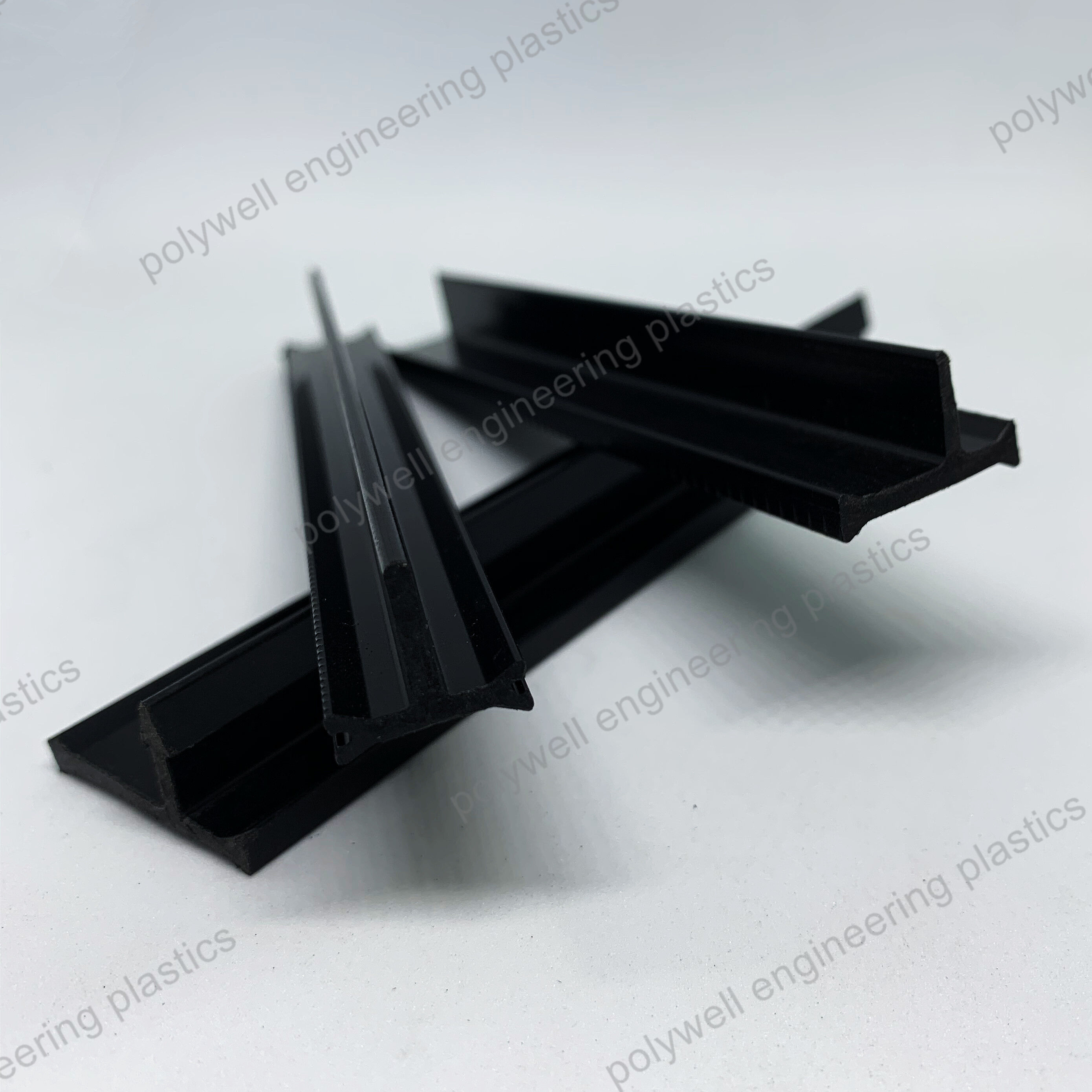

Tsheb Extrude Chain Guide Nylon Runway Guide Rial Guide

- Saib xyuas

- Cov khoom pom zoo

- Tsis siv neeg pub noj tshuab

- Hopper tshuab ziab khaub ncaws

- Lub tshuab extrusion PA strip tseem ceeb

- Pwm / cuab yeej / Tuag

- Txiav tshuab

- Fixture ntaus ntawv

- Txiav tshuab

- Lub rooj ua haujlwm

- Tshuab winding

Kev Pabcuam Tomqab Muag: Cov Kws Ua Haujlwm Muaj Kev Pabcuam Txawv Tebchaws

Warranty: 1 Xyoo

Hom: Profile Extruder

Cov txheej txheem yas: PA66-gf

Yam khoom: Profile Extrusion Moulding Tshuab

Yam khoom: PA profile

Pub hom: Ib Pub

Cov qauv sib dhos: cais hom Extruder

Ntsia Hlau: Ib-Screw

Kev sib koom ua ke: Tsis-intermeshing

Screw Channel Structure: Deep Screw

Exhaust: Tsis txhob Exhaust

Automation: Tsis siv neeg

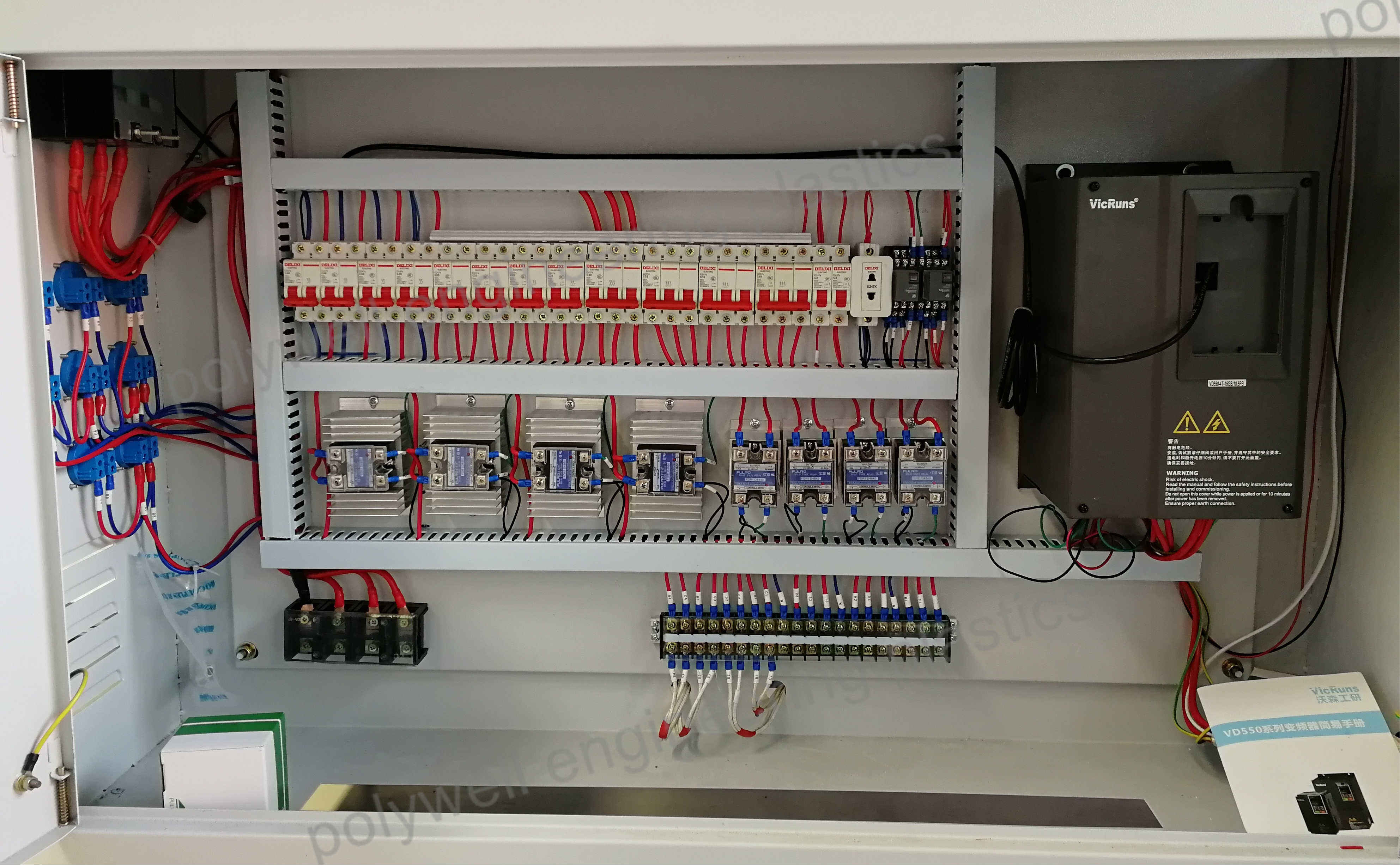

Computerized: Khoos phis tawj

Thauj Pob: Yas Ua Npuas Ncauj Zaj Duab Xis lossis Plywood Case

Specification: 60mm / 70mm / 80mm

Trademark: Polywell

Keeb kwm: Zhangjiagang City, Suav teb

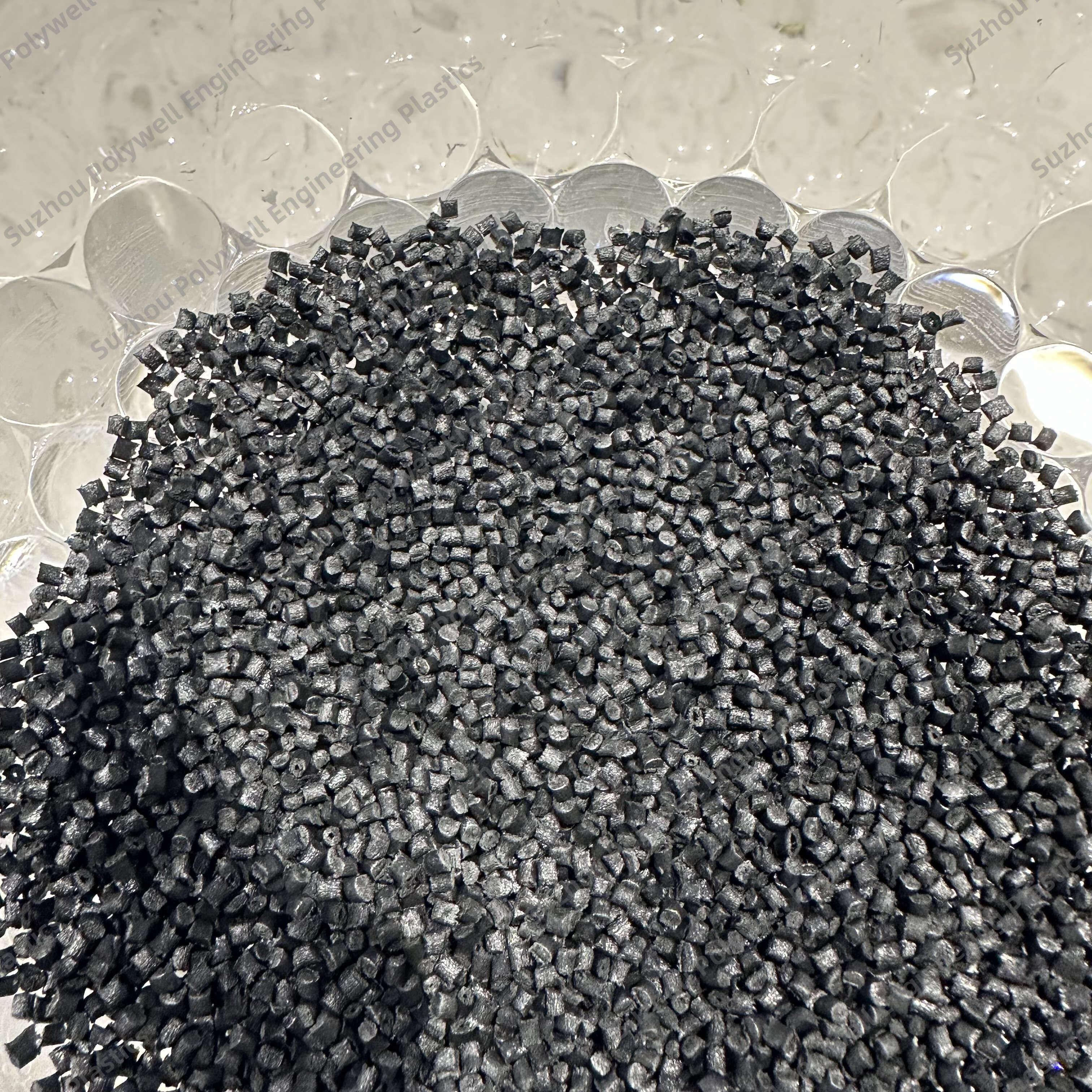

Khoom siv: Polyamide, iav fiber

Kev Siv: Ua Polyamide Strips

Cov Khoom Siv Yas Tom Qab Kub: Thermoplastic Plastics

Plastic txoj kev: Extrusion

Daim Ntawv Thov: Thermal Break Aluminium Profiles Ntau Lawm

Lub Zog: 15-20kw

Qhov hnyav: 900-1000 kgs

Ceev: Nyob ib ncig ntawm 8-14 cm ib min

Tsim nyog Sawb Shape: Txhua Hom Zoo

HS code: 847720

Muaj Peev Xwm Ntau Lawm: 40-50 teeb ib hlis

Customized: Customized

Polyamide Thermal Strip Processing Txheej txheem

PA66GF25 granules yog qhuav thiab nkag mus rau hauv lub tshuab chim los ntawm lub hopper. Cov granules nyob rau hauv kev sib cuag nrog lub tshuab ntsia hlau, thiab txav mus rau lub pwm nrog kev sib hloov ntawm cov ntsia hlau.

Raws li qhov sib txawv ntawm lub tshuab ntsia hlau thiab lub thoob yog me me, cov granules yog rhuab nyob rau hauv qhov sib txawv nyob rau hauv tus txheej txheem ntawm mus rau pem hauv ntej. Lawv yog plasticizied rau nylon molten xeev los ntawm qhov kub siab ntawm hluav taws xob cua sov nplhaib lub cev. Lub xeev molten ntawm nylon yog hloov mus thiab zoo li tus tom qab nkag mus rau hauv pwm, thiab thaum kawg extruded rau hauv tshav kub rwb thaiv tsev strips.

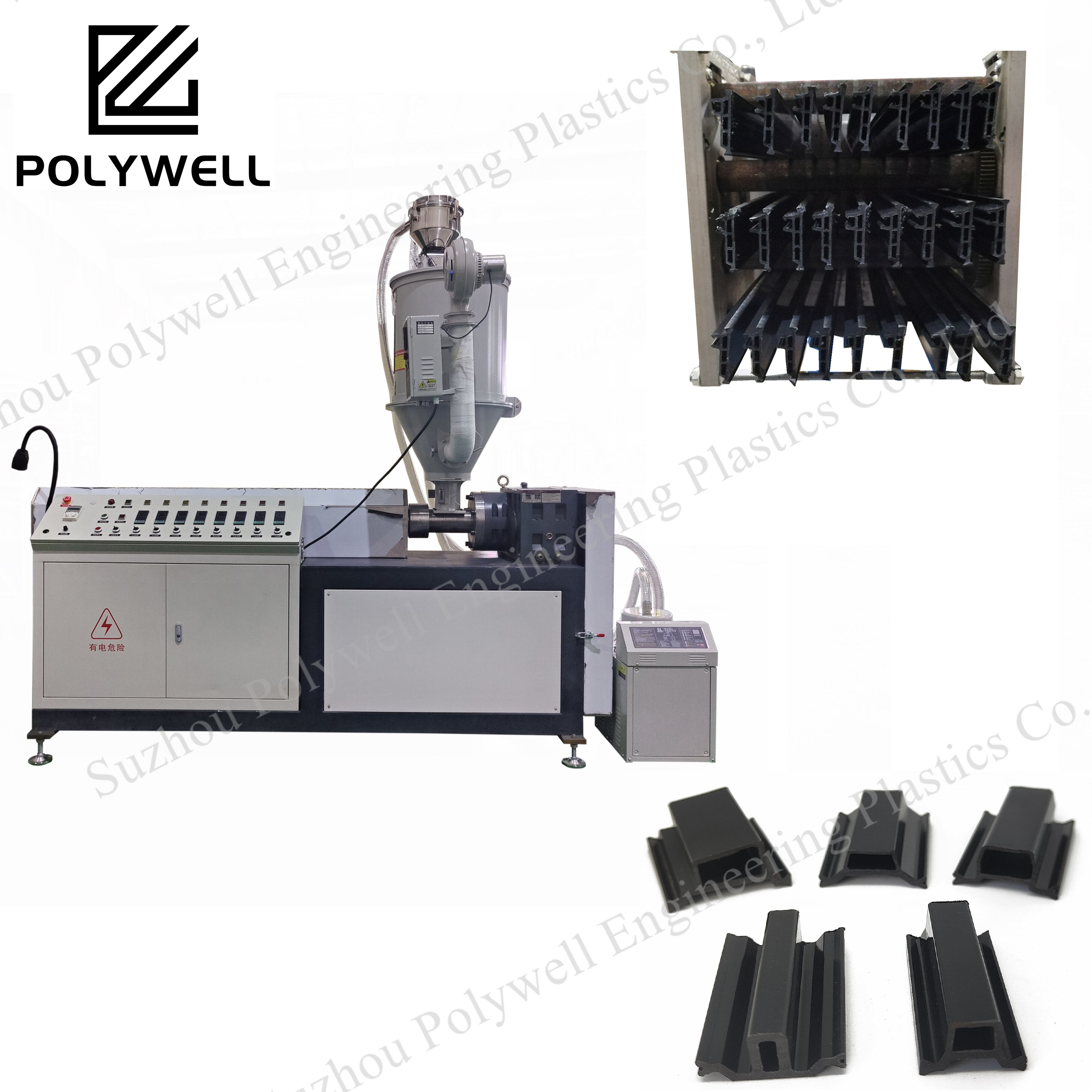

Yas extruder rau polyamide strips, tseem hu ua cov tshuab tsim rau thermal so strips, yog cov cuab yeej tseem ceeb hauv kev tsim khoom lag luam. Cov tshuab no, tshwj xeeb tshaj yog cov ntsia hlau extruder, ua lub luag haujlwm tseem ceeb hauv cov txheej txheem ntawm cov yas extrusion. Los ntawm kev siv cua sov thiab siab, lawv hloov cov ntaub ntawv nyoos polyamide rau hauv cov khoom zoo uas tau siv dav hauv ntau daim ntawv thov.

Lub ntsiab lus tseem ceeb rau qhov tseem ceeb ntawm no yog kev siv ntau yam thiab kev ua haujlwm ntawm cov tshuab yas extrusion. Cov cav tov no yog tsim los tswj cov txheej txheem extrusion nrog precision thiab sib xws, kom ntseeg tau tias cov khoom zoo li qub thiab ruaj khov polyamide strips. Nrog lawv cov thev naus laus zis siab thiab kev ua tau zoo, lawv ua kom cov tuam txhab ua kom tau raws li qhov xav tau ntawm thermal so strips hauv kev tsim kho, tsheb, thiab lwm yam lag luam.

Plastic extruder ua dab tsi?

Plastics extrusion yog ib txwm ntim ntim ntau lawm txheej txheem uas cov khoom siv polymer, enriched nrog rau qhov xav tau additives, yog melted thiab tsim nyob rau hauv ib tug tas mus li txheej txheem. Cov khoom siv raw (polymer) nyob rau hauv daim ntawv ntawm granulates, yog nqus mus rau hauv lub hopper thiab los ntawm lub caj pas pub, tee rau ntawm ib tug rotating ntsia hlau.

Dab tsi yog kev ua haujlwm ntawm PA yas profile extrusion tshuab?

Los tsim cov polyamide thermal break profiles. Cov polyamide thermal break strips kuj paub tias yog cov profiles insulation kub.

Dab tsi yog cov khoom siv raw ntawm PA yas profile extrusion tshuab?

Polyamide 6.6 granules txhawb los ntawm 25% iav fiber ntau.

Dab tsi yog suav nrog PA yas profile ntau lawm kab?

1. PA strips extrusion tshuab nrog tsis siv neeg pub tshuab thiab hopper tshuab ziab khaub ncaws

2. PA yas pwm thiab tuag

3. Txiav tshuab

4. Worktable los yog winder

Polyamide thermal so profiles yog dab tsi?

Polyamide yog siv tau ntau tshaj 30-50 xyoo los tsim cov strips uas ua haujlwm raws li thermal breaks. Qhov no yog vim polyamide muaj thermal conductivity qis. Qhov no pab polyamide txo qhov kev hloov pauv ntawm kub thiab txias los ntawm cov phab ntsa curtain. Cov polyamide strips kuj tuaj yeem coated nrog hmoov lossis anodized. Tag nrho cov no yuav ntxiv kom paub tseeb tias cov curtainwalls haum txawm tias yuav tiv thaiv huab cua nyuaj, uas suav nrog cov cyclones muaj zog, UV rays puas, kev corrosion niaj hnub, thiab ntau ntxiv.

Lub hom phiaj ntawm extrusion tshuab yog dab tsi?

Extrusion yog ib qho txheej txheem uas molten polymer raug yuam los ntawm kev tuag thiab yog siv los tsim cov khoom ntawm ib qho chaw ruaj khov xws li polyamide thermal so profiles.

Tshuab yam ntxwv:

1. Lub thoob yog rhuab los ntawm stainless hlau rhaub, withstand voltage 400V

2. Lub tshuab ziab khaub ncaws ua rau cov khoom siv raw convection nrog cua kub uniformly, thiab ziab uniformity yog zoo. Nws cov txheej txheem thermal rwb thaiv tsev tiv thaiv cov cua sov dissipation thiab txhawb kev txuag hluav taws xob.

3. Cov ntsia hlau tshiab tshwj xeeb kom paub tseeb tias lub tshuab muaj kev siv hluav taws xob tsawg, muaj peev xwm zoo plasticizing thiab ruaj khov extrusion ntws.

4. Lub extruder siv cov khoom zoo carbide twin-screws los xyuas kom meej cov yas siab ntawm PA66GF25 granules

5. Ib cheeb tsam tswj qhov kub thiab txias tswj tau los ntawm ib lub rooj, thiab qhov kub thiab txias tuaj yeem tswj tau ntawm ± 1 ℃.

FAQ

Q: Koj tus MOQ rau polyamide strip extrusion tshuab yog dab tsi?

A: 1 set.

Q: Raws li tus neeg ua si tshiab ntawm polyamide strips extrusion, peb kawm siv lub tshuab li cas?

A: Polywell yuav muab cov ntaub ntawv thiab cov yeeb yaj kiab los pab cov neeg siv khoom siv lub tshuab. Yog tias cov neeg siv khoom xav tau, peb kuj tuaj yeem muab kev pabcuam hauv chaw cob qhia.

Q: Peb puas tuaj yeem kho thiab yuav cov khoom siv raw thiab pwm?

A: Peb tuaj yeem muab txhua yam khoom lag luam ntsig txog polyamide thermal so profiles ntau lawm. Xws li cov khoom siv raw, pwm, lub tshuab txiav, lub rooj ua haujlwm, lub tshuab winder thiab lwm yam.

Q: Lub warranty rau koj lub tshuab yog dab tsi?

A: Rau lub tshuab extruder, nws yog ib xyoos. Peb muaj kev ntseeg siab rau peb cov khoom, thiab ntim lawv zoo ua ntej xa khoom, yog li feem ntau koj yuav tau txais koj qhov kev txiav txim zoo. Txhua qhov teeb meem zoo, peb yuav daws nws tam sim ntawd.

Q: Koj cov nqe lus them nqi yog dab tsi?

A: 50% T / T tso nyiaj ua ntej ntau lawm, 50% T / T tshuav nyiaj li cas ua ntej thauj khoom.

Peb qhov kev pabcuam

Ib tug rau ib qho kev pab tswv yim.

Cov kws tshaj lij engineers los tham txog cov ntaub ntawv kev, tsim duab kos duab.

Zoo meej kev thauj mus los ntawm hiav txwv lossis huab cua.

Kev pab cuam tom qab muag txawv teb chaws.

Pab pawg kws tshaj lij engineers.

Zoo siab txais tos tuaj xyuas lub Hoobkas txhua lub sijhawm.

Ntau lawm Ceev |

Nyob ib ncig ntawm 8-14 cm / min |

Sawb Shape |

Txhua yam zoo li |

Raw Khoom |

PA6.6 granules reinforced los ntawm 25% fiber iav |

Txias |

Dej Txias |

Kev siv |

Ua thermal so strip |

Hom |

Yas extrusion tshuab |

Tshuab winding |

Muaj |

Txiav tshuab |

Muaj |

Lub rooj ua haujlwm |

Muaj |

PA66GF25 Polyamide Profiles Extrusion M tshuab Kuv suav nrog:

Xaiv Polywell txhais tau hais tias xaiv qhov tseeb ntawm tus khub txhim khu kev qha, tuaj yeem pab pawg thiab muab kev txhawb nqa txhua hnub. Peb nyob qhov twg koj xav tau peb, thaum twg koj xav tau peb.

EN

EN