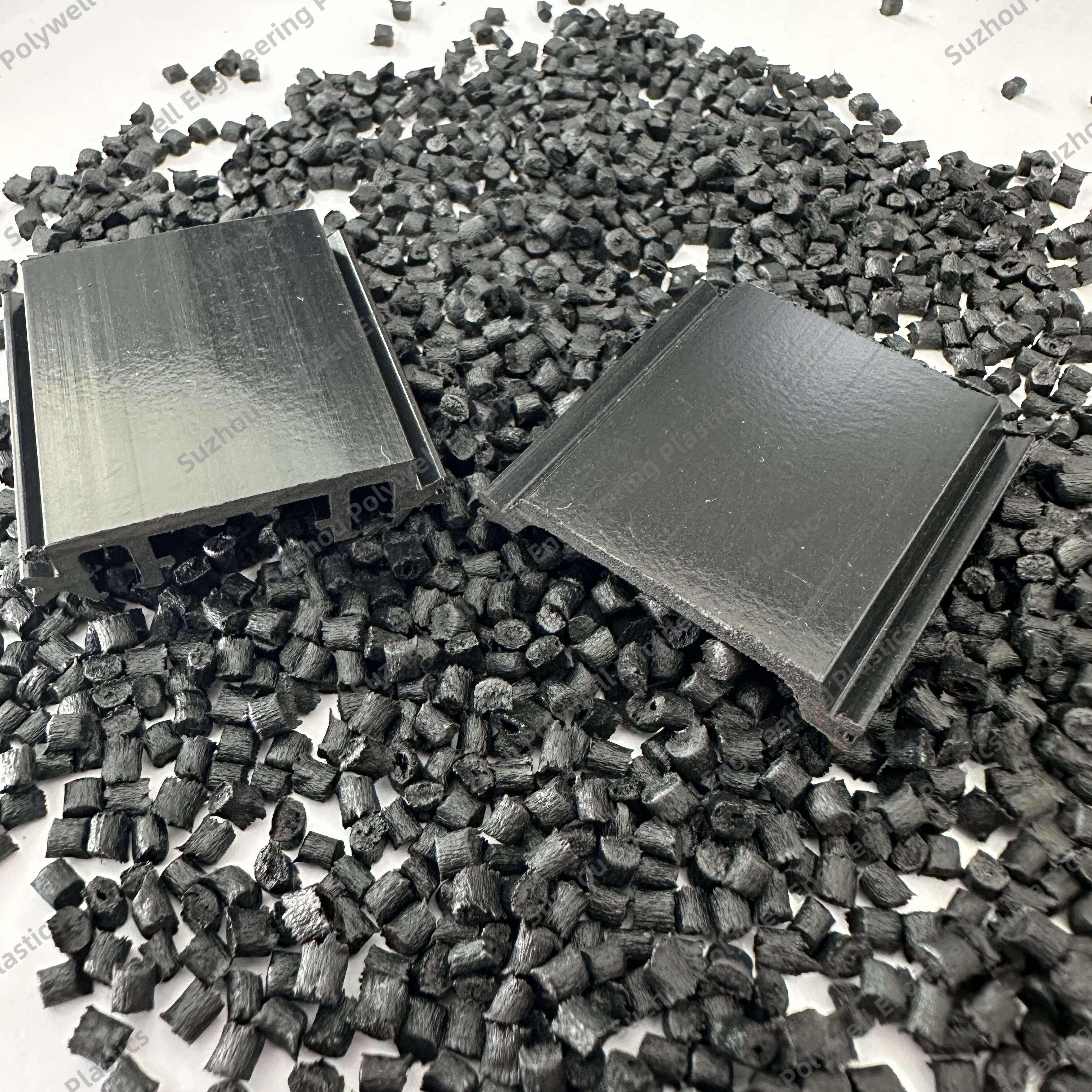

Nylon Raw Khoom Extrusion Qib Yas Polyamide Granule Rau Thaum tshav kub kub rwb thaiv tsev sawb ntau lawm khoom

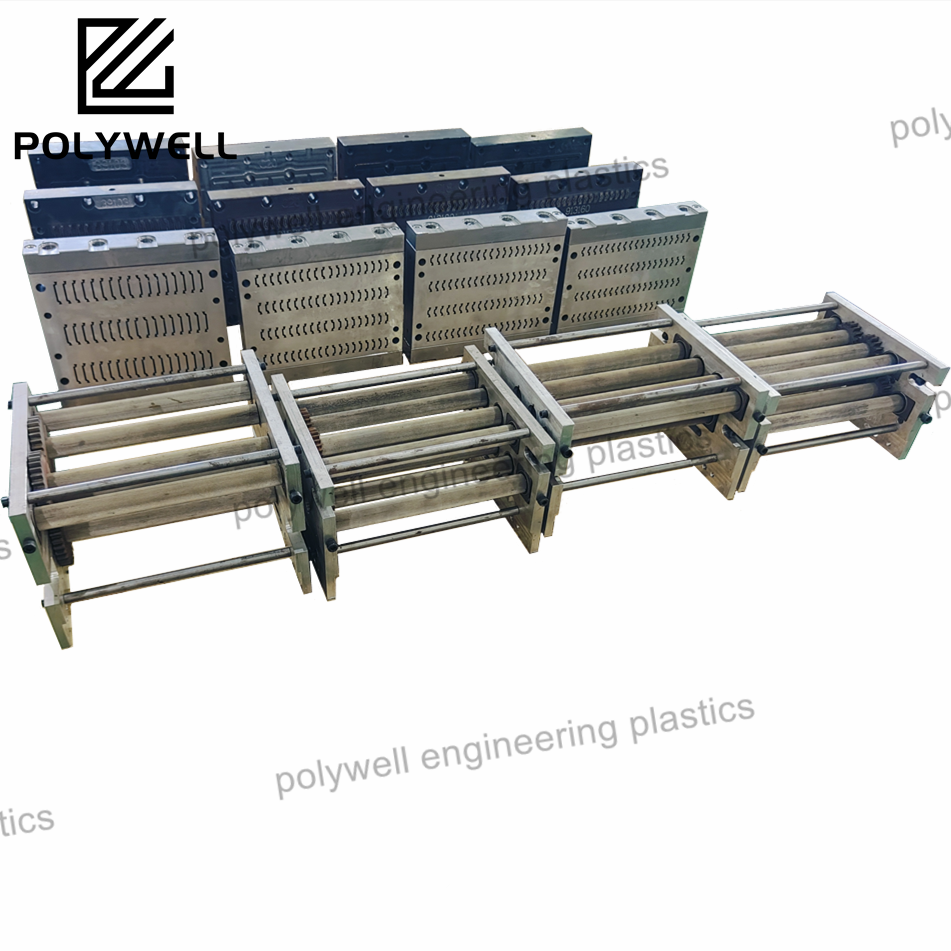

Vaj Huam Lub Tshuab, Nylon Rail Guide Vaj Huam, Ntawv Tshuab Rau Qhov Kev Ntawv

- Saib xyuas

- Cov khoom pom zoo

- Piv txwv dej cov ntsiab lus tsawg dua 0.2% los ntawm qhov hnyav.

- Cov kev sib txuas ntawm lub tsev kawm: (23±2)ºC thiab (50±10)% qhov chaw nyob rau hauv qhov chaw nyob.

- Cov cim tshwj xeeb uas muaj "a" tsuas yog rau cov ntaub tshwj xeeb rau lub tshoos I; thaum ib qho, cov cim tshwj xeeb uas cov thawj tswv thiab cov kws kho tswv tau txhawb tshwj xeeb yuav tsum sau rau hauv cov lus qhia los ntawm cov thawj tswv thiab cov kws kho tswv lossis rau hauv cov lus qhia los ntawm cov thawj tswv thiab cov kws kho tswv.

Qhov zoo:

1. Peb yog cov kws tsim khoom los ntawm kev tsim khoom tshwj xeeb rau hauv qhov cua txias ntawm polyamide uas muaj ntau dua 15 xyoo ntawm kev ua haujlwm.

2. Kev pabcuam zoo & Cov khoom zoo tshaj plaws

Cov khoom siv zoo tshaj plaws, cov neeg design uas paub thiab muaj kev ua haujlwm, cov neeg ua haujlwm uas paub thiab muaj kev ua haujlwm, kev paub ua haujlwm ntawm kev xaiv khoom siv, thiab kev paub ua haujlwm ntawm kev ntsuas qhov zoo.

3. Tswj zoo

Cov txheej txheem raug kuaj thiab tswj hwm ua ntej packing cov khoom. Peb ntseeg tau tias txhua daim khoom xa tuaj yog qhov zoo.

4. Customized Service

Yog tias koj daim ntawv thov xav tau qee yam tshwj xeeb, peb yuav ua haujlwm nrog koj los tsim cov qauv tsim tshwj xeeb los pab koj tsim cov khoom uas yuav ua rau koj cov neeg siv khoom txaus siab.

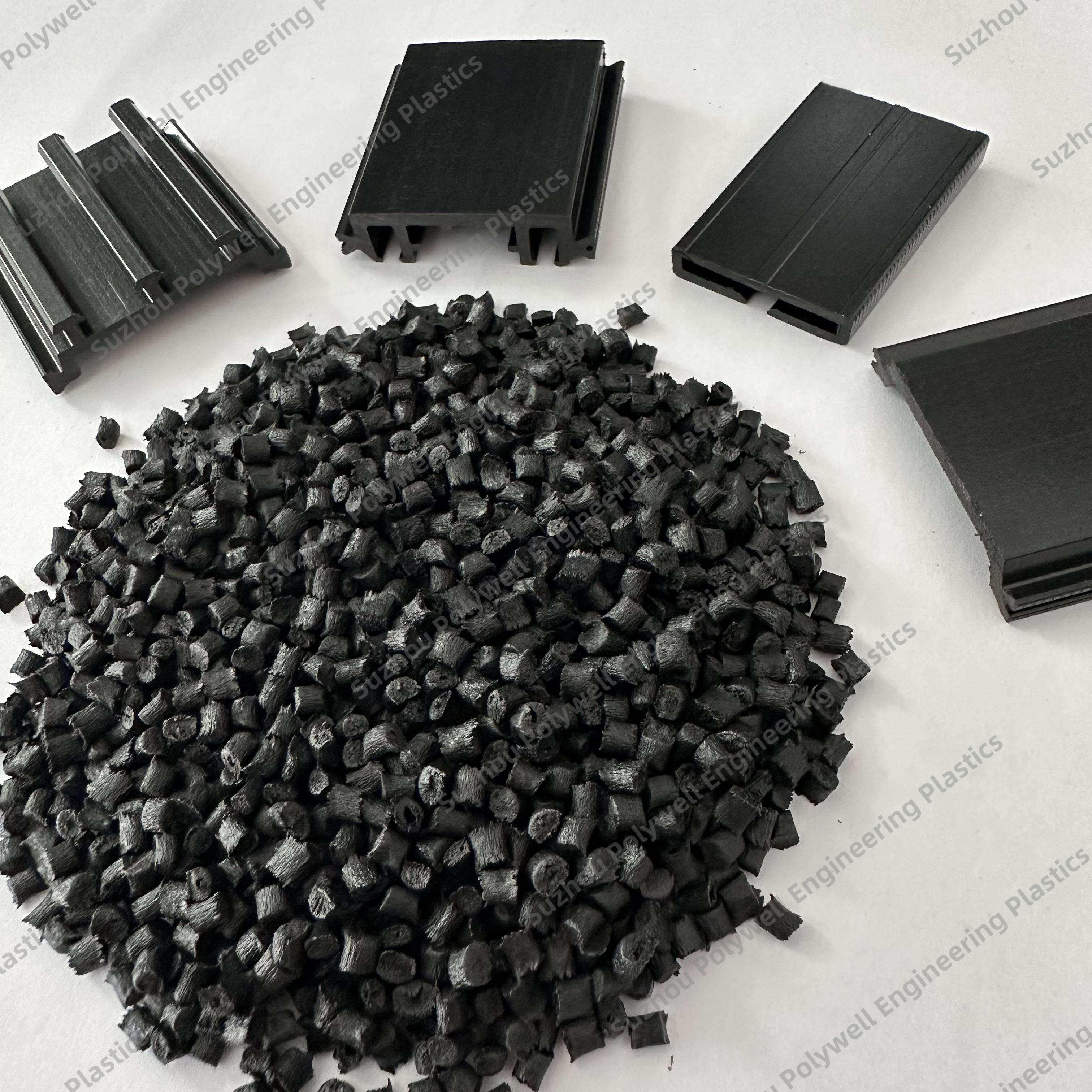

Khoom piav qhia:

PA 6.6 granules uas muaj lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim nt......

PA66GF25 granules raug fiberglass los ntawm kev ua kom ntau dua. Qhov xwm txheej ntawm cov khoom ua tiav los ntawm cov khoom siv no tuaj yeem txiav txim siab rau lub standard kaw lus.

TPA66GF25 granules yog los ntawm PA66 resin. Tom qab ntawd, cov granules yog tsim los ntawm lub tshuab ntsuas ob lub tshuab ntsuas tom qab ua cov tshuab ntsuas, cov tshuab ntsuas uas muaj kev ntsuas zoo, thiab cov tshuab ntsuas ntau yam.

Dab tsi yog GF hauv cov khoom siv yas?

Nylon uas muaj lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim ntawm lub tswv yim......

PA66 nta

1. Nws muaj kev ua haujlwm zoo heev, qhov siab ntawm kev nyuaj thiab qhov siab ntawm kev txaus siab.

2. Lub ntsuab dej muaj kev zoo huv thiab tuaj yeem txiav txim siab cov lus nug sib txawv ntawm kev huen siab.

3. Tus nqi shrinkage ntawm PA66 yog nyob nruab nrab ntawm 1% thiab 2%. Qhov sib ntxiv ntawm cov iav fiber ntau ntxiv tuaj yeem txo qis qis rau 0.2% ~ 1%. Lub shrinkage piv yog loj nyob rau hauv cov kev taw qhia ntws thiab nyob rau hauv cov kev taw qhia perpendicular mus rau lub ntws kev taw qhia.

4. PA66 tiv taus ntau cov kuab tshuaj tab sis tsis tshua muaj resistant rau acids thiab lwm yam tshuaj chlorinating.

5. Los ntawm qhov ntxiv ntawm cov flame retardants sib txawv, PA66 tuaj yeem tau qhov effect ntawm kev tswb qhov cua sib txawv.

Hais txog xim:

Cov xim ntawm peb PA66GF25 granules yog dub, tab sis peb kuj tuaj yeem kho raws li cov neeg siv khoom xav tau.

Daim ntawv thov:

Cov paus PA66 uas muaj fiberglass yog siv rau hauv cov khoom tso cua tsaus rau qhov kawg, uas siv rau hauv cov lwm thiab qhov tawg los ntawm aluminum. Cov paus ntawm peb muaj kev tswj hwm zoo, thiab nws pab rau koj siv tau raws li qhov yuav tau. Cov ntaub sib thooj zoo tuaj yeem txo qhov ntau ntawm cov khoom uas tsis zoo thiab tuaj yeem tsim cov khoom tso cua tsaus zoo heev.

Package thiab Delivery:

Ntim cov ntsiab lus |

25 kg / hnab |

Lub sijhawm ua haujlwm |

10-15 hnub ua haujlwm |

Cov ntaub ntawv xa tuaj |

10-16 tus per 20-foot container 20-25 tons per 40-foot container r |

Product Performance

Khoom |

Chav tsev |

GB/T 23615.1-2009 |

PW-Technical specification |

Qhov ntom |

g/cm³ |

1.3±0.05 |

1.28-1.35 |

Linear expansion coefficient |

K-1 |

(2.3-3.5)×10⁻⁵ |

(2.3-3.5)×10⁻⁵ |

Vicat softening kub |

ºC |

≥230 |

≥233 |

Melting point |

ºC |

≥240 |

≥240 |

Kev ntsuas tensile tawg |

- |

Tsis muaj kab nrib pleb |

Tsis muaj kab nrib pleb |

Ntug hardness |

- |

80±5 |

77-85 |

Impact zog (Tsis muaj) |

KJ/m² |

≥35 |

≥38 |

Tensile zog (longitudinal) |

MPa |

≥80ib |

≥82ib |

Elasticity modulus |

MPa |

≥4500 |

≥4550 |

Elongation thaum so |

% |

≥2.5 |

≥2.6 |

Tensile zog (transverse) |

MPa |

≥70ib |

≥70ib |

High kub tensile zog (transverse) |

MPa |

≥45ib |

≥47ib |

Tsawg kub tensile zog (transverse) |

MPa |

≥80ib |

≥81ib |

Water resistance tensile zog (transverse) |

MPa |

≥35ib |

≥35ib |

Aging resistance tensile zog (transverse) |

MPa |

≥50ib |

≥50ib |

FAQ:

Q: Txog Qauv

Q: Ntawv sample lawv thiaj, ntawm lub yim express fee yog ua si. Rau li, koom nyob rau hauv tus kompaq koj xav kom paub.

Q: Txog MOQ

A: Rau polyamide granules, MOQ yog 1 tuj. Rau cov thermal so strips, MOQ yog 5,000 meters.

Q: Txog Customizing Tshwj Xeeb Zoo Ntawm Polyamide Profiles Thiab Nws Lub Sij Hawm

A: Koj tuaj yeem kho cov duab tshwj xeeb ntawm polyamide strips. Yog tias peb tsis ua raws li cov qauv no ua ntej, peb yuav ua pwm tshiab rau koj, thiab cov neeg siv khoom xav tau them nyiaj rau pwm.

Q: Txog Customizing Package Style thiab Marks

A: Koj tuaj yeem kho lub pob style thiab cov cim.

Q: Vim li cas koj tus nqi siab dua / qis dua lwm tus?

A: Rau xyoo ntev uas tshuaj xyoo ntawm cov paus polyamide thiab cov paus ntaus rau hauv qhov cua ntsuas tau pab rau peb muaj cov neeg sib tham thiab cov neeg tsim khoom uas muaj kev paub zoo thiab muaj kev paub txog kev tsim khoom. Peb xav tias cov khoom yuav tsoo tseg thiab cov khoom siv yuav zoo. Ntawd li, peb tuaj yeem pab koj thaum koj yuav cov khoom siv los ntawm qhov kawg mus rau qhov kawg.

Q: Hais txog warranty

A: 1 xyoo. Peb muaj kev paub zoo rau cov khoom ntawm peb thiab peb ua cov khoom rau hauv qhov chaw nyob ua ntej peb xa tuaj, yog li koj yuav tau txais cov khoom ntawm koj rau hauv qhov chaw nyob. Yog tias muaj qhov teeb meem rau cov khoom, peb yuav tshaj tshuaj rau qhov teeb meem ntawd.

Q: Txog kev nqi lossis cov lus nug lwm yam

A: 50% T / T tso nyiaj ua ntej ntau lawm, 50% T / T tshuav nyiaj li cas ua ntej thauj khoom.

EN

EN