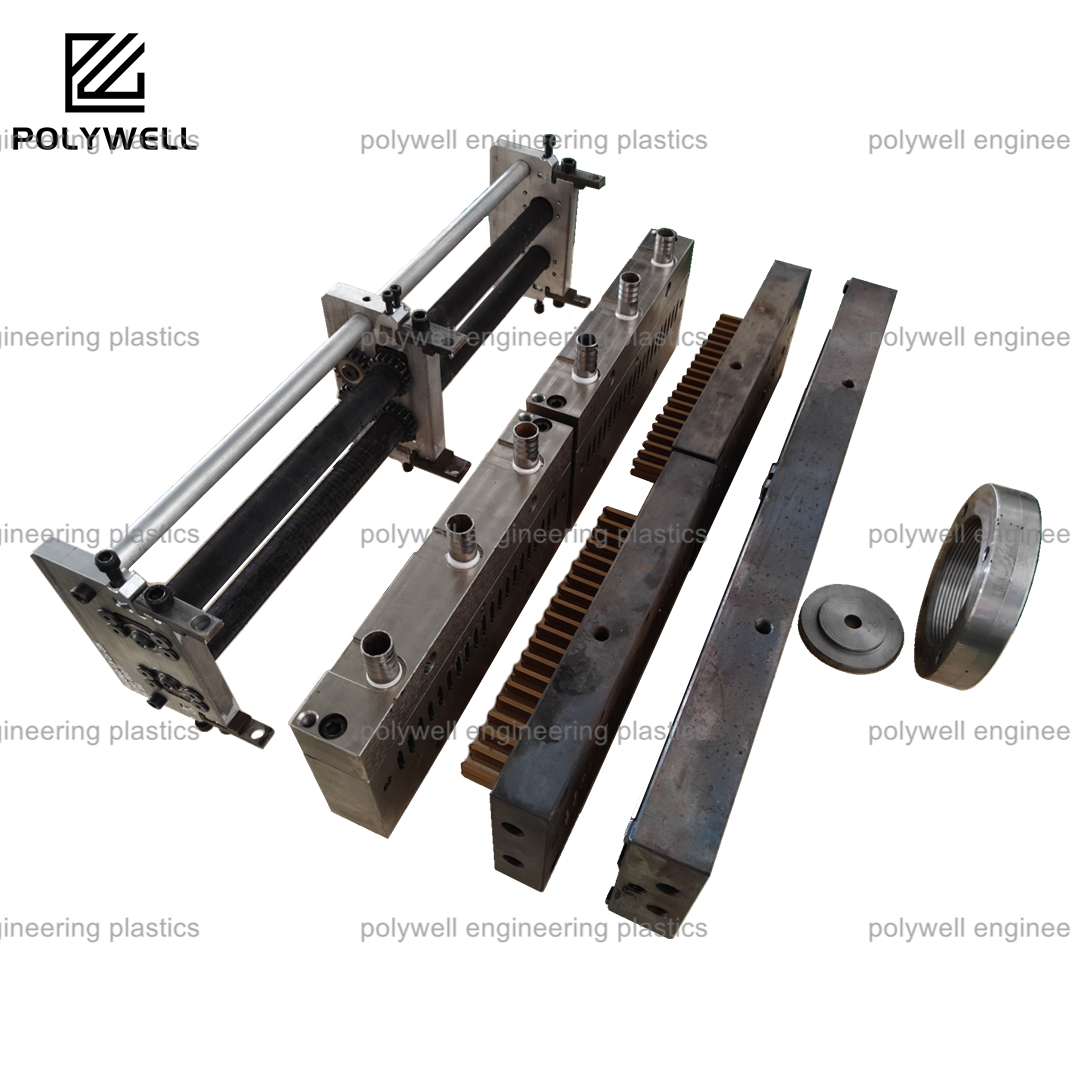

Lub npe "PA extrusion mould" txhais tau tias yog qhov chaw siv rau kev tsim tshuab, tseem ceeb tshaj plaws yog qhov die, siv nyob rau hauv kev tsim tshuab polyamide rau ib qho profile, tube, sheet lossis filament. Qhov chaw no yog ib qhov cuab yeej tseem ceeb uas txheej xwm lub geometry, lub surface quality, thiab lub dimensional accuracy ntawm cov extrudate. Kev tsim thiab sau ua ib qhov die rau polyamide yuav tsum xav ntau ntxiv txog cov khoom siv tshiab thiab kawg ntawm PA. Ib qhov teeb meem tseem ceeb yog kev daws teeb meem ntawm qhov shrinkage uas tuaj yeem zoo li anisotropic thaum PA melt nguam taws thiab solidifies. Lub geometry ntawm die yog tseem tsum muaj kev piav qhia kom raug rau kev kho qhov post-die swelling (die swell) thiab shrinkage tom ntej. Lub flow path hauv die yuav tsum muaj kev pib los tiv thaiv qhov chaw uas khoom tuaj yeem stagnate, degrade, thiab tsim black specks lossis gels hauv khoom lag luam. Lub land length, lub chaw tom ntej ntawm die flow channel, yog tseem ceeb heev rau kev tsim kom muaj stability rau thawj thawj thiab kom muaj kev raug zoo txaus siab. Lub temperature control yog ib qhov tseem ceeb tshaj plaws; lub die feem ntau muaj ntau qhov independent heating zones thiab, txawm li cas los xij, cooling circuits kom muaj kev raug zoo txaus siab ntawm thermal profile txhua qhov chaw ntawm melt. Lub wear resistance yog ib qhov tseem ceeb dua, tshooj tshuaj thaum tsim khoom siv glass-filled PA grades, uas muaj kev abrasive loj. Yog li, cov extrusion moulds rau PA feem ntau tsim los ntawm high-grade tool steels thiab feem ntau muaj cov wear-resistant coatings lossis hardened inserts hauv qhov chaw tseem ceeb. Lub design yog ib qhov kev sib txig sib to taub hau, fluid dynamics, heat transfer, thiab material science, uas muaj zoo tshaj plaws rau kev tsim ib qhov kev tsim kho mob thiab ib qhov khoom lag luam zoo, muaj kev raug zoo txaus siab.