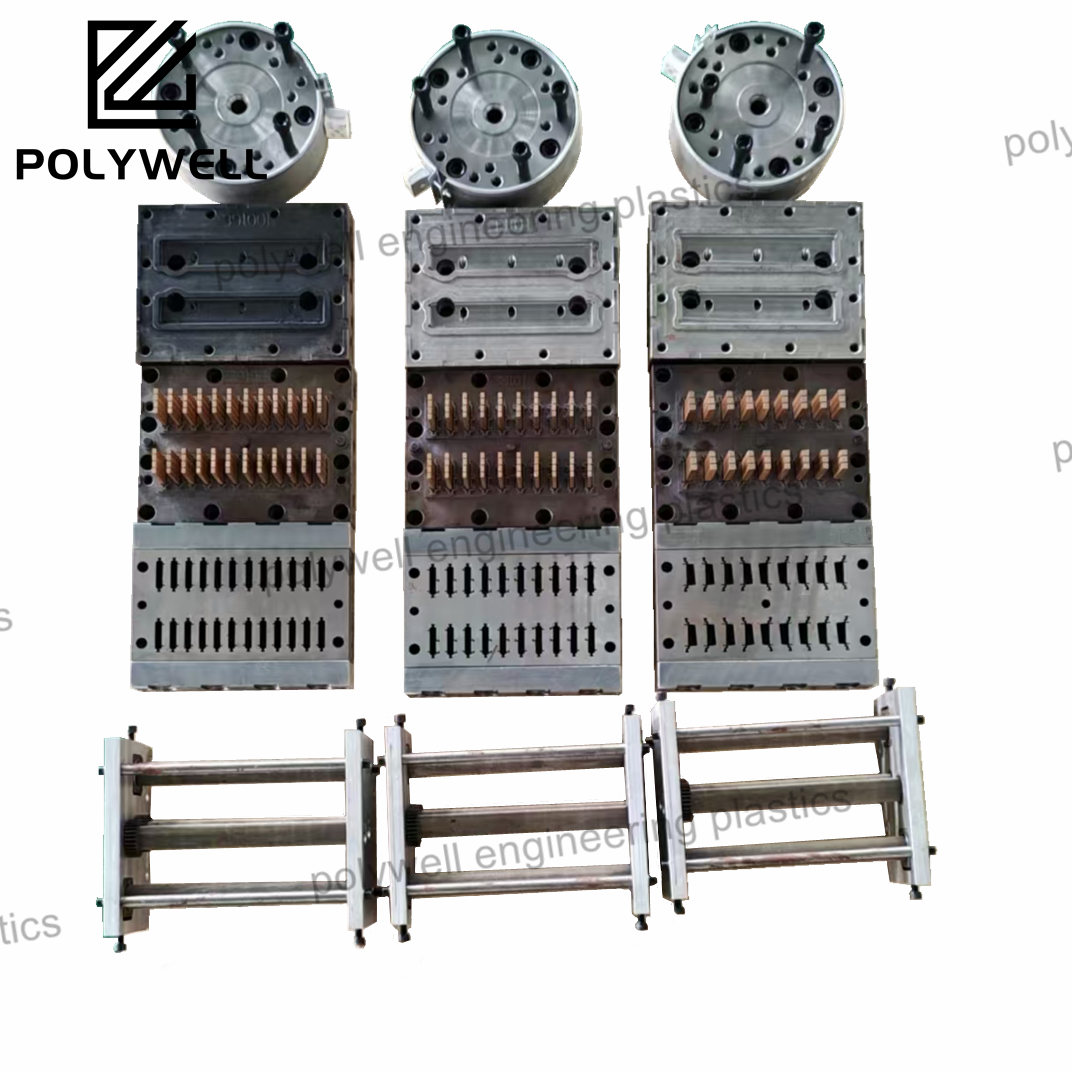

Qhov ceev npawg plastic yog qhov cuam tshuam, thiab feem ntau yog qhov tseem ceeb tshaj plaws, hauv qhov ceev npawg uas cov khoom siv plastic tau tsim. Nws yog ib qhov chaw tsim los ntawm qhov cub zoo li P20 lossis H13, uas tau raug kho kom meej, siv kaw, thiab txias kom muaj kev sib dhos zoo li kab. Qhov ceev npawg muaj cheeb kheem ntawm kev pib rau lub thawj hom polymer uas muaj zog thiab tso nws mus rau hauv ib qhov kev ncaj ncees uas muaj daim duab pla xwm ob teb. Lub ntev ntawm qhov ceev npawg, lossis lub manifold, tau raug tsim los ntawm kev siv cov lus qhia ntawm kev nyob deb ntawm dej kom tau paub seb cov polymer thawj yuav tuaj txog qhov ceev npawg nrog ib qhov zog thiab siab zoo ib yam rau tag nrho qhov chaw tso. No yog qhov tseem ceeb kom tiv thaiv cov teeb meem xws li qhov thickness tsis zoo lossis "bambooing." Lub ceev npawg kuj tsum xav txog cov kev ua raws li qhov khoom, tshaj tshi die swell—the kev nthuav dav ntawm cov polymer viscoelastic thawj thaum tso tseg los ntawm qhov ceev npawg vim tias qhov siab hauv tawm. Yog li, qhov ceev npawg tsis yog ib qhov tshwj xeeb ntawm qhov profile uas xav tau, tab sis nws yooj yooj me me thiab sib txawv. Rau cov profile nyuaj, qhov ceev npawg yuav raug chia ua ntau qhov plates kom ua kom easier thiab kho kom sai. Qhov kev ua haujlwm ntawm ib qhov ceev npawg plastic yog qhov tseem ceeb rau kev tsim qhov ntev, kev txias, thiab qhov zoo tshaj plaws ntawm qhov profile uas tau ceev npawg, uas tsim qhov kev tsim thiab kho qhov ceev npawg los yog ib qhov chaw tshwj xeeb uas sib xyeeb nrog kev paub txog kev tshawb fawb thiab software simulation.