Engineering Plastic 14.8-35.3mm Hollow Profile Polyamide PA66 Extrusion Thermal Break Strip

Nylon Chain Guide Profile Rail Guide Runway Guide PA66 Profile

- Overview

- Recommended Products

What is a thermal break strip?

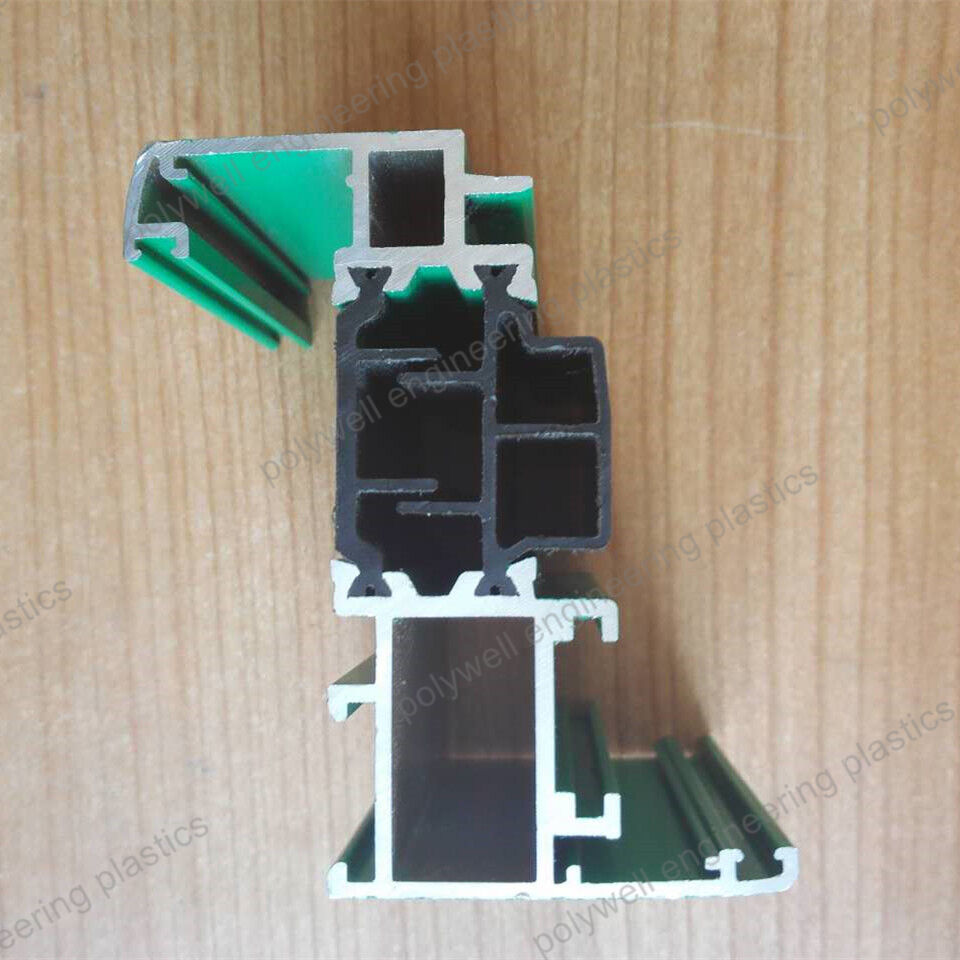

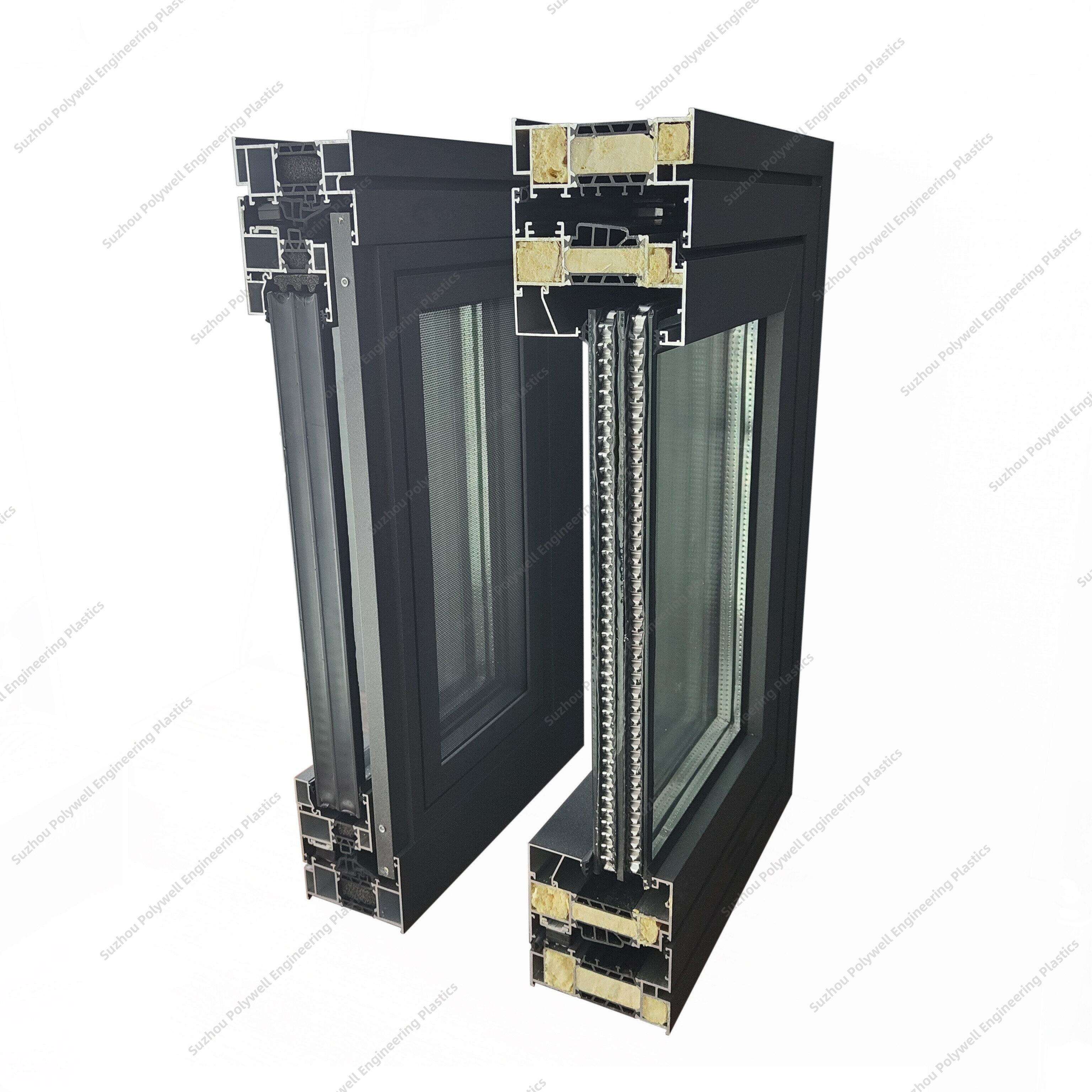

Thermal break strip, also called heat insulation strip, is a part of aluminum bridge profile. The heat-insulating bridge aluminum-plastic profile can realize the three-way sealing structure of doors and windows, and reasonably separate the water vapor chamber. It successfully realizes the pressure equalization of gas and water, and significantly improves the watertightness and airtightness of the doors and windows.

Insulation of aluminum doors and windows sealed with insulation strip is the one with the glass fiber reinforced polyamide nylon (PA66), referred to as Nylon 66 insulation strips, expansion coefficient is small, heat-resistant, and anti-aging properties.

Inserted in the thermal break aluminium profiles, and being the part of energy-saving window system for reducing heat conduction.

The shape I polyamide thermal barrier material can prevent the window frame from dust and water and could realize a better Uf value by sealing with a rubber profile, mostly used on the sash.

What are the different types of polyamides?

Polyamide (PA) is among the most important and proven technical thermoplastics, known for their heat resistance, stiffness and high mechanical stability Polyamides can be classified into different types, with PA 6, PA 6.6 and PA 12 most established on the market.

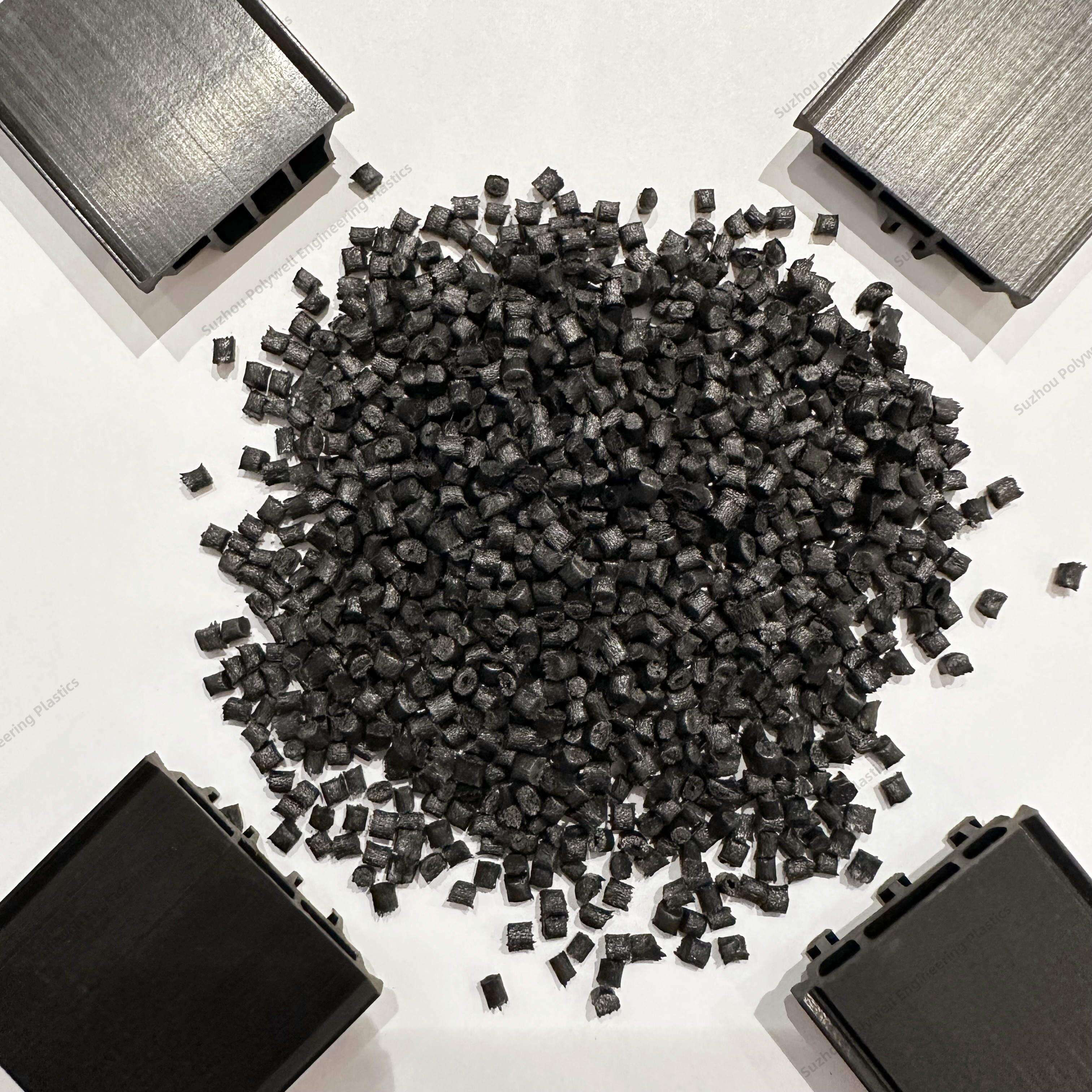

Our polyamide strips are made of PA6.6 reinforced by 25% fiberglass.

The Function of Thermal Break Strips in Window

Broken bridge heat-insulated aluminum alloy doors and windows is to divide the original whole-body aluminum alloy profile into two on the basis of traditional aluminum alloy doors and windows. The overall heat-insulating profile enables the heat-insulating strip and the aluminum alloy to jointly bear the load caused by the glass's own weight, wind pressure and temperature stress. Therefore, the use nature of the heat insulation strip determines that it must have high strength and excellent stability at the same time, otherwise it will easily cause doors, windows and curtain walls to break and fall off, causing major quality and safety hazards.

The word "bridge" in the name "broken bridge aluminum" means "hot and cold bridge" in material science, and the word "broken" stands for action words, which means "cut off the hot and cold bridge". Specifically speaking, aluminum alloy is a metal medium with strong thermal conductivity. When it collides with the temperature outside the house by a large difference, the aluminum alloy becomes a "bridge" for heat transfer. Using this type of material to make doors and windows, it will have Poor insulation too. However, the broken bridge aluminum is to disconnect the aluminum alloy from the middle, and the thermal conductivity of the plastic will be weaker than that of the metal. The disconnected aluminum alloy is connected together with hard plastic, so that the heat will not easily flow to the whole. material, so the heat insulation will become better, which is the origin of the name "broken bridge aluminum (alloy)".

Advantages of polyamide strips

The polyamide strip is a material of low thermal conductivity which will minimise the transfer of heat and cold through the window frame, resulting in improved energy efficiency. The polyamide strip will have a HUGE impact in reducing transfer of heat and cold over typical non-thermal profiles. These sections can be anodized or powder coated to withstand the harsh climate, including UV damage and salt corrosion.

The wider the thermal break, the greater insulation performance.

Thermally Broken windows are a major contribution to sustainable and eco-friendly homes. They help to save money, energy and support the environment.

Application of polyamide strip:

1. Used for thermal break aluminum window, door, curtain and walls.

2. Many customer use thermal break aluminum profile to do big air conditioner to keep heat of cold air, then make use of energy saving.

Characteristic of polyamide strips

Polyamide thermal breaks are extruded in dry state but they absorb moisture from the environment after the production as time passes. Moisture level depend the following conditions:

- Ambient temperature

- Ambient humidity

- Storage period

During the summer time, when the temperature and humidity in storage area are higher than usual, the insulating profiles absorb more moisture than in the remaining seasons, even stored properly.

Package of polyamide thermal break strips

Conventional straight package: 6m per piece. Cutting length can also be customized based on customer’s requirements.

Roll package: 300-500 meters per roll, limited to type I and type C.

According to the specific requirements of customers, large-scale production, packaging and computer laser code printing can be carried out.

Our service

1. Expertise in the production of standard polyamide thermal break strips.

2. Respect customers' needs, provide customized products, try best to satisfy customers' requirements.

3. Fast service and on-time delivery.

4. Strict quality control system, each production process will be strictly supervised by us.

5. We can provide all products on the insulation strip production line and the technical support.

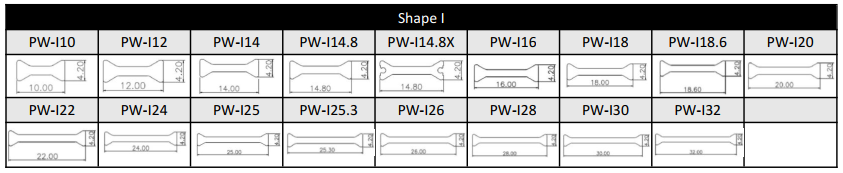

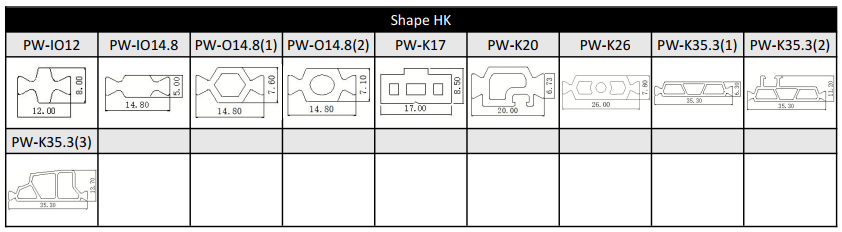

Different shapes:

I-type thermal break strip is a common insulation material for doors and windows, with a shape similar to the uppercase English letter "I". It is the first generation and easiest shape of polyamide strips.

Compared to other types of thermal break strips, the advantage of I-type strips is that their longer length can better adapt to the width of doors and windows, improving the thermal break effect.

In addition, Type I insulation strips can also adapt to different door and window sizes and specifications through their own shape and structure, with high flexibility and adaptability.

For the I-type strips, we can provide the following size or customize according to customer’s drawing.

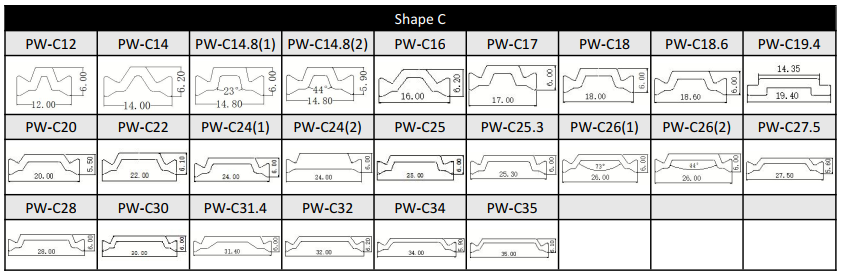

The C-type design provides a longer heat conduction path, resulting in better heat insulation performance than I-type strip, while also having better longitudinal load-bearing capacity. Besides, the C-type PA strip is also a necessary condition for the stepped drainage of thermal broken bridge aluminum.

For the C-type strip, we can provide the following size or customize according to customer's drawing.

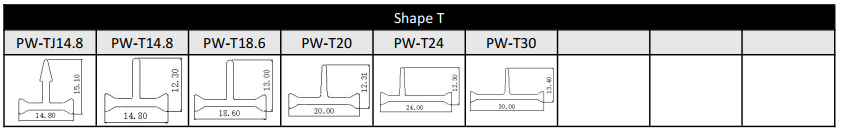

The design of T-type thermal break strips usually includes a horizontal section and a vertical section, forming a "T" - shaped structure.

This design adds a small section under the thermal break strip, allowing the sealing strip to overlap with the thermal break strips, thereby improving the overall insulation performance.

For the T-type strip, we can provide the following size or customize according to customer's drawing.

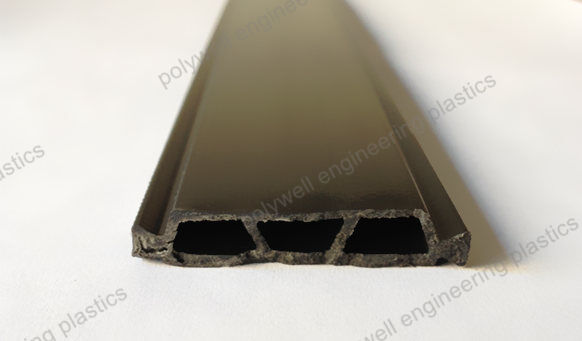

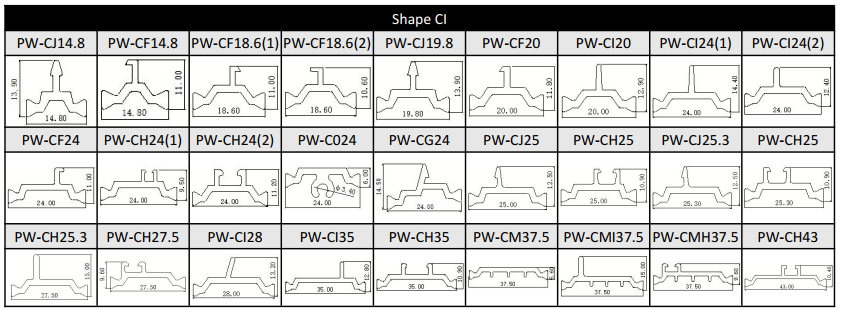

Hollow thermal break strip, also known as multi-cavity insulation strip, can reduce heat transfer by changing the air flow path, thereby achieving insulation effect and further improving insulation performance.

Hollow thermal break strip are currently the mainstream products in the market and can support large width sizes. Many thermal break strips with a diameter of 35mm or more on the market are made into multi-cavity shapes, and their longitudinal load-bearing capacity is very high.

For the hollow type strip, we can provide the following size or customize according to customer's drawing.

Product Performance

Item |

Unit |

GB/T 23615.1-2009 |

PW-Technical specification |

Density |

g/cm3 |

1.3±0.05 |

1.28-1.35 |

Linear expansion coefficient |

K-1 |

(2.3-3.5)×10-5 |

(2.3-3.5)×10-5 |

Vicat softening temperature |

ºC |

≥230 |

≥233 |

Melting point |

ºC |

≥240 |

≥240 |

Testing for tensile cracks |

- |

No cracks |

No cracks |

Shore hardness |

- |

80±5 |

77-85 |

Impact strength(Unnotched) |

KJ/m2 |

≥35 |

≥38 |

Tensile strength(longitudinal) |

MPa |

≥80a |

≥82a |

Elasticity modulus |

MPa |

≥4500 |

≥4550 |

Elongation at break |

% |

≥2.5 |

≥2.6 |

Tensile strength(transverse) |

MPa |

≥70a |

≥70a |

High temperature tensile strength(transverse) |

MPa |

≥45a |

≥47a |

Low temperature tensile strength(transverse) |

MPa |

≥80a |

≥81a |

Water resistance tensile strength(transverse) |

MPa |

≥35a |

≥35a |

Aging resistance tensile strength(transverse) |

MPa |

≥50a |

≥50a |

1. Sample water content less than 0.2% by weight.

2. Norm laboratory condition:(23±2)ºC and (50±10)% relative humidity.

3. The specifications marked with "a" only applies to I-shape strip otherwise, the specifications concluded between supplier and buyer through consultation, shall be written in contract or purchase order.

EN

EN