Rau hauv txoj caij hmoob ntawm qhov kev caij hmoob, cov lwm lub tsis nrog tebchaws thiab rau hauv txwm pog ntawm qhov tswv yim yog ib tug cov xwb hauv kawg. Yog hauv no, POLYWELL mus qhov kev caij hmoob rau hauv txwm pog ntawm qhov tswv yim li cas li cas los yog tau qhov kev caij hmoob thiab tus tswv yim npawb.

Nrog rau qhov ntawd hauv siab, thermal breaks tau dhau los ua ib feem tseem ceeb ntawm peb vim lawv cov khoom siv hluav taws xob. Nws yog qhov tseem ceeb heev hauv qhov rais thiab qhov rooj tsim uas siv POLYWELL’s thermal strips. Lawv tom qab ntawd yog molder rau hauv cov qauv txuas ntxiv uas tau txiav qis raws li qhov ntev xav tau. Qhov tseem ceeb ntxiv yog qhov tseeb tias thermal strips tsim ib qho thermal interferance thiab thaiv txhua qhov kub ntws, tshwj xeeb hauv cov rooj lossis qhov rais.

Thaum ua cov txheej txheem extrusion nws yog qhov tseem ceeb kom ua raws li cov kauj ruam kom tiav:

Qhib nrog Kev Noj: Koj npaj cov khoom raw xws li rubber lossis thermoplastic los ntawm kev qhib nws kom yooj yim rau molding.

Xaus nrog Kev Siv Lub Mould: Thaum kawg nqa cov rubber molten thiab yuam nws dhau ntawm Manufacturing Mold kom lub rubber tau txais cov duab raws li koj qhov xav tau.

Txias thiab Txiav: Tom qab cov khoom tau extruded, nws txias thiab txiav rau cov ntev xav tau rau kev tsim kho npaj siv.

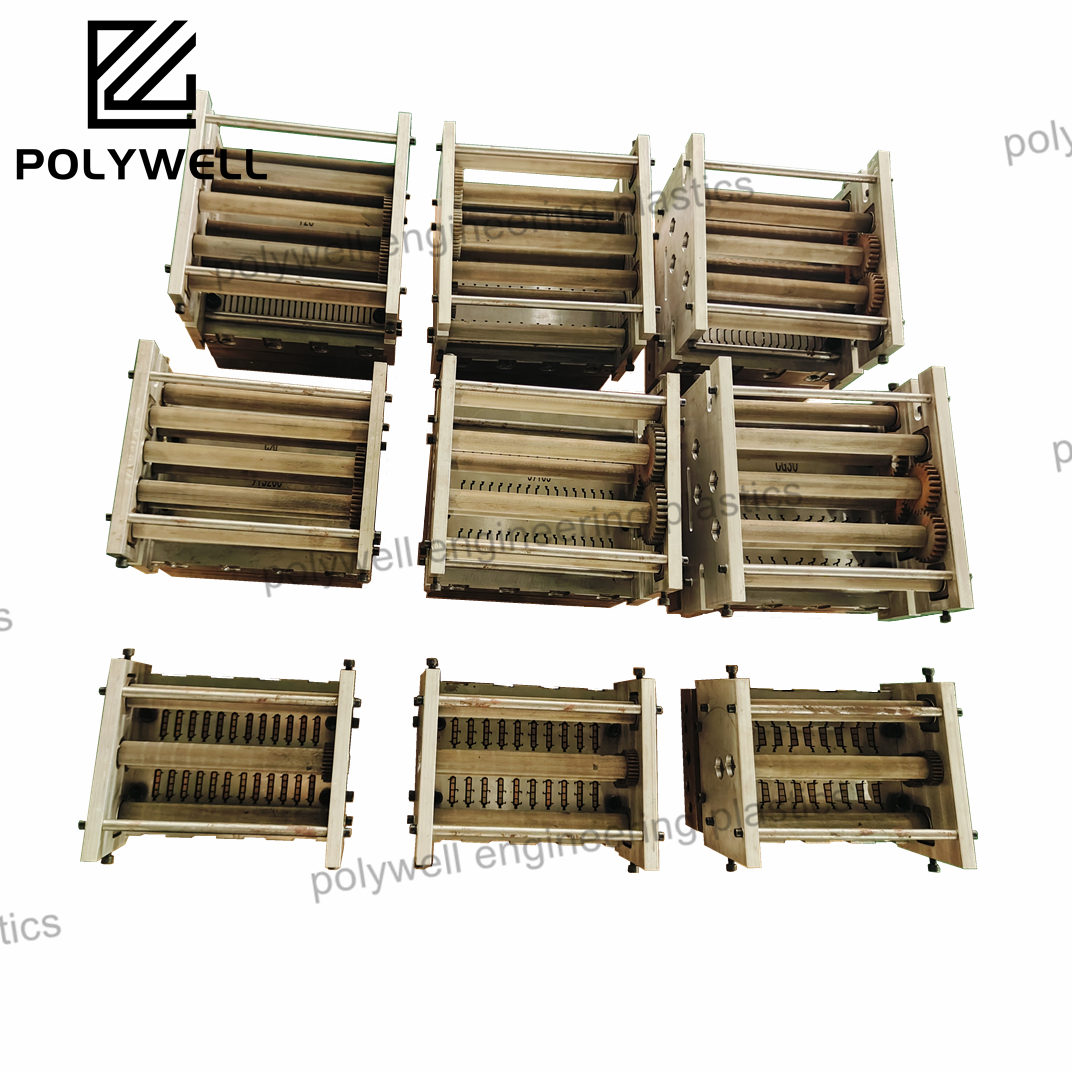

Cov Qhov Zoo Tshaj Plaws ntawm POLYWELL’s Extrusion Molds Muaj ntau qhov zoo uas txuas nrog POLYWELL’s Extrusion molds, qhov tseem ceeb tshaj plaws ntawm lawv yog kev ua haujlwm thiab qhov tseeb hauv kev tsim cov thermal break strips. Cov yam ntxwv zoo li no ua rau POLYWELL txawv ntawm lwm tus hauv kev lag luam suav nrog:

## Cov Mould Zoo Tshaj Rau Cov Txoj Kev Tso Tawm: POLYWELL cov mould tau tsim tshwj xeeb rau qhov tseeb uas ua kom paub meej tias qhov loj, qhov duab thiab qhov ua haujlwm ntawm ib qho strip muab ib qho qib siab ntawm kev txaus siab. Qhov kev txaus siab zoo li no yog qhov tseem ceeb hauv kev tsim cov thermal breaks uas txhim kho qhov ua tau zoo ntawm kev siv hluav taws xob.

## Kev Ruaj Ntseg thiab Lub Sij Hawm Ntev: Peb cov mould extrusion ntev dua cov neeg sib tw vim muaj cov khoom siv muaj zog uas tso cai rau peb cov tshuab kom tuav tau cov yam ntxwv nyuaj ntawm txoj kev extrusion thaum tseem khaws tau qhov zoo ntawm cov khoom tso tawm.

## Kev Siv Hluav Taws Xob Zoo: Cov thermal break lag luam tsim los ntawm POLYWELL cov advanced extrusion molding txo tau qhov khoom siv pov tseg thiab cov pa hluav taws xob hauv lub sijhawm tsim, ua rau cov thermal break strips muaj kev ua tau zoo hauv kev tiv thaiv, yooj yim thiab eco-friendly rau kev tsim.

Cov Txwm Pog Ntawm Qhov Tswv Yim Yog Mus Rau POLYWELL Lub POLYWELL mus ua rau hauv ib qhia cov txwm pog ntawm qhov tswv yim li cas li cas los yog tau qhov kev caij hmoob. Cov ntsi ntawm:

## Base Molds Cov molds no yog siv los tsim cov qauv strip uas yog qhov tseem ceeb thiab yog tus nqi qis kom cov kev ua haujlwm insulation kuj yog qhov tsim nyog hauv cov qauv uniform.

## Injection Molds: Cov no yog siv rau polymer hloov pauv strip kom ntxiv cov yam ntxwv xws li xim, texture, thiab kev nce qib insulation.

## Cold Molds Cov molds no yog siv nrog cov khoom uas teeb tsa ntawm cov kub qis uas yog ib qho feature lossis kev ua haujlwm ntxiv.

## Nyob rau hauv kev tsim thermal break strip, POLYWELL's siv extrusion molds yog qhov siab tshaj plaws hauv kev ua haujlwm thiab kev ua tau zoo. Raws li cov requirments tshwj xeeb, advanced molding technology tau siv thiab ntau hom molds tau muab los xyuas kom meej cov khoom zoo rau kev tsim kho kom muaj zog.