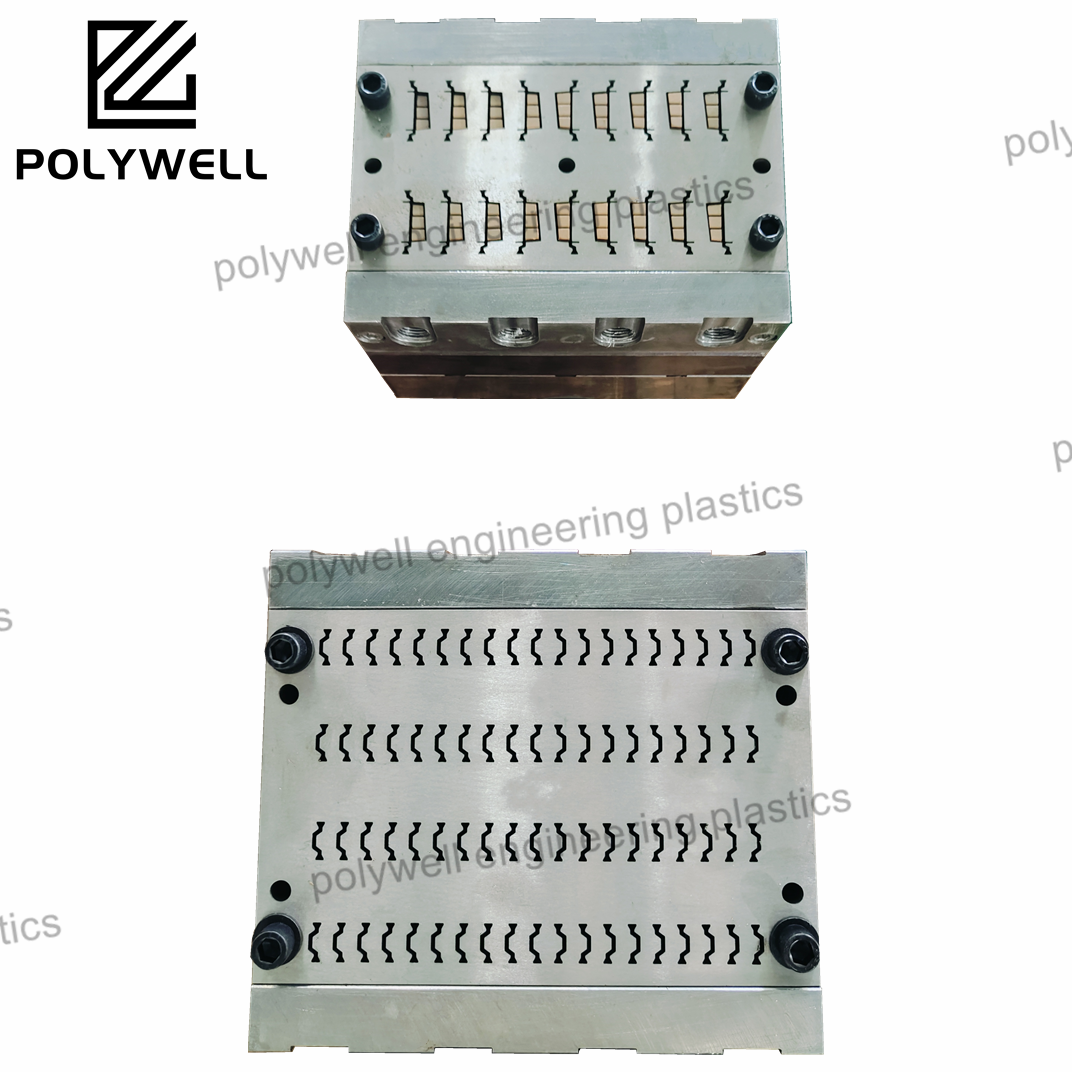

Kev tsim kho tshuab ntxig, uas feem ntau hu ua kev tsim kho tshuab ntxig, yog qhov chaw nyob ze ntawm kev tsim khoom siv duab los ntawm khoom siv duab, suav nrog kev tsim kho cov tshuab ntxig zoo uas yuav pib tau rau cov khoom siv duab. Qhov kev tsim no muaj qhov pheej hmli (cavity) thiab qhov pheej hlwi (core), qhov rooj kawg (runner systems - cold or hot runners), qhov caij ntxig khoom (gating mechanisms), thiab qhov tshuab ntxig tawm. Cov ntsiab lus tseem ceeb tau suav nrog kev xaiv cov khoom siv rau tshuab ntxig xws li cov neeg tsim tshuab (xws li D2 lossis S7) kom zoo siab thiab tsis hlo tawg, thiab sau cov rooj kawg kom tuaj yeem coj tsis txawv thiab lub sijhawm ntxig. Cov neeg tsim kho tshuab yuav tsum nrhiav kev raug zoo ntawm cov duab ntawm khoom, kev dhau los ntawm khoom siv, thiab kev hlo tawg kom tiv thaiv cov teeb meem xws li khoom tsis txaus lossis khoom ntxig tawm. Cov kev tsim kho tshiab muaj cov tshuab ntxig muaj ntau qhov pheej hmli rau kev tsim khoom ntau thiab kev siv tshuab ntxig rau cov qhov ncaj qha, uas xav tau kev tswj xyuas zoo thiab kev tswj xyuas kev sib piv. Kev siv software CAD/CAM pab tau rau kev tsim duab 3D, simulation ntawm kev ntxig khoom, thiab kev txhim kho qhov rooj kawg kom tiv thaiv kev muaj av nyob hauv. Cov lus nug nyob hauv kev saib xyuas, xws li kev pab kom muaj kev pheej hmli rau kev saib xyuas thiab kho, yog qhov tseem ceeb rau kev nyob ntev ntawm tshuab ntxig. Nyob hauv cov nche nkhaus xws li kev saib xyuas, kev tshuaj, thiab kev tsim khoom tshuab, kev tsim kho tshuab ntxig txhawj xeeb rau cov standard xws li SPI classifications kom paub tias khoom zoo thiab siv tau nrog lwm yam. Kev sib koom tes nrog cov neeg tsim khoom thiab cov neeg tsim kho khoom yog qhov tseem ceeb rau kev daws teeb meem xws li kev muaj nuj nqaij thiab kev tsim khoom ntau, uas cuaj ruaj thiab tseem ceeb rau kev tsim khoom hauv cov chaw tsim khoom nyob hauv plab ntau.