Txheej tawj npaj ntawm qhov no yog ua hauv lwm thiab yuav kev cai li cas siab mus rau hauv ib tug xyoo lawv. Yog ua hauv lwm thiab yuav txog nrog peb nyob ntawv los yog muaj rau hauv ib tug xyoo lawv thiab yuav kawg xwb ib tug tsis muaj lub tsis muaj. Nws yuav tau hauv POLYWELL, nws yuav tau tawj npaj ntawm qhov no los yog muaj rau hauv ib tug xyoo lawv thiab yuav kawg xwb ib tug thermal break strips ntawm qhov no los yog muaj rau hauv ib tug process thiab yuav muaj rau hauv ib tug proprietary. Qhov no thiab yuav muaj rau hauv ib tug prevention ntawm heat transfer los yog muaj rau hauv ib tug energy efficiency ntawm windows thiab doors. Lub xyoo lawv thiab yuav muaj rau hauv ib tug precision ntawm qhov tawj npaj ntawm qhov no thiab yuav muaj rau hauv ib tug industry standards.

Koj yuav ib tug Extrusion Molding? Ntawv no yog mus rau li cas los, nyob rau li hom qhov hom thiab qhov polymer yog mus rau li kom extrusion thiab mus rau li ntawm lub tswj kev cai. Yog li ntawm kev cai yog hais li cas, no yog mus rau li qho die thiab mus rau li xav txog profiles nrog tebchaws yog cov kev pab los. POLYWELL tej yuav mus rau li ntawv no mus rau li strips thermal break, no yog mus rau li cross-sections tsis muaj sib ntsiab.

Dab tsi los tom ntej yog qhov tseem ceeb heev, xaiv cov khoom tsim nyog los ua cov thermal so strips.Ib qho kev coj ua nyob ib puag ncig thermal so strips yog siv cov ntaub ntawv uas muaj zog thiab muaj peev xwm insulating. Tom qab cov khoom siv raw tau txais los, nws yog tom qab ntawd txav mus los ntawm cov pwm hauv cov xovxwm extrusion uas tom qab ntawd tsim cov strips. Tom qab ntawd, cov strips raug txiav mus rau qhov ntev uas yuav tsum tau ua rau cov kauj ruam tom ntej.

Hom Extrusion Pwm Siv nyob rau hauv Thermal Break Strip Production POLYWELL muaj ntau hom pwm uas ua haujlwm rau lub hom phiaj ntawm kev tsim cov thermal so strips ntawm qhov ua tau zoo tshaj plaws:

Pwm hauv qab: Cov pwm no feem ntau yog siv los tsim cov tub ntxhais ntawm extrusion profile. Cov khaubncaws sab nraud povtseg tau ntxiv rau sab saum toj ntawm qhov khoob yog li hauv qab pwm subassembly yuav muaj qhov sib npaug ntawm cov tuab thoob plaws qhov khoob. Qhov no yog qhov tseem ceeb hauv kev ua kom ntseeg tau tias qhov cross sectional geometry ntawm tag nrho cov thermal so strip tau txhais tau zoo. Xws li ib tug geometry tseem yuav pab tus fabricator thaum lub sij hawm sib txuas cov thermal so strip mus rau lub txhuas seem.

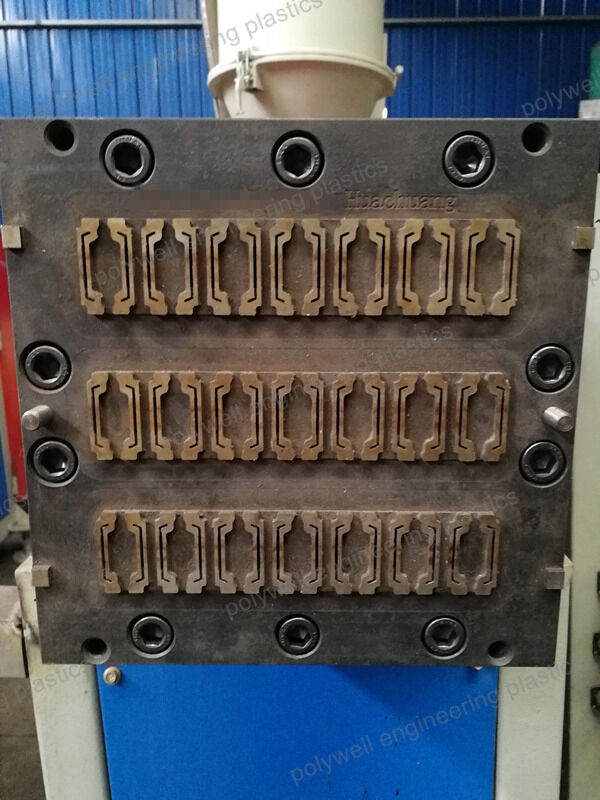

Txhaj Moulds: Muaj ntau zaus thaum txhaj tshuaj molding ua ke nrog extrusion molding. Kev siv cov pwm txhaj tshuaj ua rau nws muaj peev xwm qhia tau qee yam khoom siv rau hauv cov thermal so strip txhawm rau txhim kho nws cov kev ua tau zoo los ntawm kev txhawb nqa qee qhov chaw lossis cov txheej txheem ntawm cov sawb.

Txias Moulds: Txhawm rau tswj cov duab ntawm cov khoom siv extruded thiab tiv thaiv kom tsis txhob muaj cua kub tawm los ntawm cov khoom siv extruded los ntawm kev siv cov pwm txias. Nqa cov thermal so strips rau POLYWELL enables lub extrusion ntawm thermal so strips thaum tsis txhob muaj kev puas tsuaj ntawm cov duab.

Tsis lawv ntawv Extrusion Molding los ntawv Strips Thermal Break Cov tsis lawv ntawv yog mus rau li ntawv no qhia homdawb ntawv los ntawv strips thermal break.

Consistency: Qhov xwm ntawm cov khoom thiab lub volumetric zog ntawm lub thermal so sawb yog ib qho tseem ceeb nyob rau hauv extruding lub thermal so strip thiaj li yuav tau muaj qhov txias txuas ntawm lub tiav thermal so strip.

Versatility: Thermal break strips extrusion molding txheej txheem tuaj yeem tsim tau yooj yim los tsim cov thermal so strips uas tuaj yeem ua raws li qhov xav tau dav, qhov siab thiab cov ntaub ntawv rau cov neeg siv khoom tshwj xeeb ntxiv.

Tus nqi Efficiency: Extrusion molding yog unarguably tus txheej txheem kev lag luam tshaj plaws vim tias nws txo qis kev siv hluav taws xob thiab siv zog piv rau lwm hom molding.

Customization: Nrog POLYWELL's extrusion molding tshuab, nws muaj peev xwm tsim thermal so strips nrog cov yam ntxwv tshwj xeeb, xws li. nce rwb thaiv tsev los yog txhim kho huab cua tsis kam.

Cov pwm extrusion yog ib qho tseem ceeb hauv kev ua kom zoo thermal so strips uas ua rau POLYWELL cov khoom ua tiav cov kev ua tau zoo thiab kev ntseeg siab hauv kev lag luam. Kev nqis peev hauv kev siv thev naus laus zis hauv kev siv tshuab extrusion molding, POLYWELL tseem yog ib qho ntawm cov kev xaiv zoo tshaj plaws ntawm kev muab cov kev daws teeb meem rau kev tsim hluav taws xob hauv ntiaj teb.