PA66 Lub Nplej 25% Lub Cav Roj Reformed Raw Vajtshuab rau Heat Insulation Strip Nylon Extrusion Profile PA Chain Guide

Chav Kawm Ntawv Vajtse Nylon Chav Kawm Ntawv Vajtse Vajtse Chav Kawm Ntawv Vajtse

- Saib xyuas

- Cov khoom pom zoo

- Piv txwv dej cov ntsiab lus tsawg dua 0.2% los ntawm qhov hnyav.

- Kev kuaj mob: (23 ± 2) ºC thiab (50 ± 10)% txheeb ze av noo.

- Cov lus qhia tshwj xeeb uas cim "a" tsuas yog siv rau I-shaped strip txwv tsis pub, cov ntsiab lus xaus ntawm tus neeg muag khoom thiab tus neeg yuav khoom los ntawm kev sib tham, yuav tsum tau sau rau hauv daim ntawv cog lus lossis kev yuav khoom.

Khoom piav qhia:

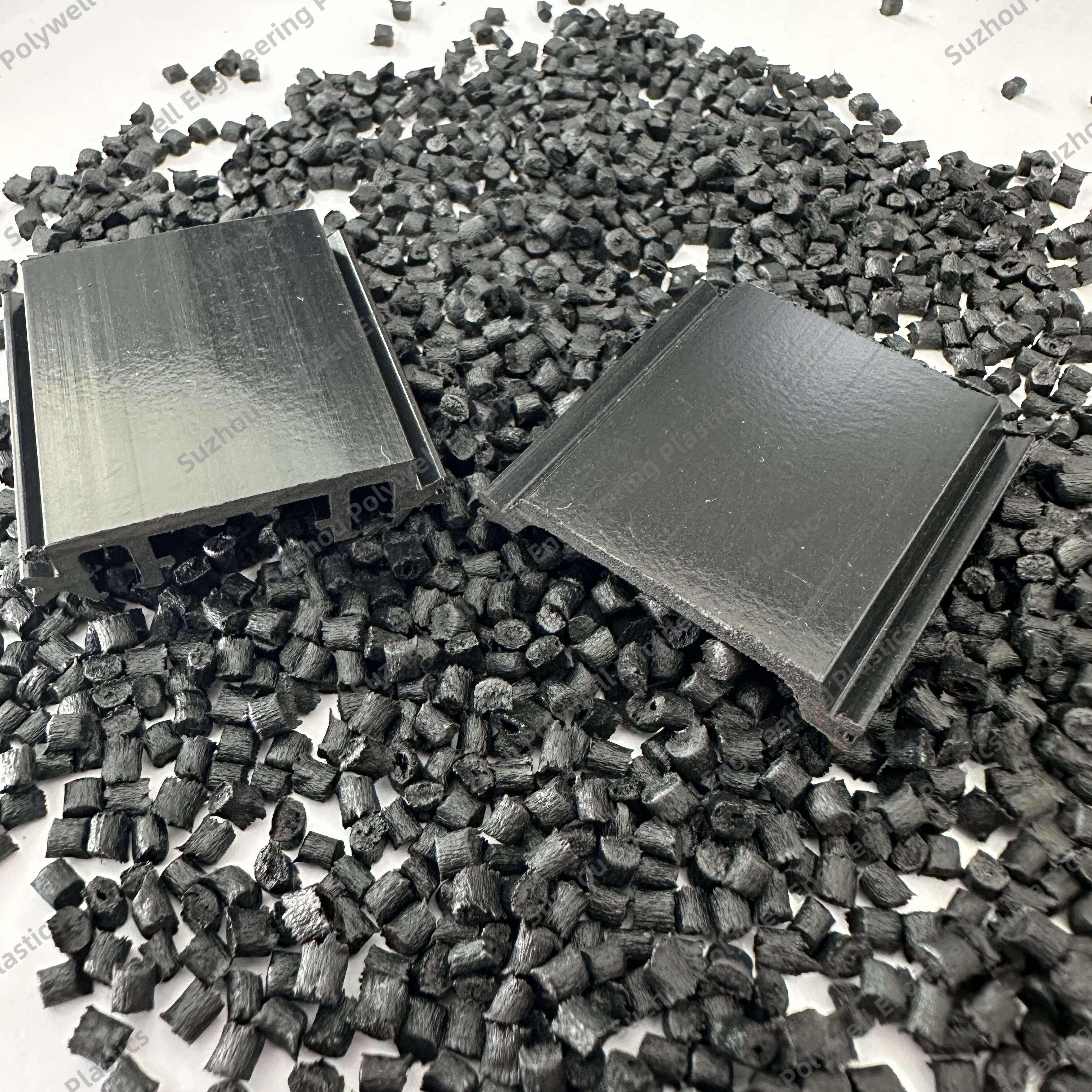

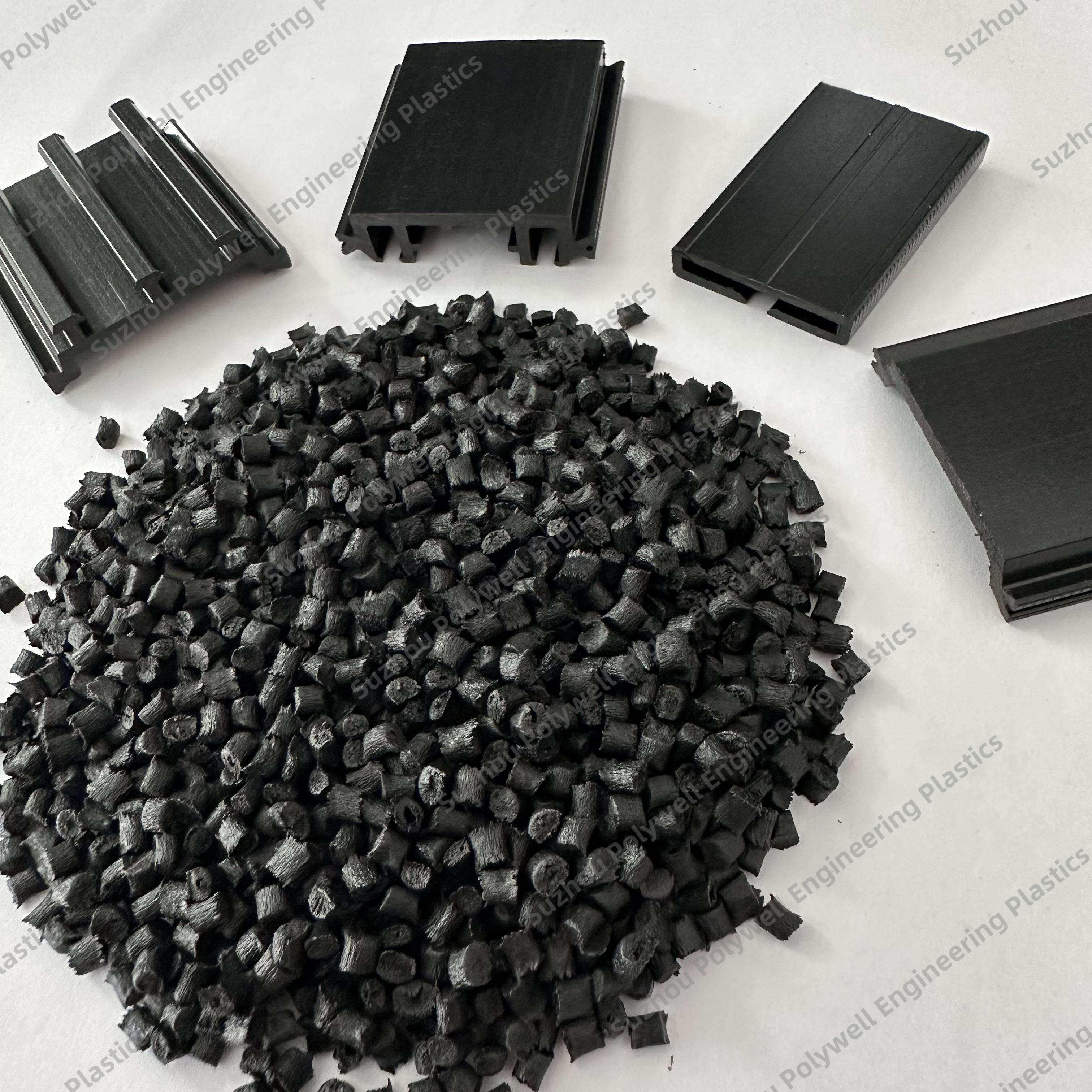

Glass fiber reinforced PA 6.6 granules nrog heat aging resistance extrusion moulding grade. Nws yog cov khoom raw zoo rau thermal break profiles ntawm high stiffness thiab dimensional stability.

PA66GF25 granules raug fiberglass los ntawm kev ua kom ntau dua. Qhov xwm txheej ntawm cov khoom ua tiav los ntawm cov khoom siv no tuaj yeem txiav txim siab rau lub standard kaw lus.

PA66GF25 cov rojntawm tuav hauv PA66 resin. Tom qab ntawd cov rojntawm yog tsim los ntawm cov nta npliag nrog cov nta npliag fiberglass, cov kho vaj tswv tau zoo thiab lwm yam khoom ntxur nrog.

PA66 GF25 yog 25% iav fiber reinforced PA 66. Nws ua kom pom cov khoom zoo xws li lub zog siab dua, rigidity, creep zog thiab qhov ntev stability.

Qhov zoo:

1. Peb yog ib lub tuam txhab lag luam nrog peb lub hoobkas

Peb yog cov chaw tsim khoom tshaj lij ntawm cov khoom tshwj xeeb rau polyamide thermal break profiles nrog ntau tshaj 10 xyoo kev paub.

2. Kev pabcuam zoo & Cov khoom zoo tshaj plaws

Cov cuab yeej zoo tshaj plaws, muaj peev xwm & muaj kev paub tsim qauv thiab cov neeg ua haujlwm muaj peev xwm, kev tswj hwm kev tsim khoom siab thiab cov qauv tswj hwm zoo nruj.

3. Tswj zoo

Cov txheej txheem raug tshuaj xyuas thiab tswj ua ntej ntim cov khoom. Peb xyuas kom meej tias txhua qhov khoom xa tuaj yog qhov zoo.

4. Customized Service

1. Mus yoo rau koj xov lwm nws, kuv tias cov tsis txais lawv dawb ntawm kuv mus yuav tsum kuv yeej hmoov qhia li cas li cas los yuav tsum kuv muaj kev pab nrog kuv tus neeg!

Hais txog xim:

Cov xim ntawm peb PA66GF25 granules yog dub, tab sis peb kuj tuaj yeem kho raws li cov neeg siv khoom xav tau.

Daim ntawv thov:

Lub PA66 granules nrog fiber ntau iav yog tsuas yog siv nyob rau hauv thermal so strips, uas yog siv nyob rau hauv txhuas qhov rais thiab qhov rooj. Peb cov granules muaj zoo fluidity yog li lav koj cov khoom du. Cov khoom siv raw zoo tuaj yeem txo tus nqi ntawm kev tsis lees paub, thiab tuaj yeem tsim cov strips zoo.

Package thiab Delivery:

Ntim cov ntsiab lus |

25 kg / hnab |

Lub sijhawm ua haujlwm |

10-15 hnub ua haujlwm |

Cov ntaub ntawv xa tuaj |

10-16 tons ib 20 feet thawv 20-25 tons p er 40ft thawv |

FAQ:

Q: Txog Qauv

A: Qauv yog dawb, tab sis tus nqi xa khoom yog sau. Cov neeg siv khoom kuj tuaj yeem xaiv lawv tus kheej koom tes courier tuam txhab.

Q: Txog MOQ

A: Rau polyamide granules, MOQ yog 1 tuj. Rau cov thermal so strips, MOQ yog 5,000 meters.

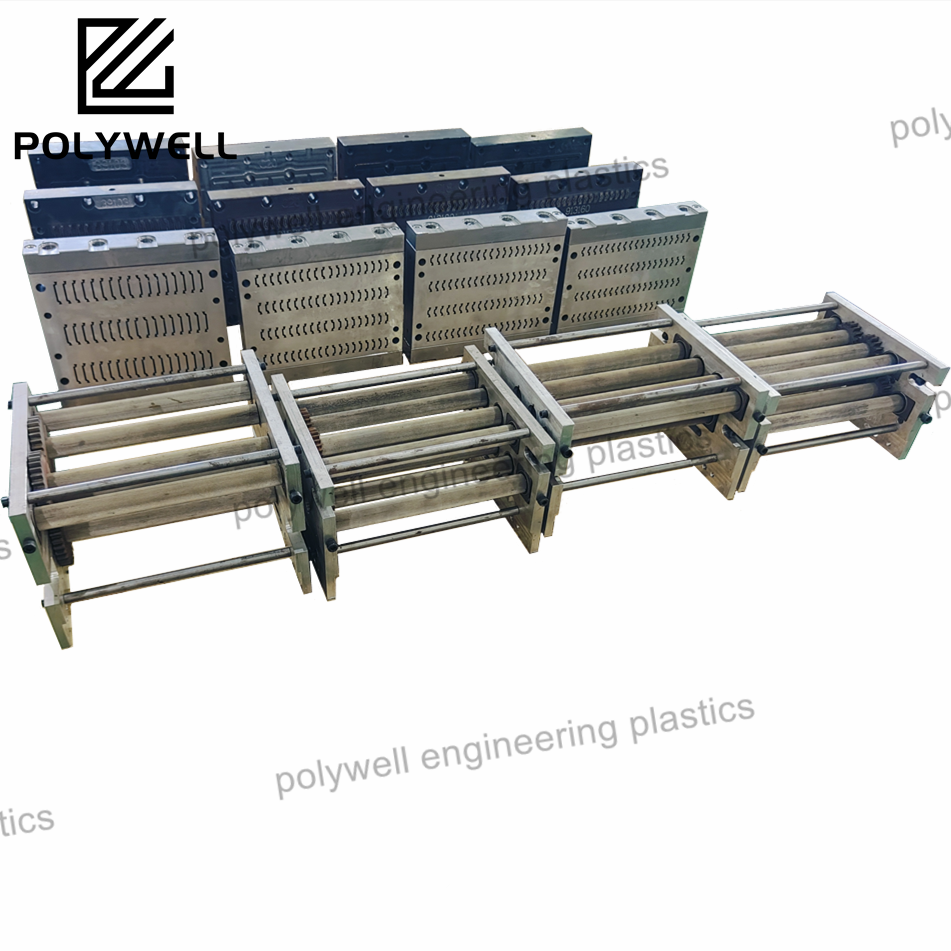

Q: Txog Customizing Tshwj Xeeb Zoo Ntawm Polyamide Profiles Thiab Nws Lub Sij Hawm

A: Koj tuaj yeem kho cov duab tshwj xeeb ntawm polyamide strips. Yog tias peb tsis ua raws li cov qauv no ua ntej, peb yuav ua pwm tshiab rau koj, thiab cov neeg siv khoom xav tau them nyiaj rau pwm.

Q: Txog Customizing Package Style thiab Marks

A: Koj tuaj yeem kho lub pob style thiab cov cim.

Q: Vim li cas koj tus nqi siab dua / qis dua lwm tus?

A: Rau xyoo specializing hauv polyamide granules thiab thermal break strips tau muab rau peb cov neeg ua haujlwm muaj kev paub thiab muaj peev xwm thiab cov neeg ua haujlwm tsim khoom. Peb cog lus txog kev ruaj ntseg ntawm cov khoom thiab qhov zoo ntawm cov khoom raw. Tsis tas li, peb tuaj yeem muab kev txhawb nqa thev naus laus zis los ntawm cov khoom raw mus rau cov khoom siv kawg.

Q: Hais txog warranty

A: 1 xyoos. Peb muaj kev ntseeg siab rau peb cov khoom, thiab ntim lawv zoo ua ntej xa khoom, yog li feem ntau koj yuav tau txais koj qhov kev txiav txim zoo. Txhua qhov teeb meem zoo, peb yuav daws nws tam sim ntawd.

Q: Txog Kev Them Nyiaj lossis lwm yam lus nug

A: 50% T / T tso nyiaj ua ntej ntau lawm, 50% T / T tshuav nyiaj li cas ua ntej thauj khoom.

Product Performance

Khoom |

Chav tsev |

GB/T 23615.1-2009 |

PW-Technical specification |

Qhov ntom |

g/cm3 |

1.3±0.05 |

1.28-1.35 |

Linear expansion coefficient |

K-1 |

(2.3-3.5)×10-5 |

(2.3-3.5)×10-5 |

Vicat softening kub |

ºC |

≥230 |

≥233 |

Melting point |

ºC |

≥240 |

≥240 |

Kev ntsuas tensile tawg |

- |

Tsis muaj kab nrib pleb |

Tsis muaj kab nrib pleb |

Ntug hardness |

- |

80±5 |

77-85 |

Kev cuam tshuam lub zog (tsis suav nrog) |

KJ/m2 |

≥35 |

≥38 |

Tensile zog (longitudinal) |

MPa |

≥80ib |

≥82ib |

Elasticity modulus |

MPa |

≥4500 |

≥4550 |

Elongation thaum so |

% |

≥2.5 |

≥2.6 |

Tensile zog (transverse) |

MPa |

≥70ib |

≥70ib |

High kub tensile zog (transverse) |

MPa |

≥45ib |

≥47ib |

Tsawg kub tensile zog (transverse) |

MPa |

≥80ib |

≥81ib |

Dej tsis kam tensile zog (transverse) |

MPa |

≥35ib |

≥35ib |

Kev laus kuj tensile zog (transverse) |

MPa |

≥50ib |

≥50ib |

EN

EN