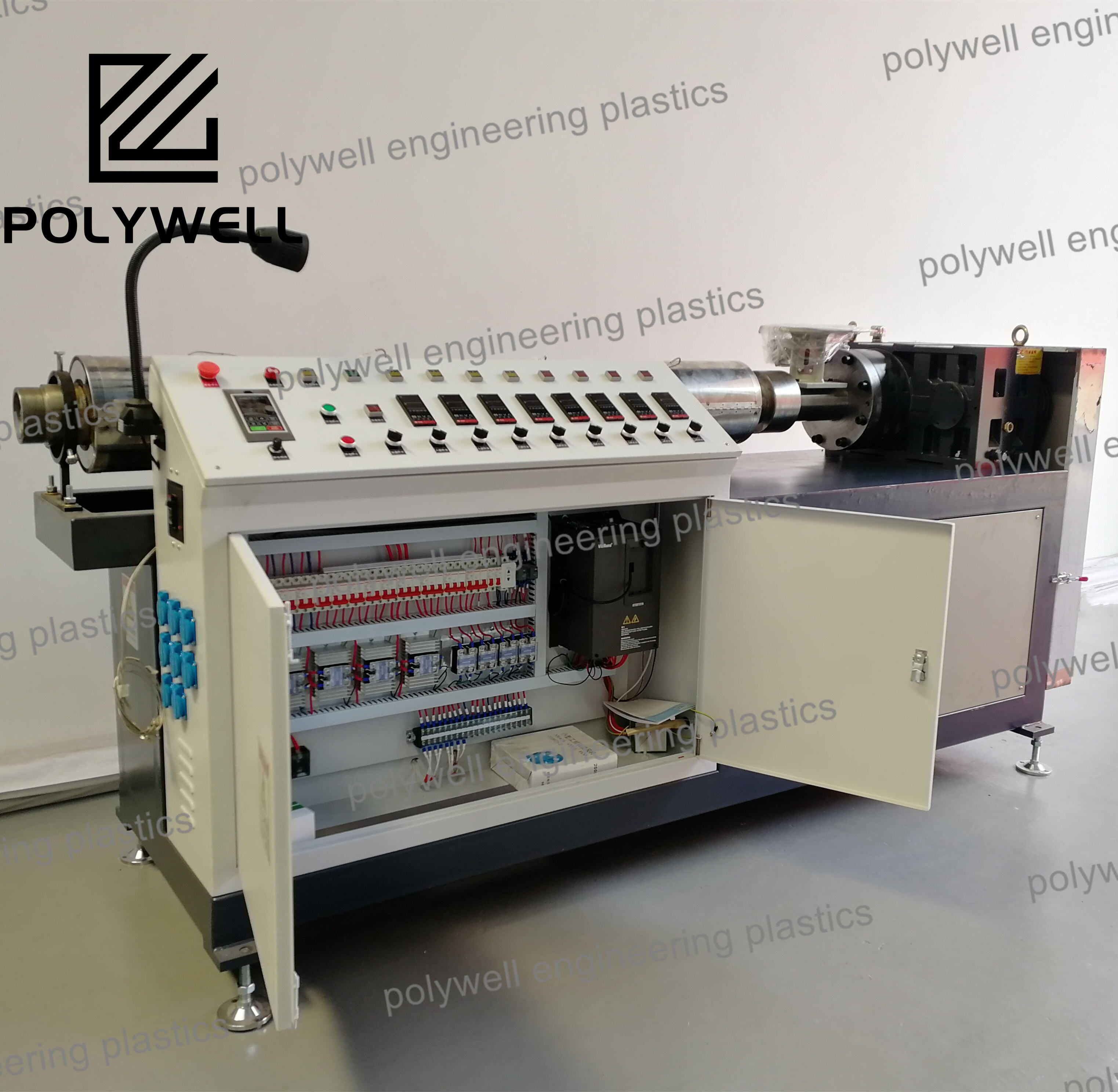

Brabender single screw extruders yog qhov chaw tsim kho tshuab siv rau hauv laboratory thiab rau qhov chaw thíb pom muaj nuj nqi rau kev xam txheej, kev tsim kho tshuab thiab kev daws teeb meem nyob hauv cheeb tsam tsim kho tshuab polymer. Qhov chaw tsim tshuab no los ntawm Tebwl muaj kev tu zoo tshaj plaws thiab kev suav ntau yam ntaub ntawv uas pab tau zoo rau kev xam txheej tshuab, kev tsim kho tshuab thiab kev sim qhov kev tsim kho tshuab. Cov chaw tsim tshuab feem ntau muaj lub ntsiab lus ntawm 19mm mus rau 30mm thiab muaj lub ntsiab lus sib txawv (feem ntau yog 20:1 mus rau 25:1) uas raug xaiv tshaj plaws rau cov tshuab siv sib txawv thiab kev xam txheej. Qhov kev tsim kho tshuab uas tuaj yeem hloov pauv tau pab tshuab hloov pauv ntau yam los ntawm kev siv cov ntsiab hloov pauv, cov ntsiab tawv thiab cov khoom siv tom qab uas tshyer tias muaj kev tsim kho tshuab. Cov DC drive precision muaj kev tu zoo tshaj plaws thiab muaj kev suav torque, thaum cov ntsiab tawv muaj kev tu ncua nruj thiab muaj kev tu ncua nruj nrog kev tu ncua nruj nrog ±1°C. Cov software systems uas tau xaiv tshwj xeej tuaj yeem suav thiab suav ntau yam ntaub ntawv xam txheej xws li melt pressure, temperature, motor torque, thiab output rate, uas pab tau zoo rau kev xam txheej tshuab. Cov kev siv tshuab tshwj xeej xws li kev xam txheej qhov kev xam txheej, kev xam txheej kev tu ncua nruj thiab shear stability, kev xam txheej cov tshuab siv tshiab, thiab kev sim qhov kev tsim kho tshuab rau cov tshuab siv tshiab. Qhov kev tsim kho tshuab tseem ceeb pab tau zoo rau kev tsim kho tshuab tshiab thiab kev daws teeb meem nyob hauv chaw tsim kho tshuab. Lub tshuab tsim kho tshuab tseem ceeb pab tau zoo rau kev tsim kho tshuab tshiab thiab kev daws teeb meem nyob hauv chaw tsim kho tshuab. Lub tshuab tsim kho tshuab tseem ceeb pab tau zoo rau kev tsim kho tshuab tshiab thiab kev daws teeb meem nyob hauv chaw tsim kho tshuab.