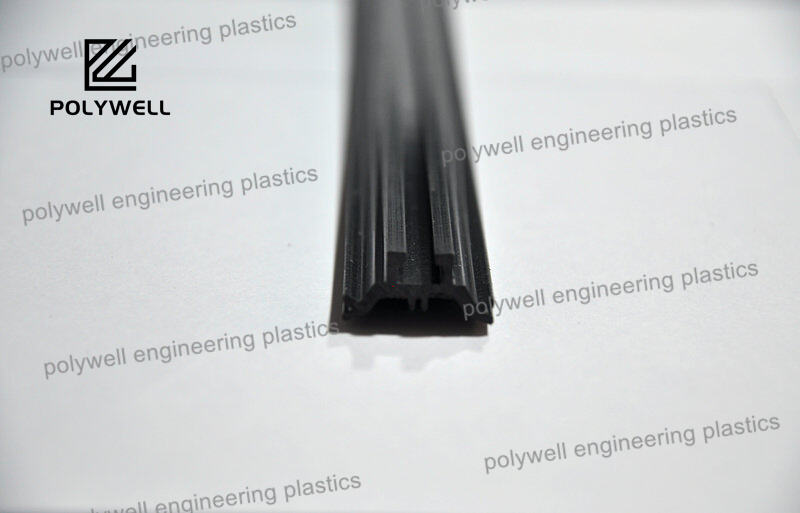

Thermal bridging solutions encompass a range of design strategies, construction techniques, and specialized materials aimed at eliminating or minimizing the negative impacts of thermal bridges in building envelopes. The overarching goal is to create a continuous thermal barrier that is as uninterrupted as possible. One of the most critical solutions is the use of thermally broken profiles for windows, doors, and curtain walls. This involves inserting a high-strength, low-conductivity polymer strip (e.g., PA66 GF30) within the aluminum or steel frame to separate the interior and exterior metal. For structural connections, such as balcony slabs or cantilevered beams, structural thermal break materials are employed. These are robust, compression-resistant panels, often made of glass-fiber reinforced polymer or dense composite materials, that are installed at the point of connection to isolate the conductive element. Another fundamental solution is the principle of continuous insulation (ci), where the insulation layer is installed externally and without gaps over the entire building facade, covering structural elements like studs and concrete members that would otherwise create bridges. Careful architectural detailing is also a solution; for example, using non-conductive spacers and fasteners for cladding attachments, and designing junctions between walls, roofs, and floors to maintain the insulation line. Advanced modeling software, such as thermal analysis programs, is used as a predictive solution to identify and rectify potential bridges during the design phase. The implementation of these solutions is not merely a technical exercise but a fundamental requirement for achieving high levels of energy efficiency, ensuring occupant comfort and health, and constructing durable, long-lasting buildings that meet modern performance standards.