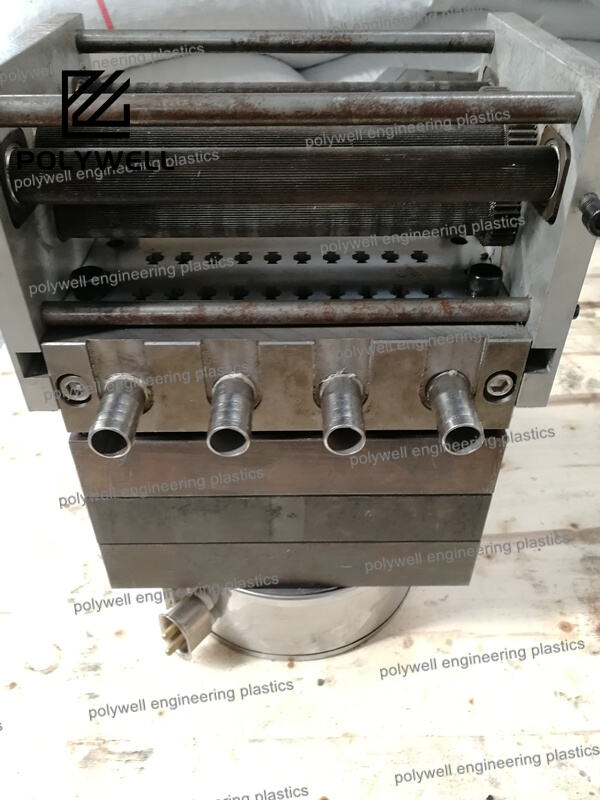

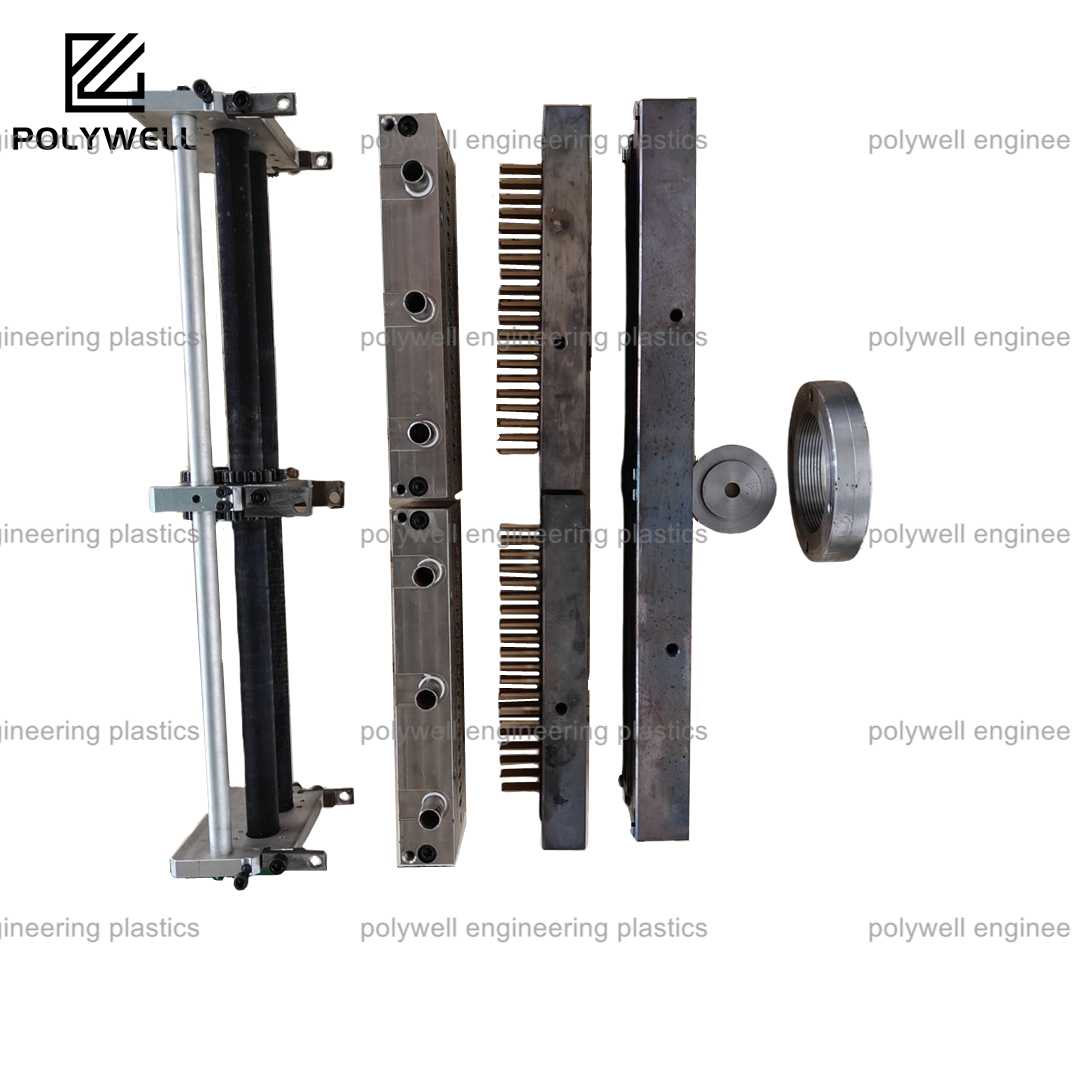

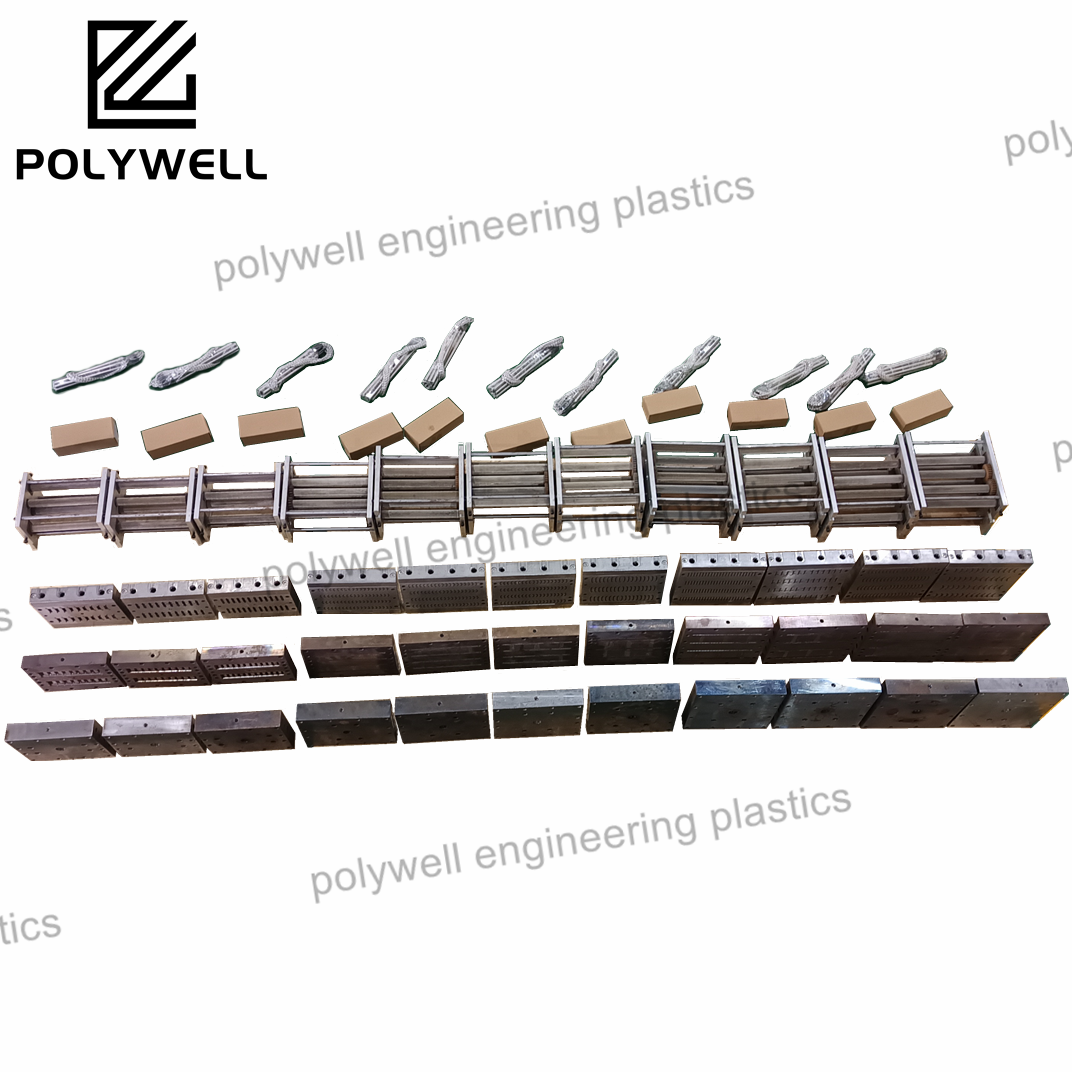

Kev tsim kho tshuab die thiab mold yog qhov kev kawm txog kev tsim kho tshuab rau kev tsim kho tshuab ntau, uas muaj kev tsim kho cov tshuab rau kev tsim kho tshuab rau kev ua metal (die) thiab kev tsim kho tshuab rau plastic (mold). Qhov kev kawm no xav tau kev paub meej meej txog yam ntxoov ntxoo, kev daws teeb meem thermal, thiab lwm yam ntawv tshuab. Kev tsim kho nyob rau hauv qhov kev suav xyuas meej meej txog qhov kev tsim kho tshuab, siv cov lus tshuaj xam txog kev tsim kho tshuab los nrhiav thiab daws cov teeb meem tshuab tshiab. Rau kev tsim kho tshuab die casting, qhov kev tsim kho yog tshuab rau kev co tsev lub zog ntawm dej sov, kev puas tsuaj ntawm kws tshuab, thiab kev cuam tshwv, nrog rau kev pom zoo rau cov tshuab tso dej, cov av tsha, thiab kev txhim kho tshuab tso dej. Rau kev tsim kho tshuab injection molding, qhov tshuab yog rau kev co tsev polymer, kev kho kom raug rau kev lag, thiab kev tsim kho tshuab tso tshuab tawm. Cov ntsiab lus txaus siab yog qhov chaw cavity thiab core system uas sau qhov geometry ntawm tshuab, cov tshuab tso khoom mus, cov tshuab saib xyuas teb temperature kom tsis txuas, thiab cov tshuab tso tshuab tawm. Kev xaiv yam khoom yog ib qhov tseem ceeb, yam khoom steel yog xaiv raws li kev xav tau ntawm kev tsim kho—kev txaus siab rau kev puas tsuaj ntawm kws tshuab rau die casting, kev txaus siab rau yam khoom xwm, thiab kev txaus siab rau kev saum npaum. Kev tsim kho tshiab siv siv software CAD/CAE rau kev tsim kho 3D, simulation, thiab kev suav xyuas tshuab. Qhov kev tsim kho tseem xav tau kev xav txog cov teeb meem nyob ze, xws li kev ua haujlwm ntev, kev tshuab tshiab, thiab kev raug rau cov tshuab tsim kho. Rau kev tsim kho ntau, die thiab mold tsim kho muaj kev tsim kho tshuab txaus, kev tshuab tshiab txaus, thiab kev tso dej txaus siab kom tshuab tshiab. Qhov kev tsim kho die thiab mold zoo tuaj yeem tsim kho tshuab uas tsim kho tshuab nrog qhov tseem ceeb, qhov ntev raug, thiab qhov surface finish zoo, thaum kuj tseem pheej tua kev tsim kho los ntawm kev ntev dua, kev lom zog tsawg dua, thiab kev lag khoom tsawg dua. Qhov kev kawm no yog qhov tseem ceeb tshaj plaws ntawm kev tsim kho tshuab thiab kev tsim kho tshuab nyob rau hauv qhov kev tsim kho tshuab automotive, khoom siv hauv tsev, khoom tshuab tshiab, thiab electronics nyob rau hauv lub ntiaj teb.